High-torque hydraulic pipe-wrenching machine for wrenching and disassembling outer-flat drilling rod

A high-torque, pipe twisting machine technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problem of unscrewing and unloading the axial floating of the drill pipe well, the pipe twisting machine has no automatic centering function, and the drill Rod and equipment life impact and other issues, to achieve the effect of reducing labor intensity of workers, large torque, reliable and safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

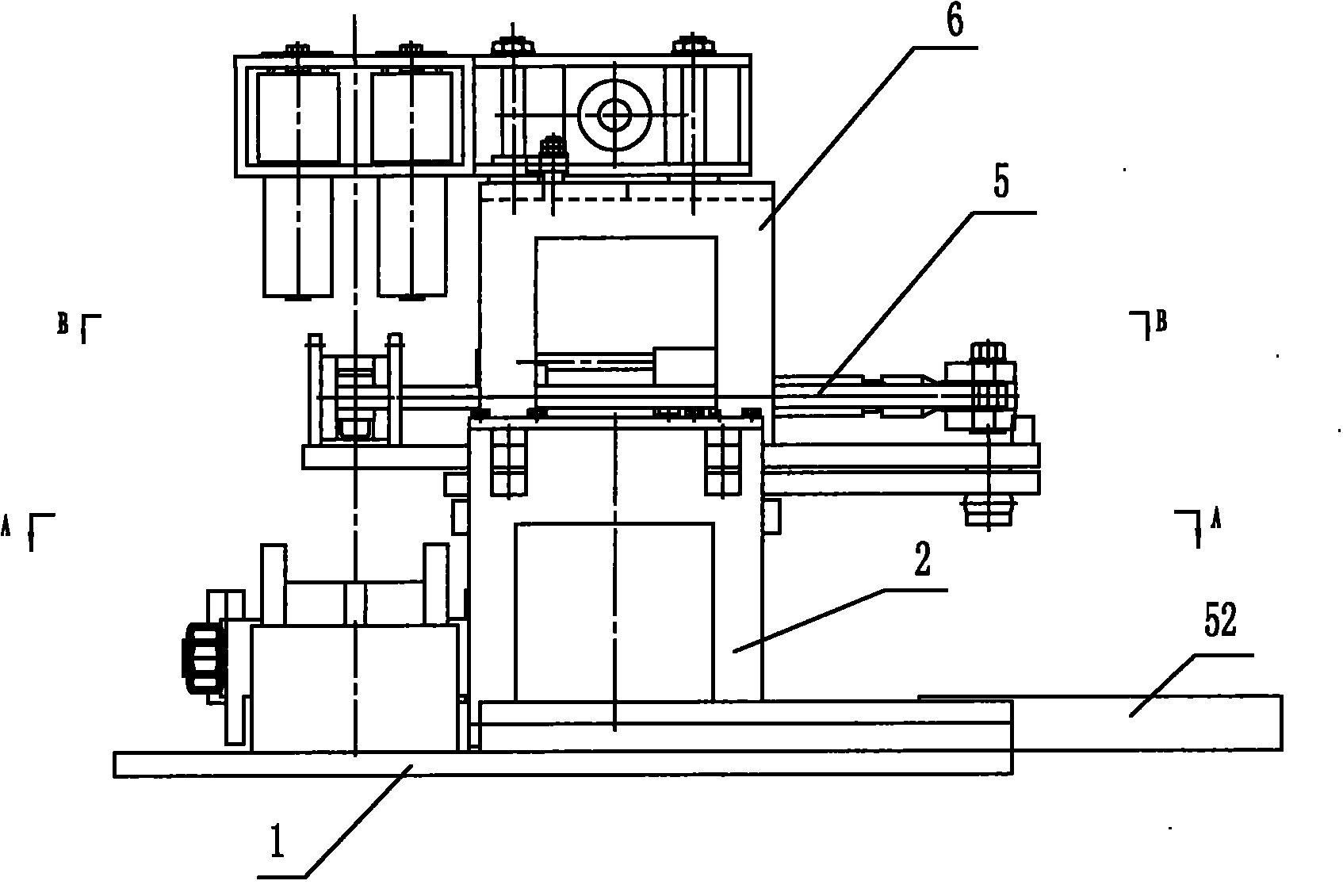

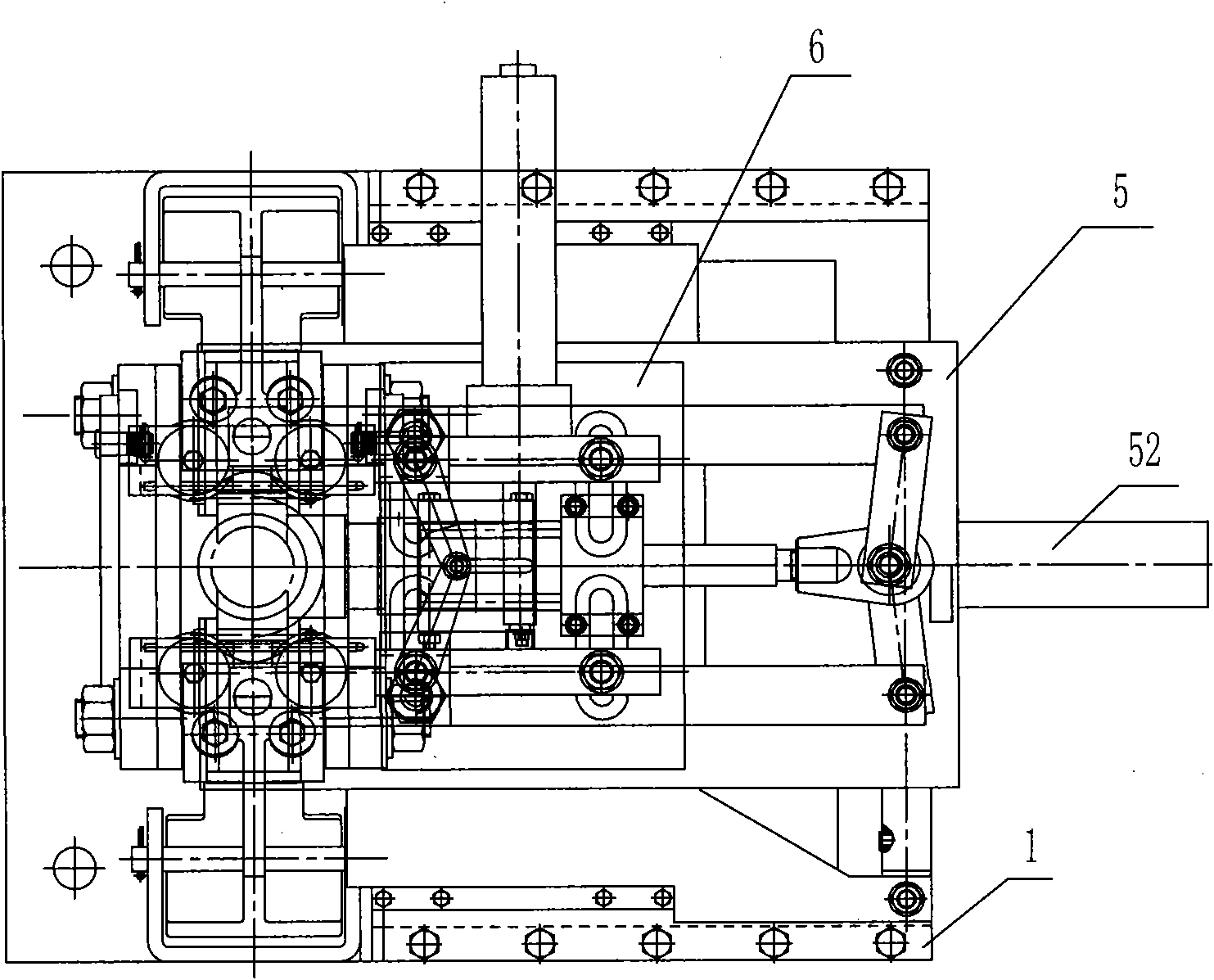

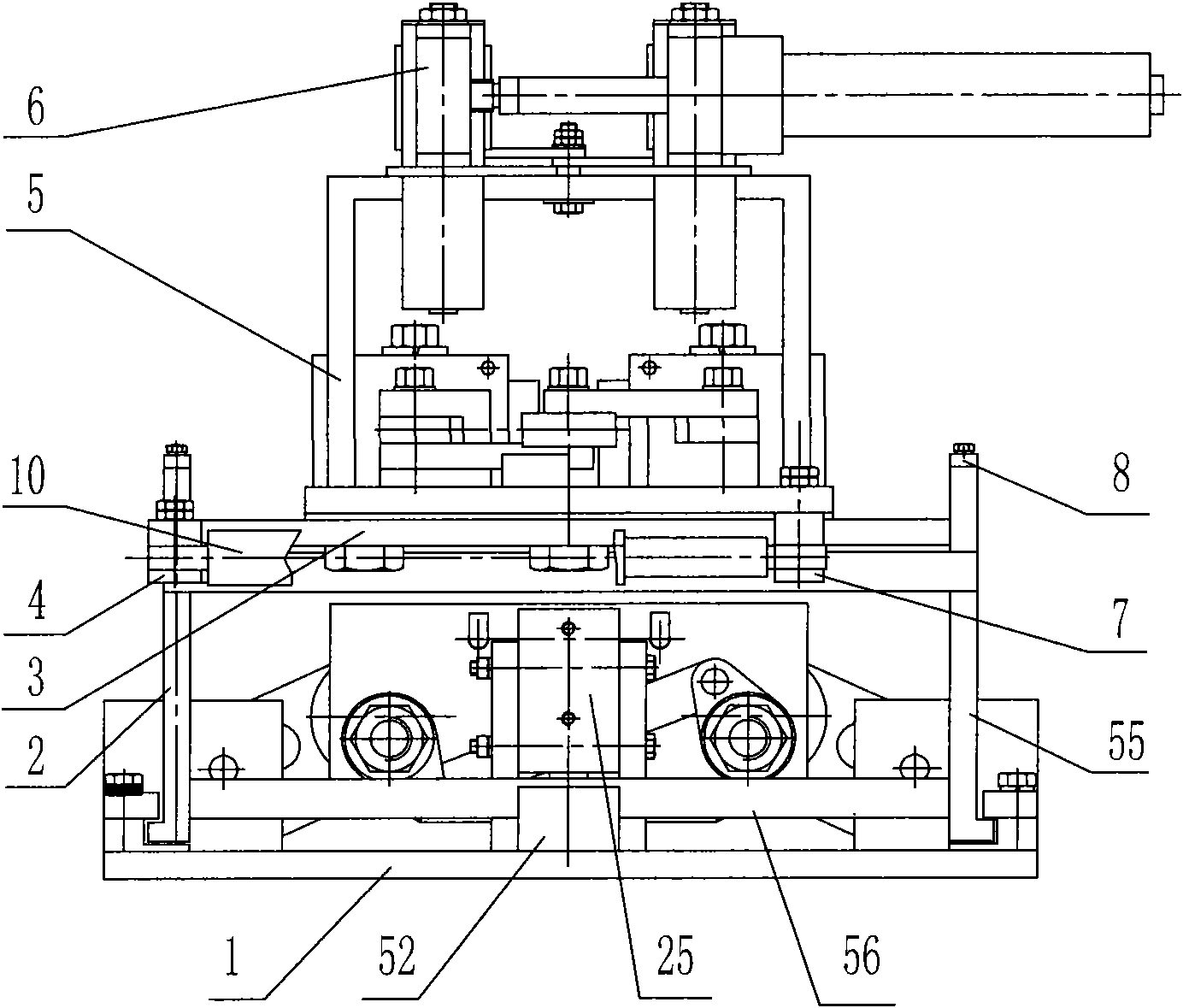

[0043] The high-torque hydraulic pipe twisting machine used for unscrewing and unloading the outer flat drill pipe of the present invention mainly consists of the following parts:

[0044] (1) Lower clamping pliers: The lower clamping pliers clamp the drill pipe in the hole, support the self-weight of the drill pipe in the hole, overcome the pre-tightening or punching torque, and prevent the upper drill pipe from rotating or slipping in the hole. .

[0045] (2) Punching pliers: In order to prevent the drill pipe from breaking or falling due to the lack of pre-tightening force of the threaded thread of the downhole drill pipe during the drilling process, the pre-tightening force should be applied to the drill pipe when drilling; in addition, During the rod unloading process, due to the large torque between the threaded threads, it is necessary to unscrew the first turn of the threaded thread by punching pliers. The buckle pliers 5 complete the high-torque preload and buckle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com