A method of heightening and expanding the volume of ultra-fine tailings reservoir with one-time dam construction using the center line method

A technology for tailings storage and ultra-fine particles, which is applied in the field of heightening and expansion of ultra-fine tailings storage, and can solve the problems of low mechanical strength, long consolidation time, and high safety risks of ultra-fine particle tailings dam construction, etc. Achieve the effects of prolonging the production service life, increasing the storage capacity, and increasing the stacking height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

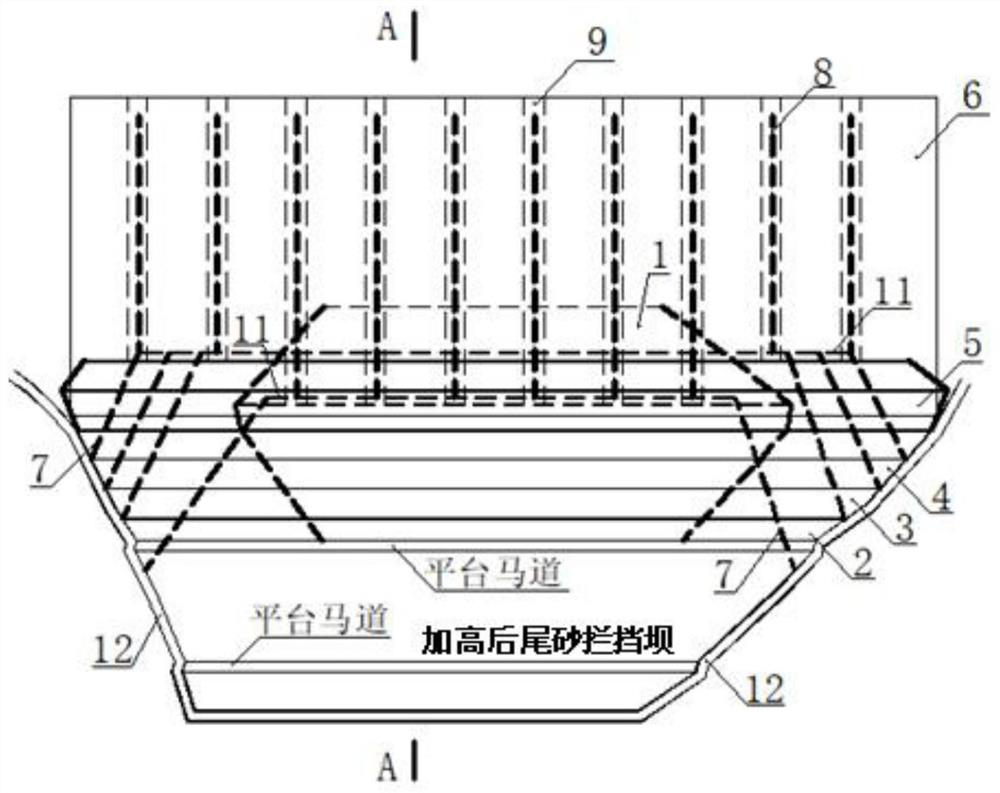

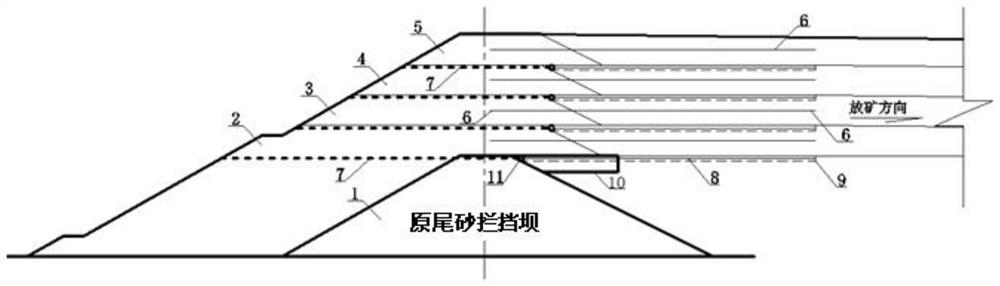

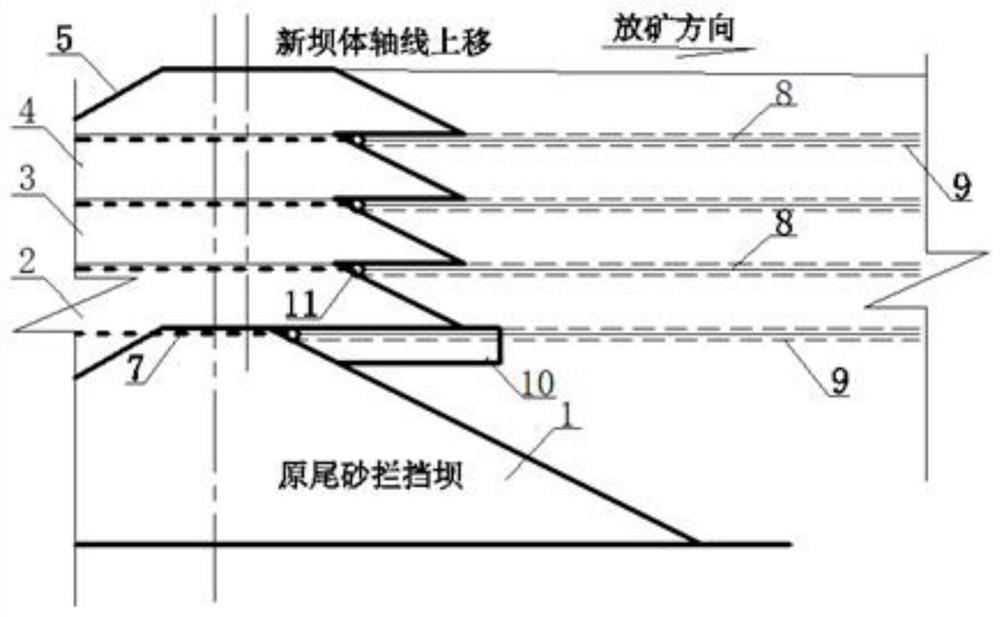

[0033] In order to better describe the present invention, the method for heightening and expanding the volume of the superfine tailings reservoir for one-time dam construction in the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] Depend on figure 1 The shown ultra-fine tailings reservoir of the present invention for one-time dam construction adopts the method plane layout schematic diagram of heightening and expanding capacity by the center line method and combines figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the ultra-fine tailings pond of the present invention adopts the method of increasing the height and expanding capacity of the midline method, and contains the original tailings retaining dam 1 and the abutment intercepting flood ditch 12. The original tailings retaining dam 1 is a disposable The roller compacted earth-rock retaining dam is built with the center line method, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com