A reverse seepage drainage system suitable for upstream tailings pond and upstream tailings pond

A tailings pond, upstream technology, applied in the field of seepage drainage system, can solve the problems of difficult construction and cost control, and achieve the effects of improving anti-skid capacity, increasing effective stress, and ensuring sufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

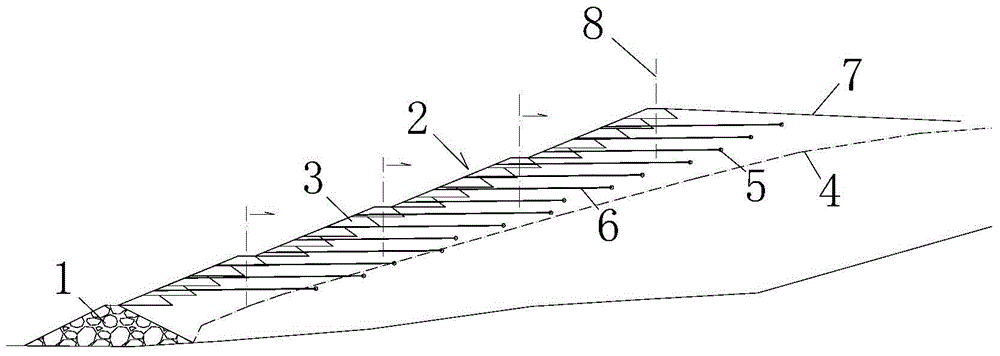

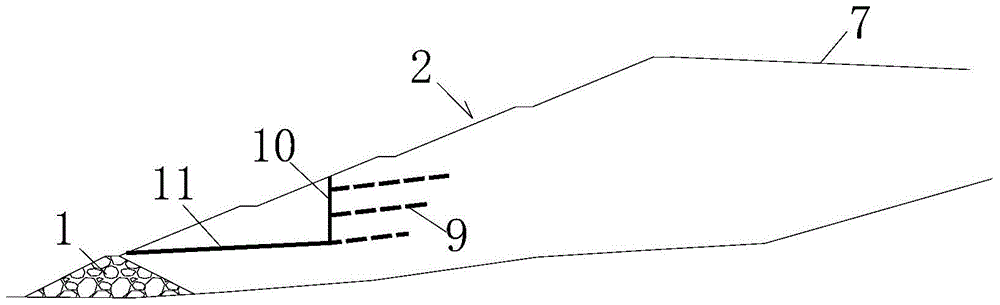

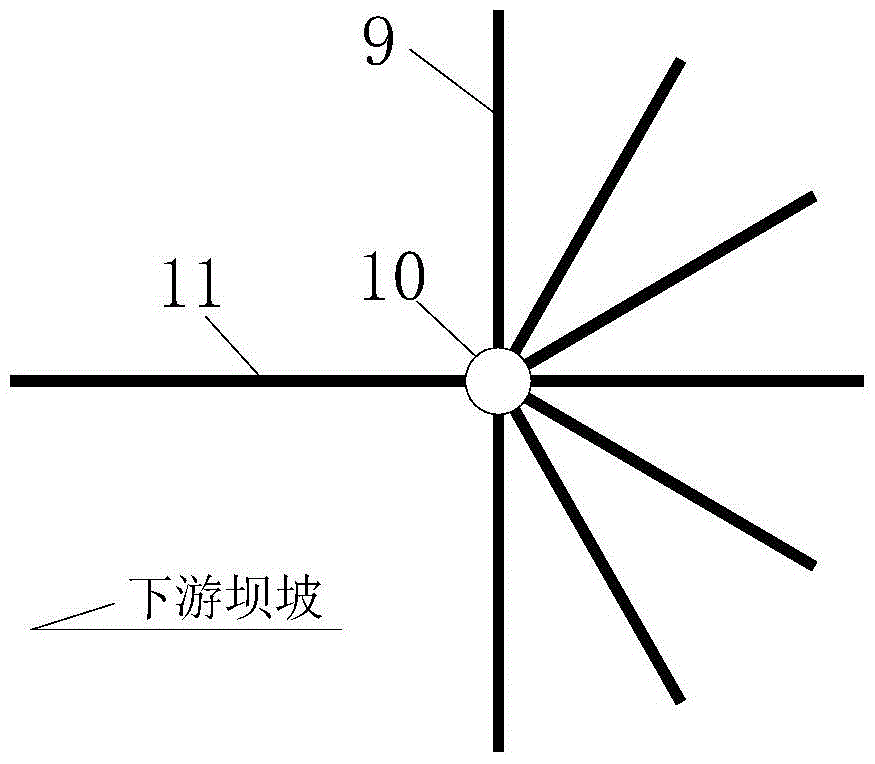

[0034] a kind of like Figure 4 The upstream tailings pond of the present invention is shown, the upstream tailings pond includes an initial dam 1 and an accumulation dam 2 upstream of the initial dam 1, the accumulation dam 2 is provided with the reverse seepage drainage system of the present invention, the reverse The seepage drainage system is arranged in the accumulation dam 2 near the initial dam 1 at the bottom of the tailings pond, and the accumulation dam 2 area where the reverse seepage drainage system is located is set as a supporting prism to support the tailings pond after fully draining seepage. The upstream tailings dam is a key part affecting the stability of the tailings pond in the accumulation dam 2 area close to the initial dam 1. In this embodiment, under the premise of setting a reverse seepage drainage system, the tailings accumulation body in the lower part of this area is fully Drainage forms a supporting prism, which greatly improves the stability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com