Tubular microporous tailing damming method

A technology of tailings and micropores, which is applied in the direction of filling, etc., can solve the problems of dry beach length and safety superhigh that are difficult to meet the requirements, many safety hazards, and unfavorable environmental protection, etc., to achieve good drainage effect, safe superhigh, and separation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

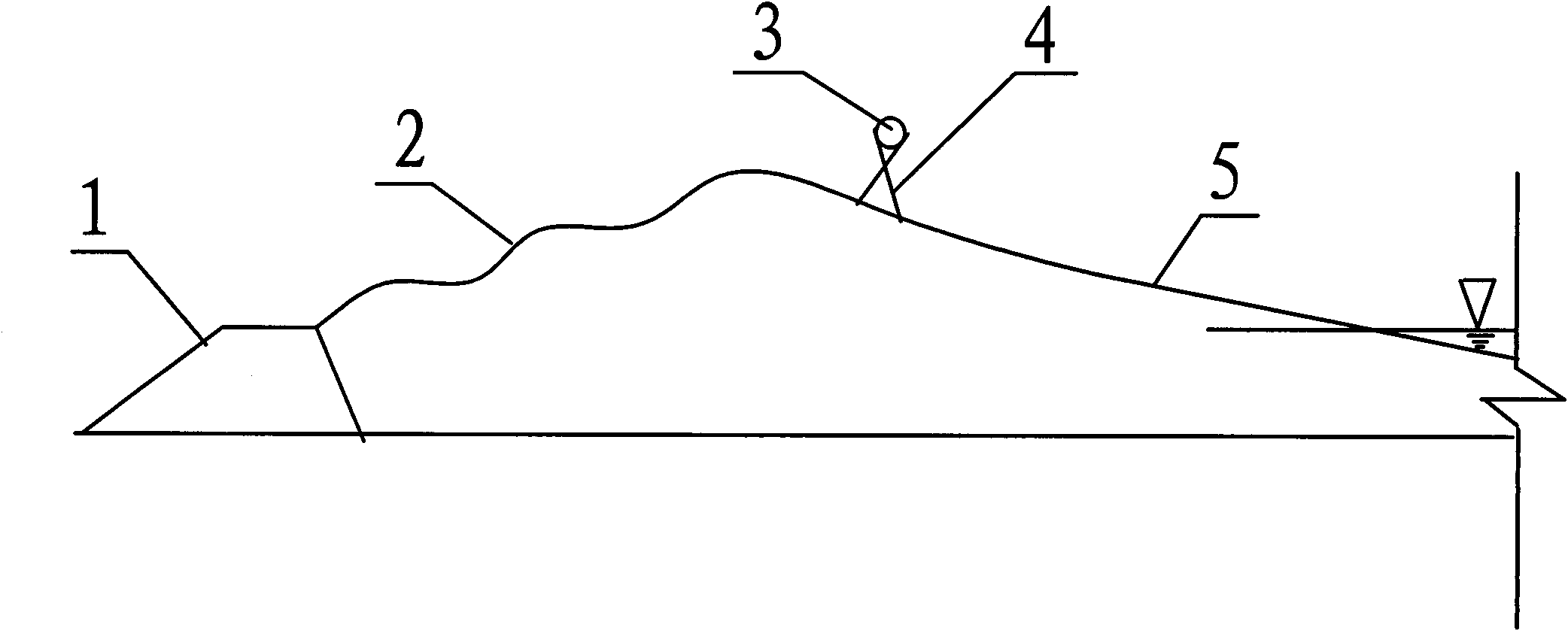

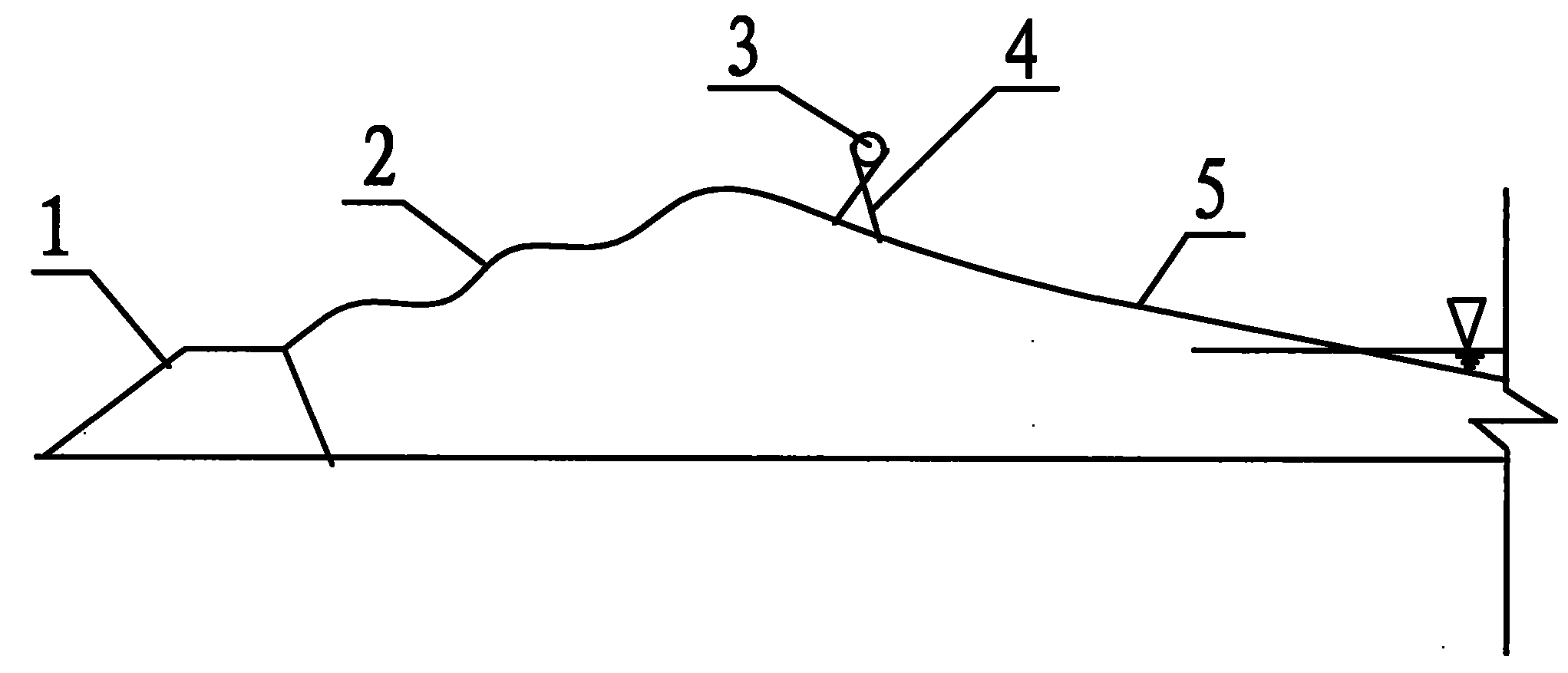

[0021] A method for building a tubular microporous tailings dam, comprising the following steps:

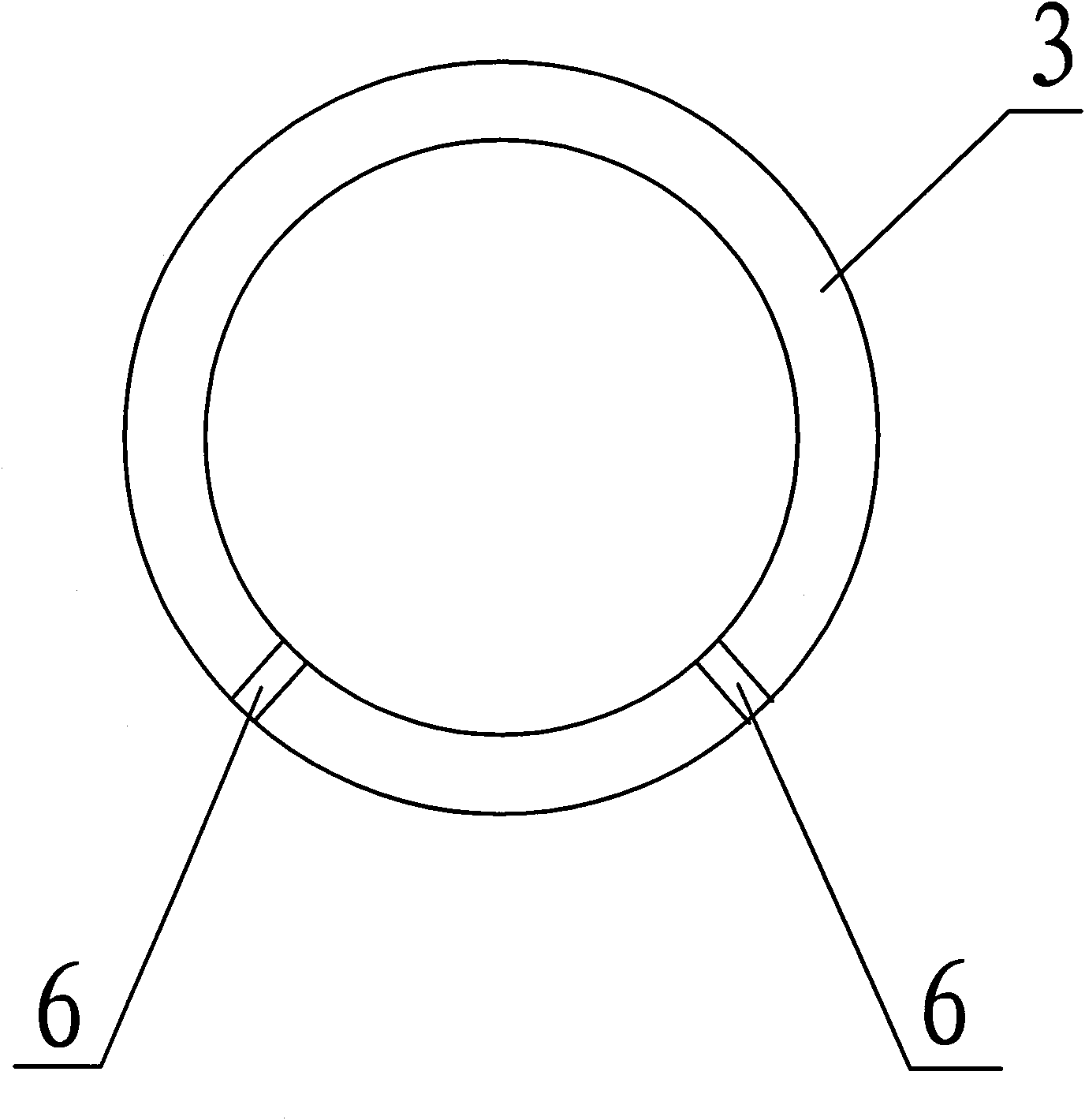

[0022] (1) Make the ore drawing pipe 3: the ore drawing pipe 3 adopts a medium and small diameter pipe, and the ore drawing holes 6 that are evenly arranged are drilled intermittently in the opposite direction under the ore drawing pipe 3;

[0023] (2) Install the ore-drawing pipe support 4: the ore-drawing pipe support 4 is arranged on the dry beach 5 in the storehouse, and the ore-drawing pipe support 4 is installed and fixed on the dry beach 5 in the storehouse with a set distance from the top of the sub-dam 2;

[0024] (3) Install the ore-drawing pipe 3: install and fix the prepared ore-drawing pipe 3 on the ore-drawing pipe support 4;

[0025] (4) Adjust the ore-drawing hole 6: open and block the ore-drawing hole 6 as required during ore drawing;

[0026] (5) Dam building: while the ore is drawn, the tailings are deposited into a sub-dam 2 with higher strength connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com