Method for reducing wetted surface of dam slope of mud-containing interlayer tailing dam

A tailings dam and wetting surface technology, which is applied in dams, dikes, sea area engineering, etc., can solve the problems of vertical infiltration of water and other problems, and achieve the effect of reducing the wetting line and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0024] The invention provides a method for reducing the wetting surface of the dam slope of a mud-containing interlayer tailings dam, comprising the following steps:

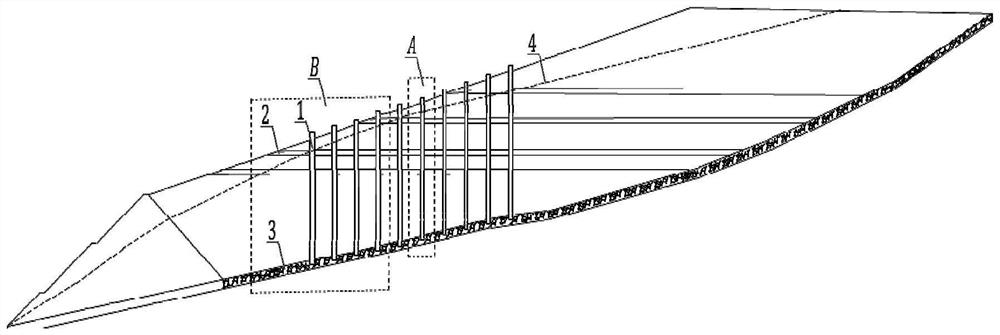

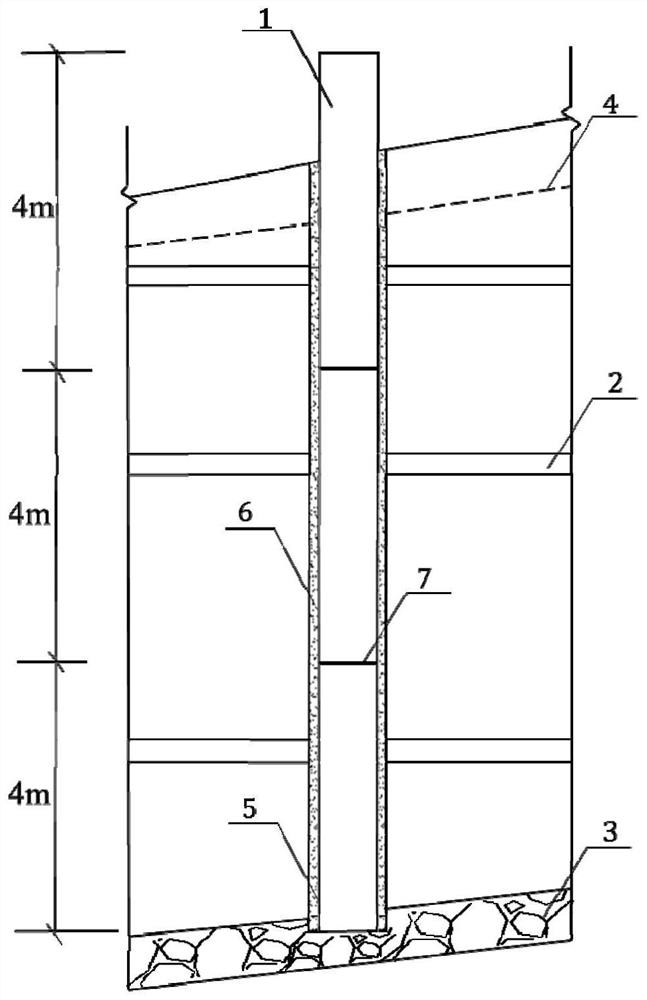

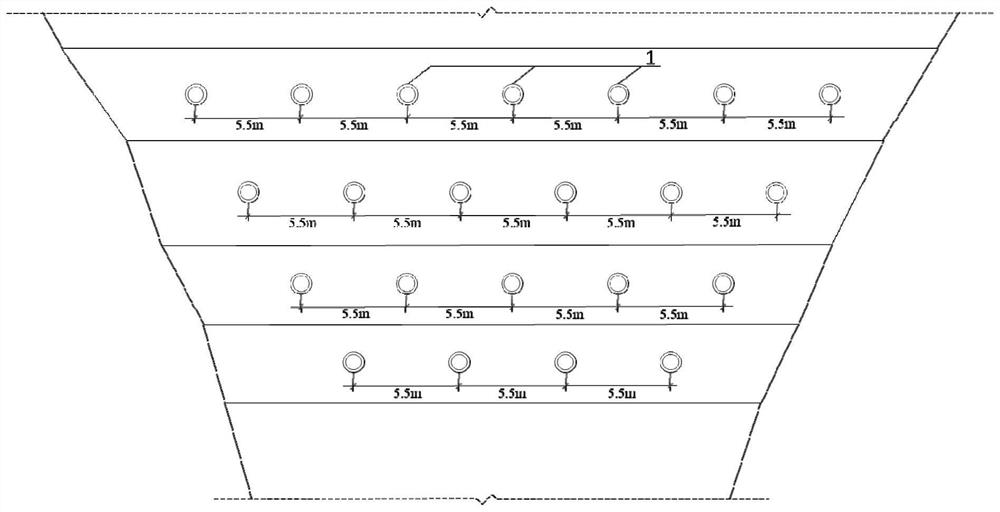

[0025] Step 1, such as figure 1 As shown, according to the length of the dam body, the area of the reservoir and the distribution of the mud interlayer 2 with a thickness of 1 m in the dam body, the position of the drilling hole is determined according to the elevation of the infiltration line 4 and the overflow position, and the drilling is carried out in the vertical direction on the dam slope. hole, the hole diameter of the drilled hole is The drilling depth extends to the drainage lens body 3 at the bottom of the dam body, and connects with the drainage lens body 3 to realize natural drainage. The drilling arrangement is based on the shortest distance from the wetting lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com