Full tailing slurry filling mold bag solidified body dam stacking process

A technology of solidified body and mold bag, which is applied in filling, foundation structure engineering, soil protection, etc. It can solve the problems of low strength index, high dam soaking line, and easy displacement, etc., and achieves simple and convenient dam construction process. The effect of high stability and high safety of the dam body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

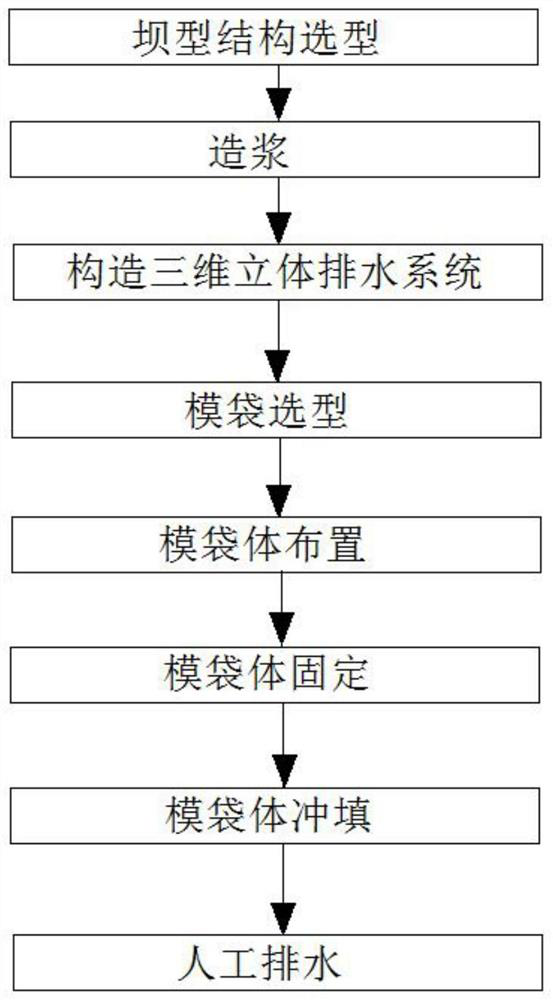

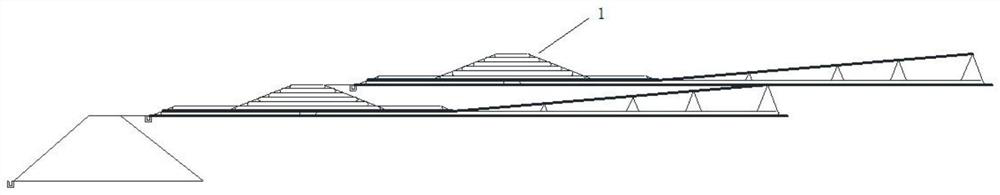

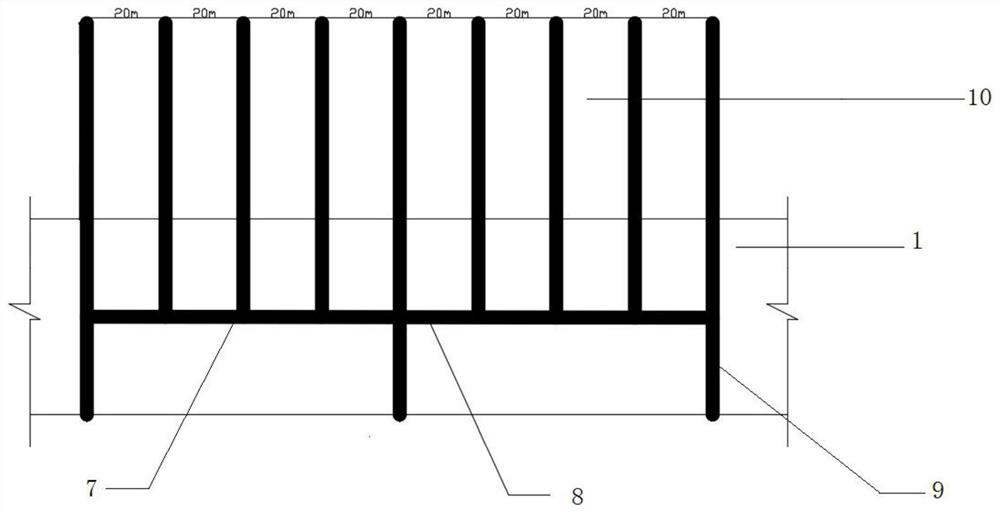

[0041] Such as figure 1 As shown, this embodiment provides a full tailings slurry filling mold bag solidification body dam building process, through the selection of dam structure, pulping, construction of three-dimensional drainage system, mold bag selection, mold bag body layout, mold bag Body fixing, mold bag body flushing and filling, artificial drainage and other processes to form a mold bag dam body 1, such as image 3 shown. The specific dam stacking process is as follows:

[0042] Step 1: Dam type selection In order to meet the safety needs of the tailings pond, the molded bag solidified body, that is, the molded bag dam body 1. The dam type structure includes stepped trapezoidal dam, stepped italic trapezoidal dam, stepped parallelogram beveled dam, stepped Add back pressure platform dam and other dam types; the appearance size of the final molded bag dam body 1 should be controlled at the crest width of 3-100m, height of 3-20m, and internal and external slope ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com