Framework type seepage drainage system and method

A frame-type, frame-based technology, applied in dikes, climate change adaptation, coastline protection, etc., can solve problems such as difficulty in discharging tailings water, and achieve the effects of ensuring safety, preventing environmental pollution, and avoiding dam instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

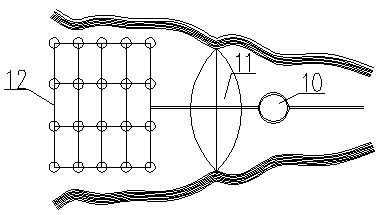

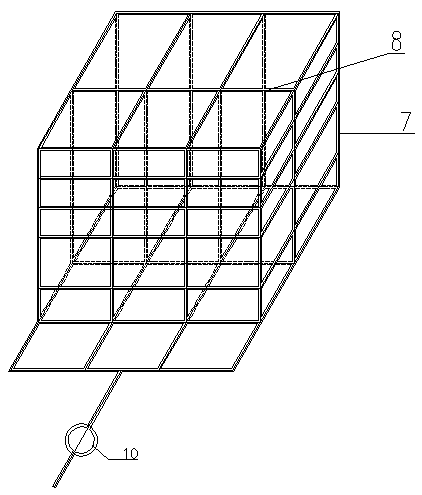

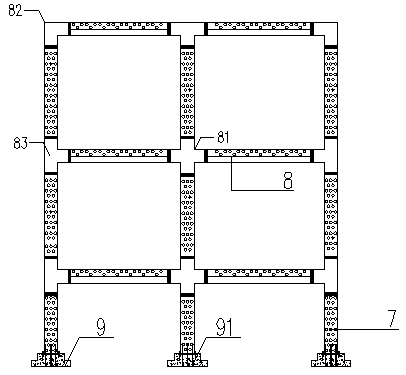

[0034] As shown in the figure, a concrete water collection well 10 is provided under the tailings dam 11, and a frame drainage body 12 is arranged in the tailings pond. The frame drainage body 12 is composed of a vertical column type drainage pipe 7 and a horizontal The beam-type drainage pipes 8 are connected by connectors, the floor height of the beam-type drainage pipes is 3-5m, and the distance between adjacent column-type drainage pipes 7 is 50-100m.

[0035] The node connection between the column type drainage pipe 7 and the horizontal beam type drainage pipe 8 can be orthogonal (such as image 3 ), can also be skewed (such as Figure 4 ), the beam-type seepage drainage pipe 8 is arranged inclined downward, and the inclination angle is between 45°-90°. To facilitate the discharge of water in the dam.

[0036] Such as Figure 5-7 As shown, the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com