Tailings reverse filter material, preparation method and application, seepage structure and application of reverse filter material

A technology of reverse filter material and tailings, which is applied in the field of tailings treatment, can solve problems such as high infiltration line of tailings dams and difficult drainage, and achieve the effects of safety and stability, prevention of silting, and improvement of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

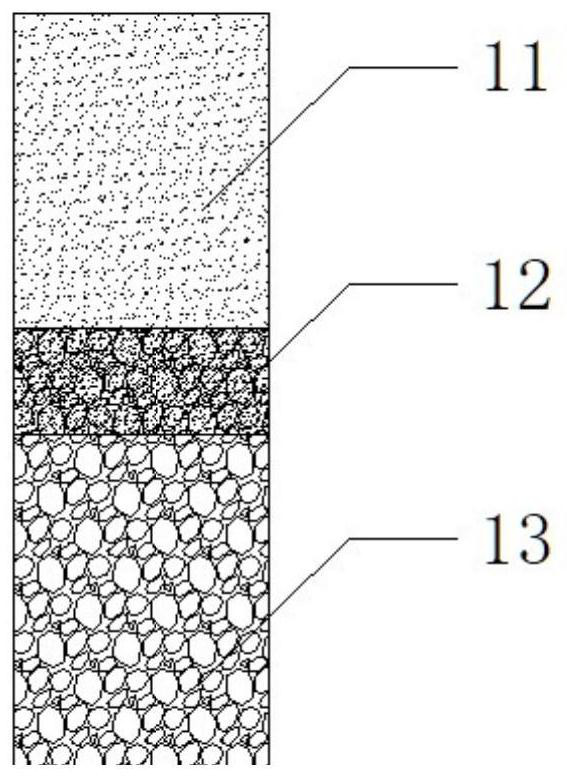

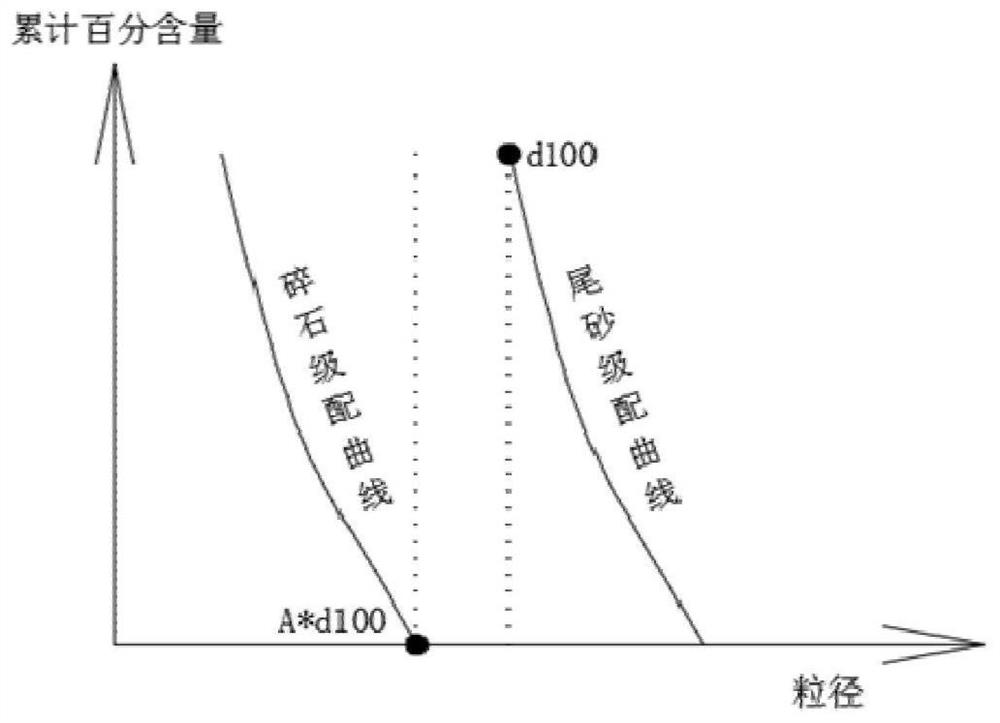

[0043] Wherein the minimum particle size of crushed stone df=A×d100, A is the particle size adjustment coefficient, 1≤A≤2.

Embodiment 2

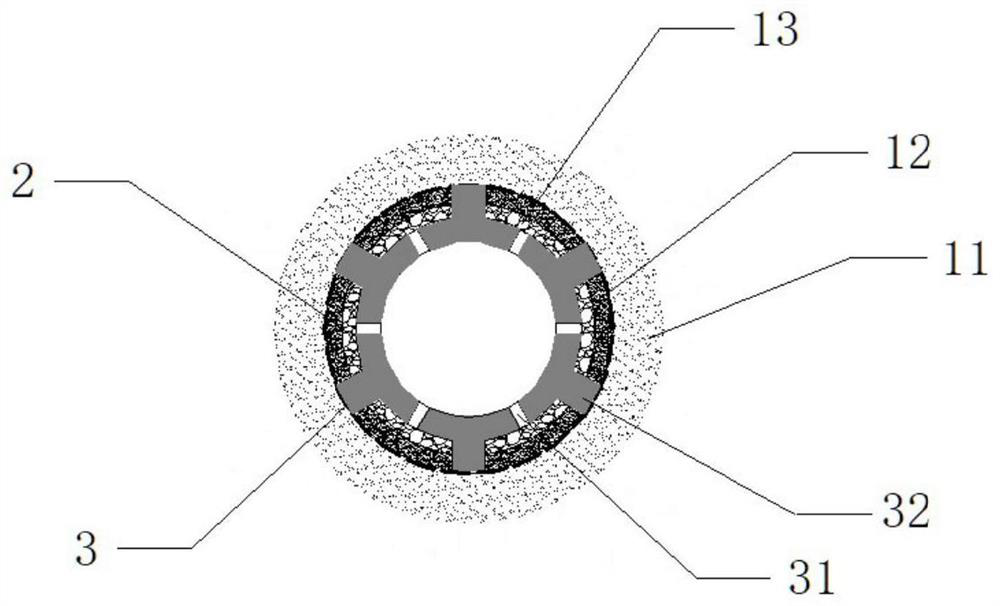

[0054] A drain hole 31 is provided on the wall of the seepage pipe 3.

[0057] In a typical but non-limiting embodiment of the present invention, the drainage pipe 3 is evenly distributed with partitions 32 in the circumferential direction.

[0058] The screen 2 includes a metal mesh.

[0059] In a typical but non-limiting embodiment of the present invention, the filter screen 2 is a metal mesh. Metal mesh has a good

Embodiment 3

[0062] The present embodiment provides a kind of tailings reverse filter material and the application of the reverse filter material seepage structure in the tailings dam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com