Window-type drainage well and construction method thereof

A drainage well and window-type technology, applied to drainage structures, waterway systems, water supply devices, etc., can solve the problems of poor installation, easy slurry leakage, laborious transportation, etc., and achieve the effect of easy installation, flexible use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

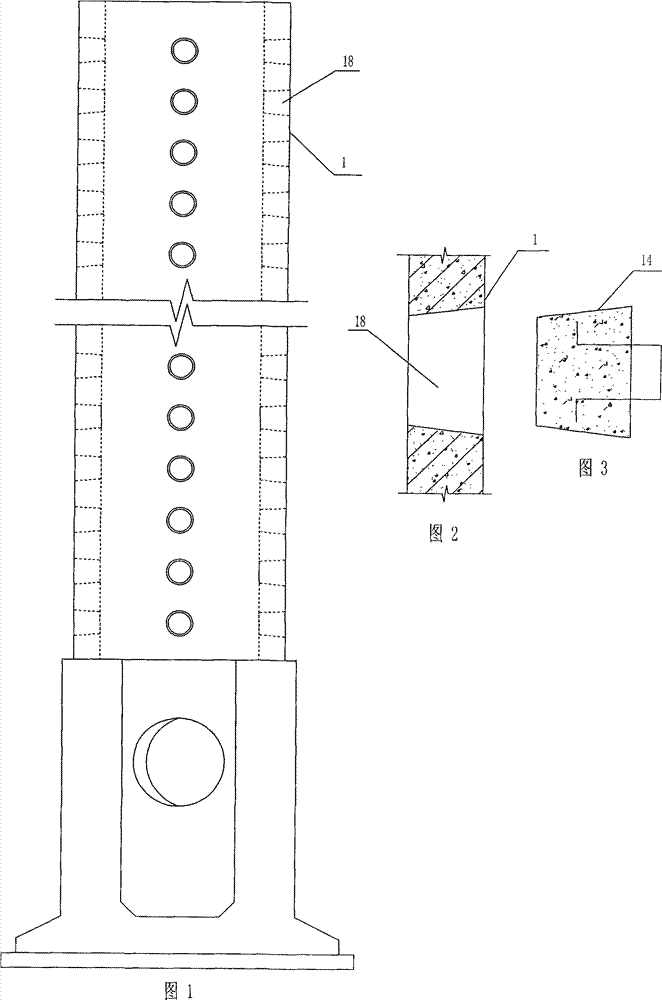

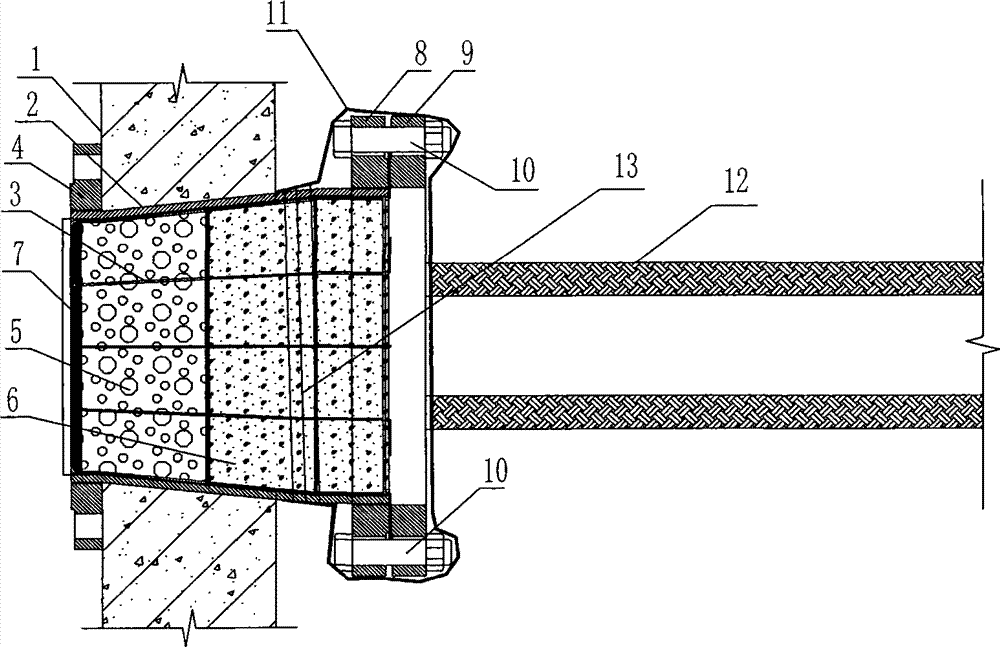

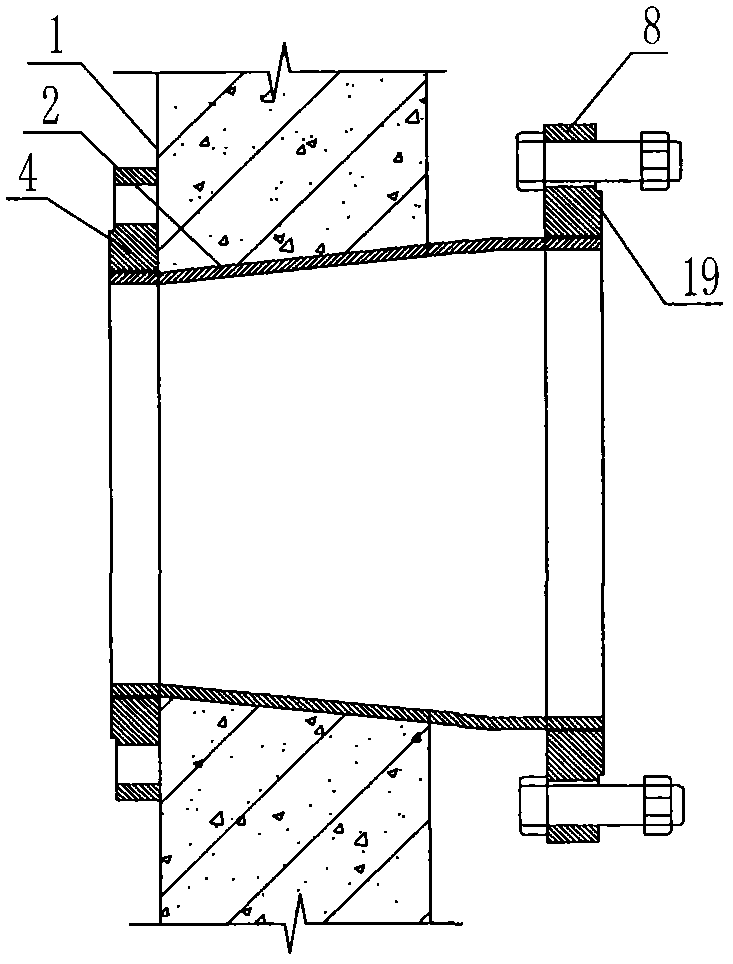

[0039] Example 1 as Figure 4 to Figure 12As shown, the window type drainage well in embodiment 1 is used as a seepage collection well, including a well shaft and a well seat, the well shaft is located on the top of the well seat, the well shaft is provided with a well wall 1, and the well wall 1 is provided with a drainage window 18, and the drainage window 18 The inner wall is in the shape of a truncated cone, and the inner diameter of the truncated circular inner wall is small and the outer diameter is large. Drainage window 18 is provided with different-diameter pipe 2, and the outer wall of different-diameter pipe 2 is compatible with the inner wall of drainage window 18; The inner wall of the reducing pipe 2 is matched, the filter device is filled in the cage 3, and the outside of the reducing pipe 2 (the right end of the present embodiment) is provided with a first flange 8. The outer side of the cage 3 (the right end of the cage 3 in this embodiment) is provided with ...

Embodiment 2

[0045] Example 2 as Figure 13 As shown, the first flange 8 of a window-type drainage well in Embodiment 2 is fixed with a blind flange 21 by bolts. The blind flange 21 is a flat flange without water holes, and the blind flange is used to block the drainage window. Other structures of embodiment 2 are the same as embodiment 1.

[0046] The construction and use steps of the window type drainage well in Embodiment 2 of the present invention are as follows:

[0047] (1) Excavation of the well base: Excavate to the design depth, the buried depth of the well base is generally not less than 2 / 3 of the height of the well base, and the bearing capacity of the foundation is generally not less than 200kPa.

[0048] (2) Manufacture of well base: supporting formwork, placing steel bars, pouring concrete, and curing.

[0049] (3) Manufacture of the wellbore: support the formwork, place steel bars, pour concrete, and maintain. A different-diameter pipe is placed at the position of the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bearing capacity of foundation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com