Damming method of tailing subdam

A tailings accumulation dam and tailings technology, applied in the direction of filling, etc., can solve the problems of reducing the soaking line, uneconomical, poor seepage, etc., and achieve the effect of simple and fast construction, reducing the soaking line, and beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

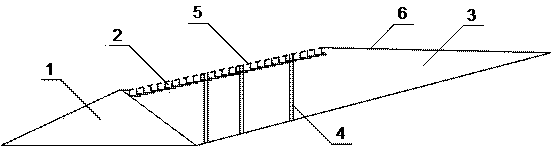

[0058] The selected tailings pool is a nearly north-south valley, which is high in the north and low in the south as a whole, surrounded by mountains on the east, west and north sides. The elevation of the bottom of the valley is between 2380m and 2560m. Branch ditch. The cross section of the valley is V-shaped. The slopes of the mountains on both sides of the valley are between 30° and 50°. In the reservoir area, gravel soil is distributed only in valleys and local gentle slopes. The thickness of the layer in the valleys is relatively large, and the thickness of the covering layer on the slopes is small. Many bedrocks are exposed in the entire reservoir area. Faults or fault zones are found. The tailings dam is built by the upstream method. The slope ratio of the outer dam of the dam is 1:4.5, and the slope ratio of the inner dam is 1:1.3. The total dam height is 150m, the initial dam height is 90.0m, and the permeability coefficient is 0.01m / s; the permeability coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com