A method for improving in-service tailings pond capacity and a device thereof

A technology of tailings pond and capacity, which is applied in the fields of mine mining and mine tailings dam stacking, can solve the problems of huge construction, transportation costs, high investment costs of tailings ponds, and increased tailings transportation distance, and achieves a simple construction process. Efficient, prolong the service life, increase the effect of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

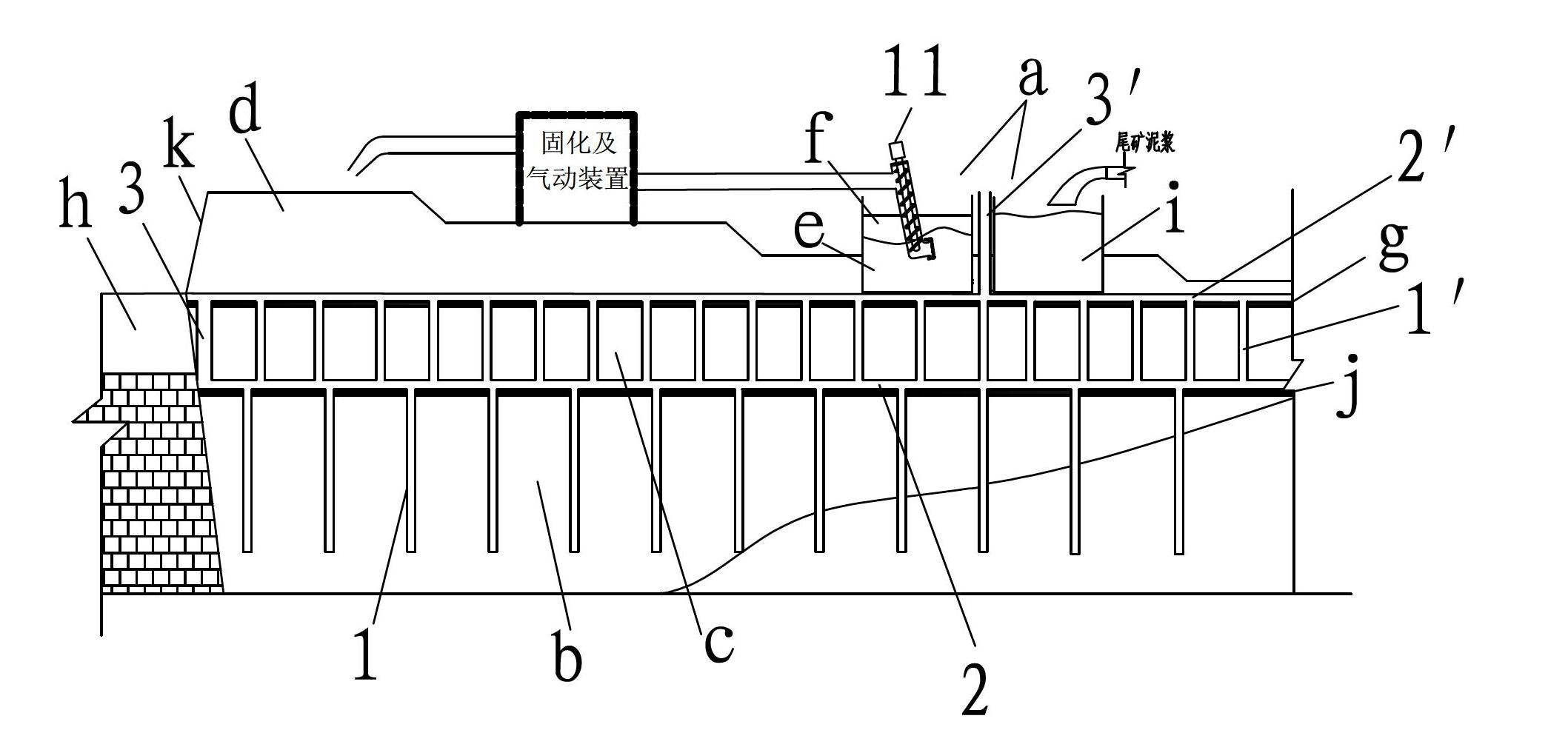

[0063] A bauxite tailings pond has reached the designed storage capacity, with a top surface area of 100 hectares, a dam height of 30m, a dam bottom width of 75m, a dam crest width of 15m, and a slope of 45. , the daily discharge of tailings pulp is 15,000 m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0064] The first step is to analyze the existing tailings pond, and divide the tailings pond into two areas according to the original tailings mud bearing capacity, area Ⅰ and Ⅱ, and area Ⅰ is characterized by large tailings mud particle size, good deposition effect, and good bearing capacity. The area with slightly stronger capacity is about 20 hectares; area II is the area with insufficient carrying capacity and the surface layer is like thin mud, about 80 hectares. Area Ⅰ has a slightly stronger load-bearing capacity. Firstly, a layer of straw woven sheet is properly paved as the base layer of the workin...

Embodiment 2

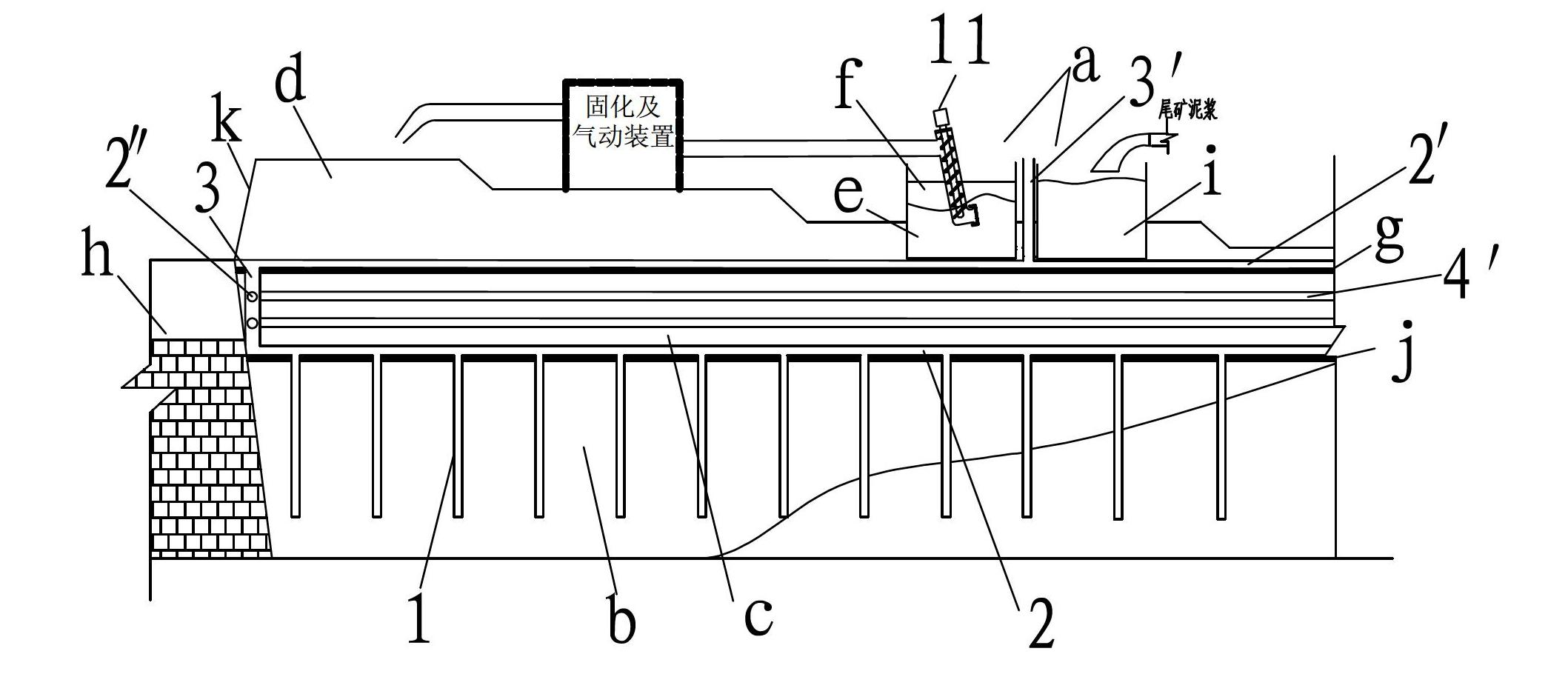

[0069] A copper mine tailings pond has reached the designed storage capacity, with a top surface area of 60 hectares, a dam height of 30m, a dam bottom width of 75m, a dam crest width of 15m, and a slope of 45°. , the daily discharge of tailings mud is 0.9 million m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0070] ① Analyze the existing tailings pond, and divide the tailings pond into two areas according to the carrying capacity of tailings mud, area I and II, and area I is the area with large tailings mud particle size, good deposition effect and slightly stronger carrying capacity About 10 hectares; Area II is an area with insufficient carrying capacity and a muddy surface, about 50 hectares. In area Ⅰ, the bearing capacity is slightly stronger, and the geotextile is properly paved as the base layer of the working cushion; in area Ⅱ, a layer of geotextile is firstly paved as the surface support, and ...

Embodiment 3

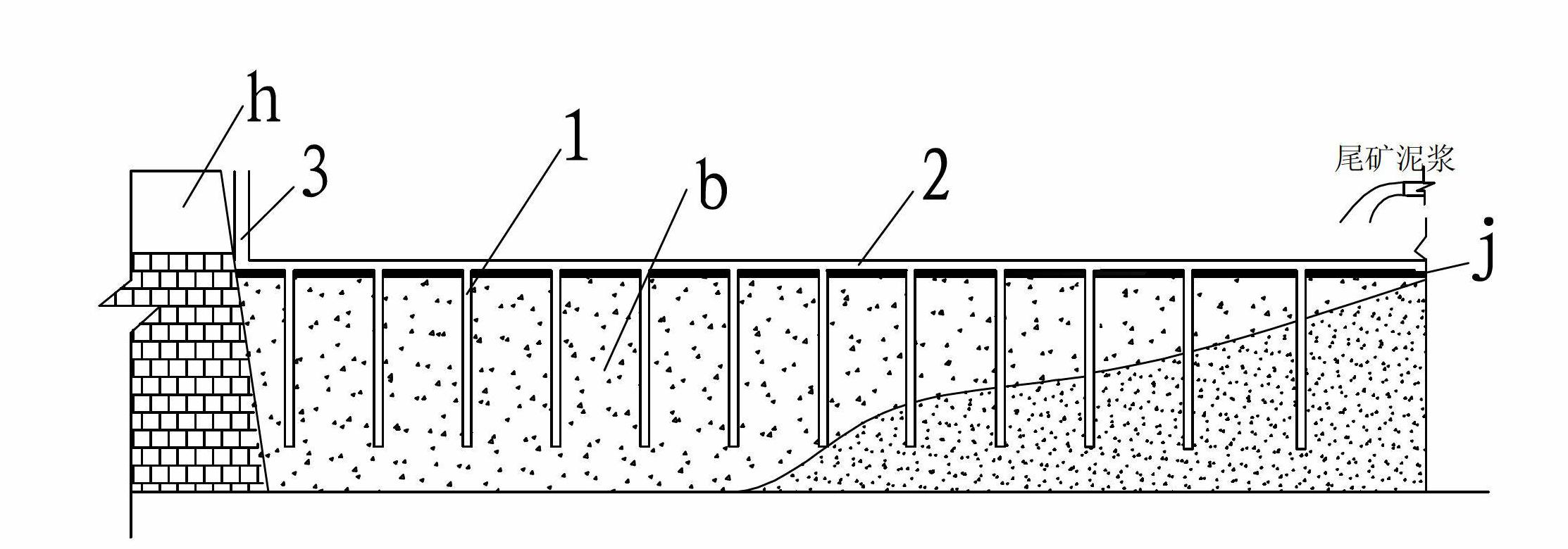

[0075] An iron ore tailings pond in a certain mine has reached the designed storage capacity, with a top surface area of 150 hectares, a safety dam height of 48m, a dam bottom width of 120m, and a dam crest width of 10m. The daily discharge of tailings slurry is 30,000 m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0076] ① Analyze the existing tailings pool, and divide the tailings pool into three areas according to the carrying capacity of tailings mud, area Ⅰ, Ⅱ, and Ⅲ, and area Ⅰ is the area on the boundary of the tailings pool with sufficient carrying capacity, about 5 hectares; area Ⅱ is an area with large tailings mud particle size, good sedimentation effect, and slightly stronger bearing capacity, about 50 hectares; area Ⅲ is an area with no bearing capacity and a thin muddy surface layer, which must be treated properly to have a follow-up The construction capacity is about 95 hectares. Area Ⅰ doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com