Chemical siltation resisting drainage device for tailing dam

A technology for chemical fouling and tailings dam, applied in soil protection, excavation, construction, etc., can solve the problems of chemical fouling of non-woven geotextiles, poor seepage drainage effect of tailings dams, and elevated dam body wetting lines, etc. Achieve high efficiency, reduce operational risks, and ensure the effect of normal drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

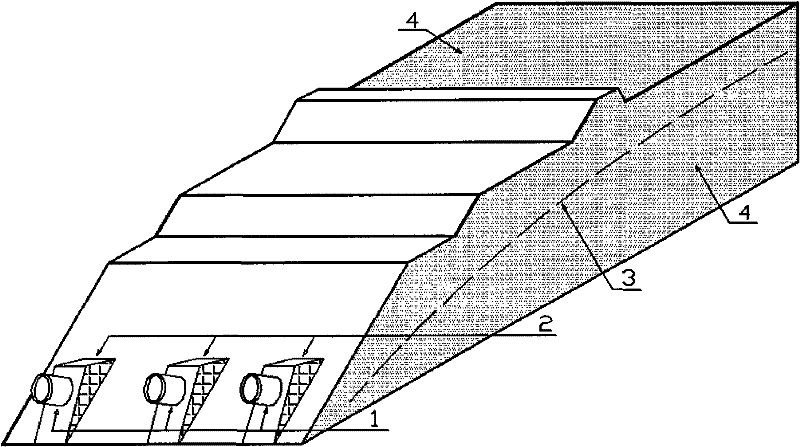

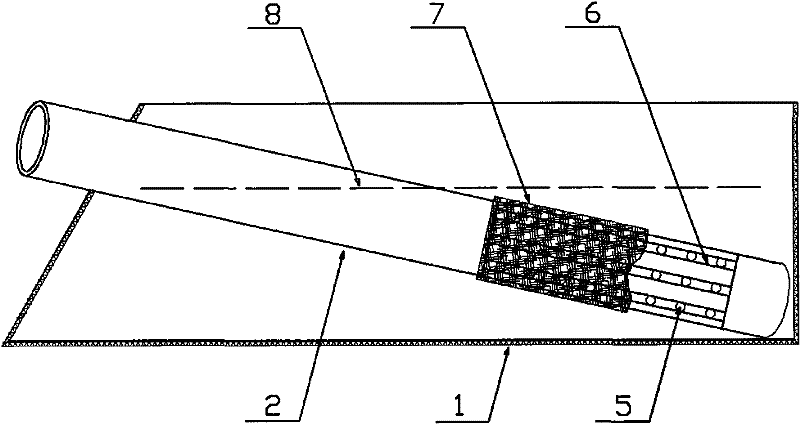

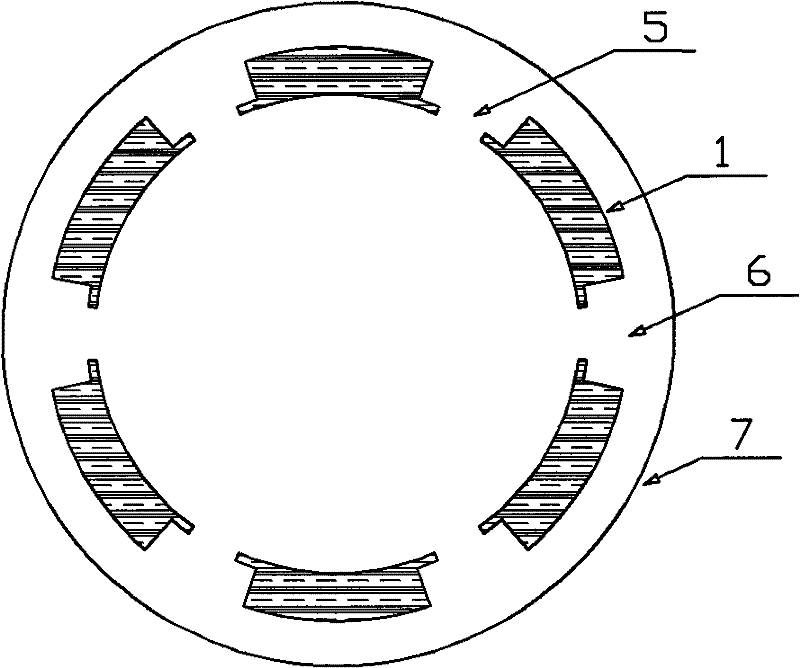

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] according to figure 1 , figure 2 , image 3 It can be seen that the seepage drainage device includes a seepage drainage pipe 1, a seepage tank 6, a water seepage hole 5, a geotextile 7, an anti-silting tank 2, a soaking line 3, an accumulation dam 4, and a water level line 8 of the anti-silting tank. A tailings dam anti-chemical clogging seepage device, its connection relationship and function are:

[0024] A seepage prevention device for preventing chemical silting and seepage of a tailings dam. The seepage discharge pipe 1 is a circular pipe, and a seepage tank 6 is arranged at the end of the pipe, and its function is to ensure that the water flow can be discharged from the dam body in time and smoothly. Simultaneously in seepage groove 6, chisel out circular seepage hole 5, its effect is to allow the water in the dam body to infiltrate in the seepage pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com