Motor terminal portion structure

A terminal part and motor technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of water immersion into the insulating parts, and the generalization of the parts is not ideal, so as to improve the assembly operability, Reliable blocking and reduction of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

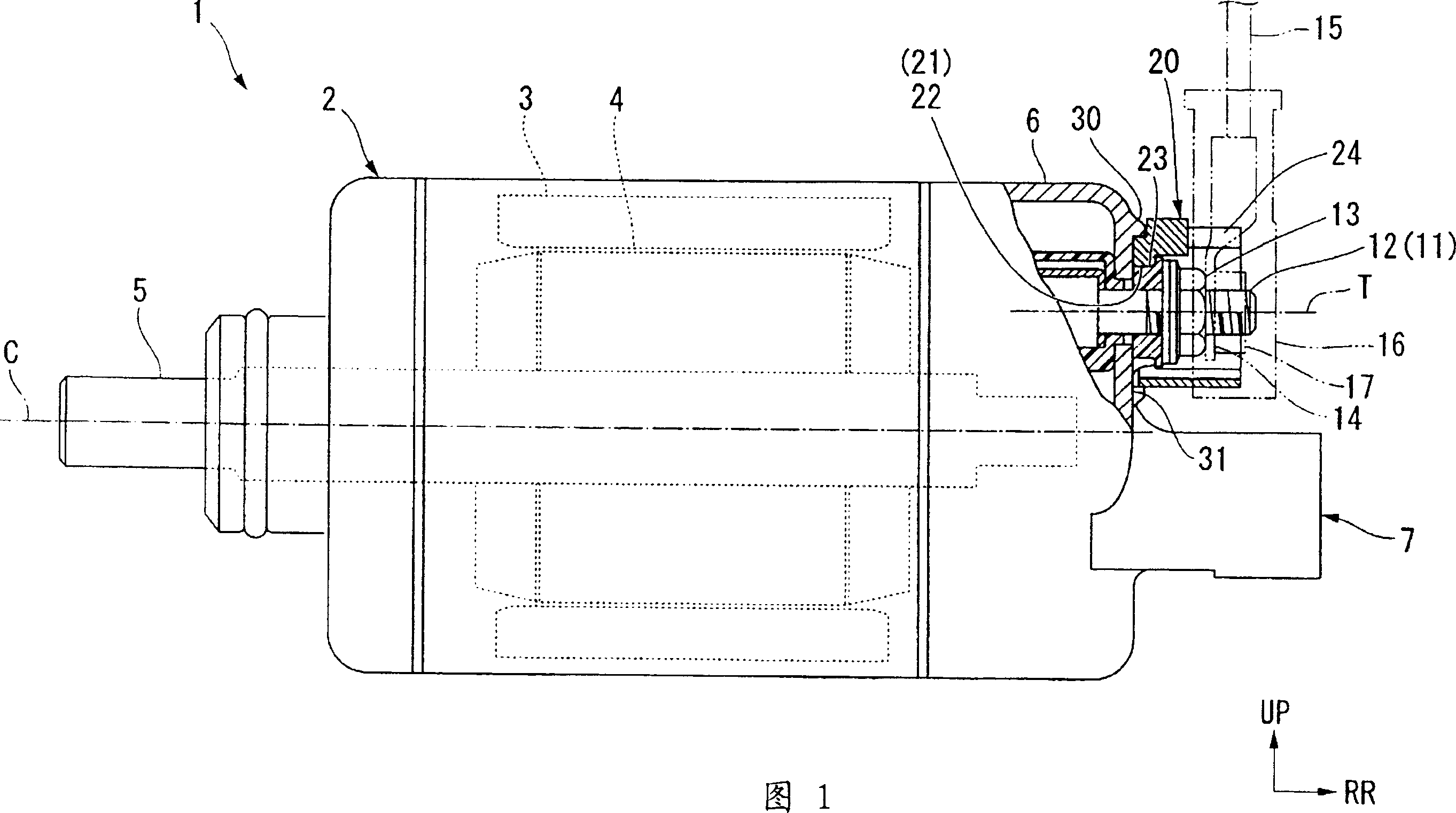

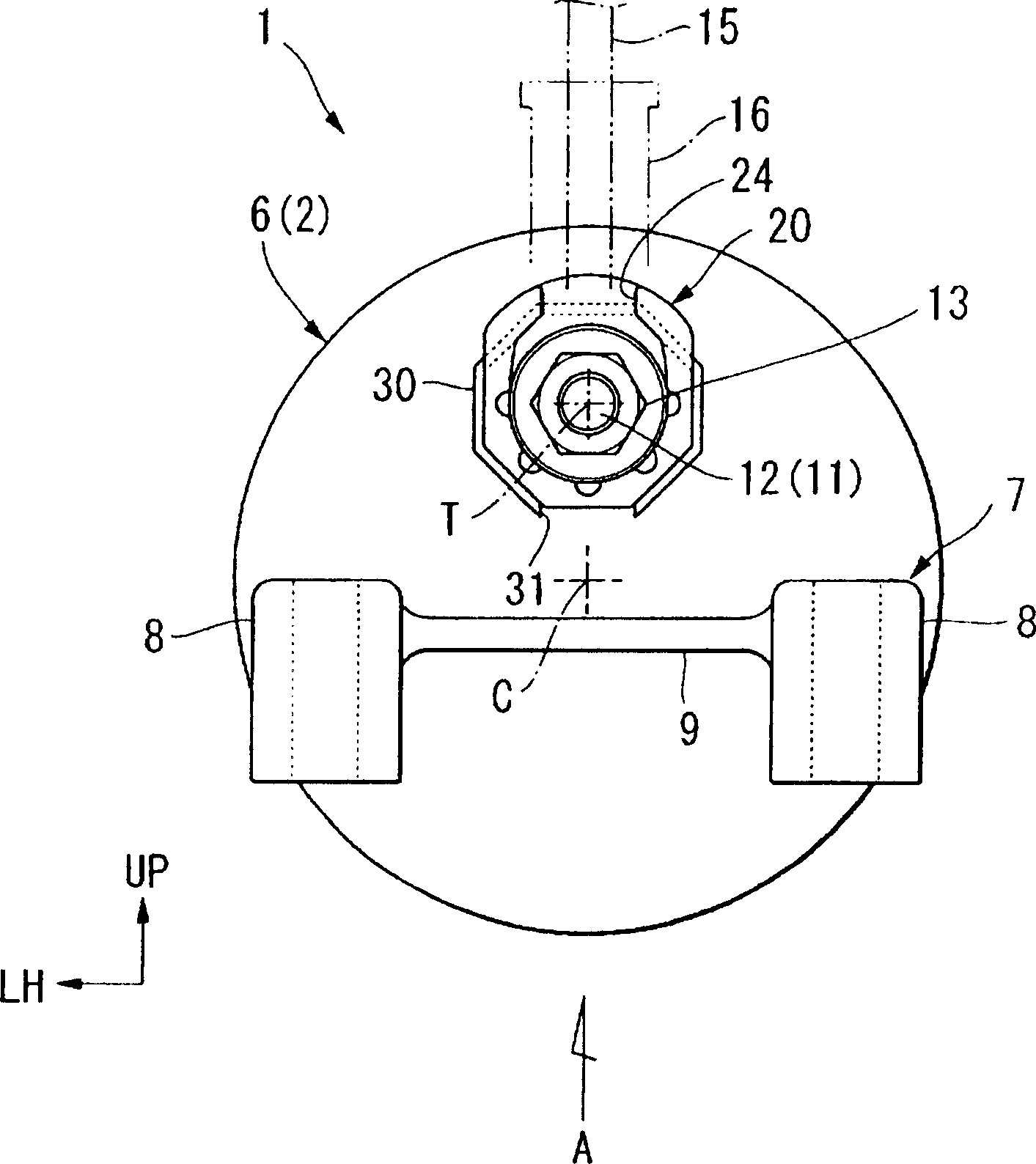

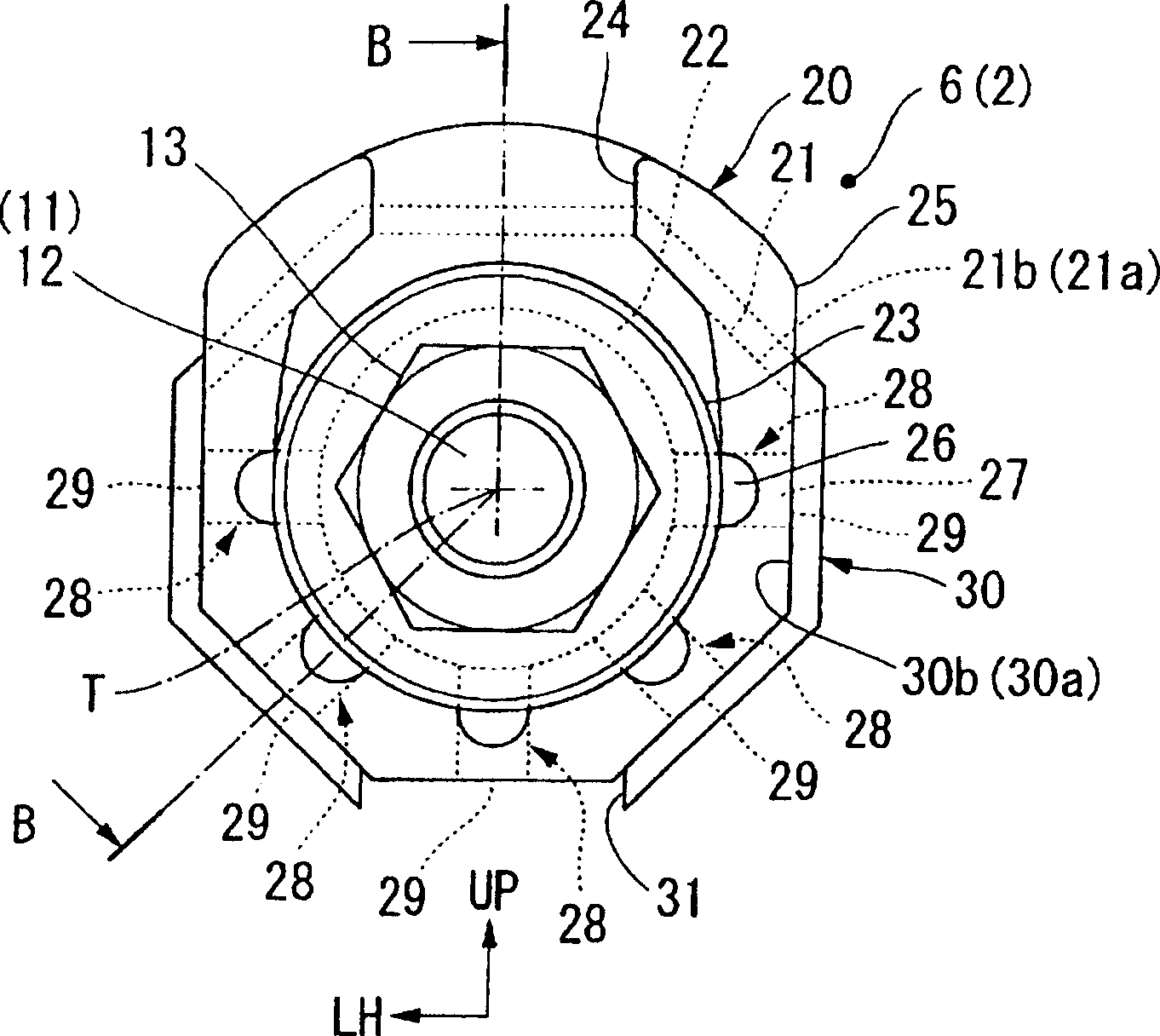

[0033] Embodiments of this invention will be described below with reference to the drawings.

[0034] The motor 1 shown in Figures 1 and 2 is, for example, a starter motor of an automatic two-wheeled vehicle, and has a substantially cylindrical casing 2, a stator 3 is fixed on the outer peripheral side of the casing 2, and a stator 3 is fixed on the inner peripheral side thereof. The rotor 4 is rotatably arranged. The rotor 4 is integrated with a rotating shaft 5 penetrating therethrough, and the rotating shaft 5 is rotatably supported by the casing 2 .

[0035] Then, the rotor 4 and the rotating shaft 5 are integrally driven to rotate by the electric power supplied from the vehicle-mounted battery to the motor 1 . Such a motor 1 is mounted on a vehicle with its rotation axes C substantially parallel. In the following description, the arrow RR in the figure indicates the rear along the direction (axial direction) of the above-mentioned rotation axis C of the motor 1 assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com