LED chip surface fluorescent powder layer coating method

A technology of LED chip and coating method, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven wavelength conversion, light and color shift of LED components, and inability to commercialize mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

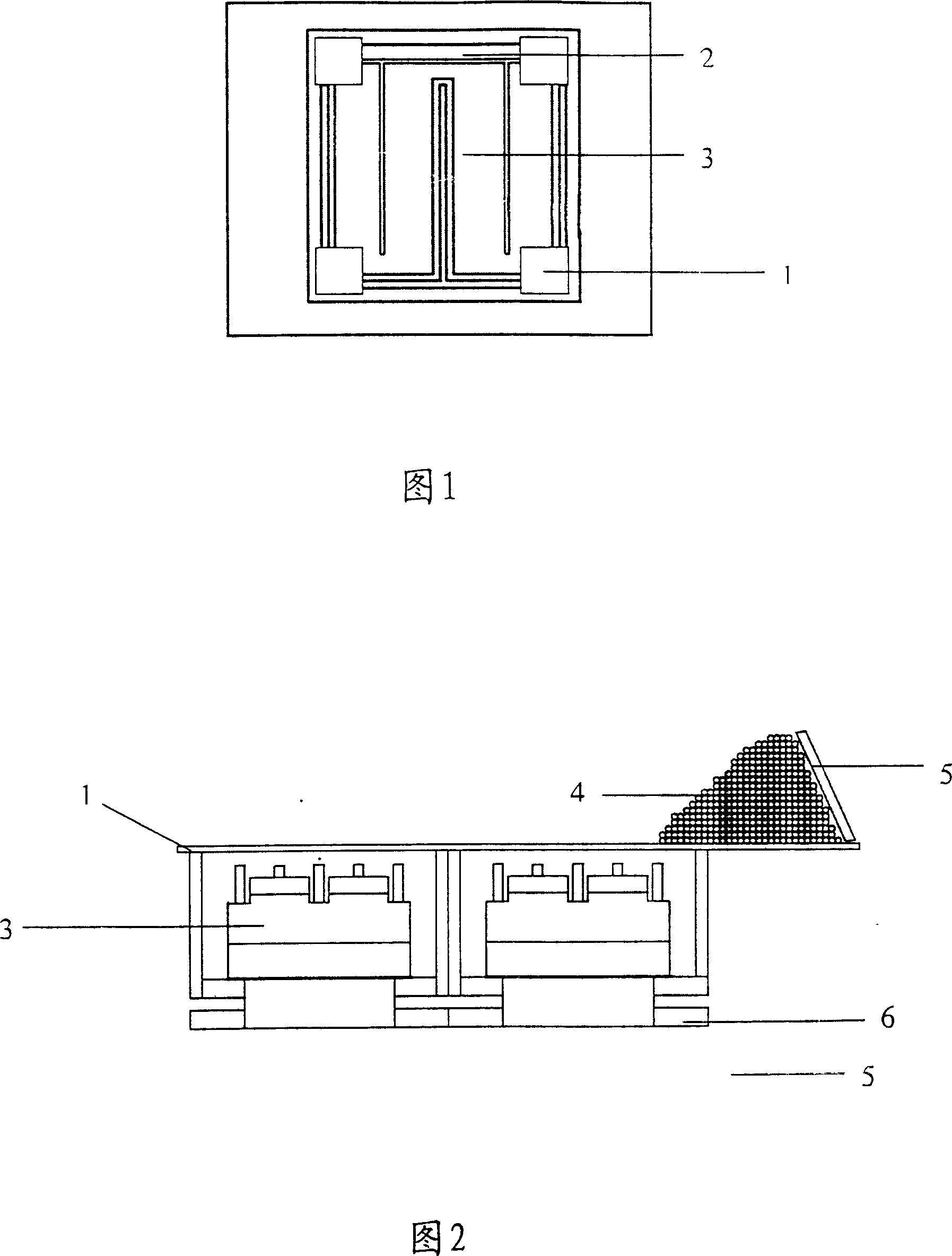

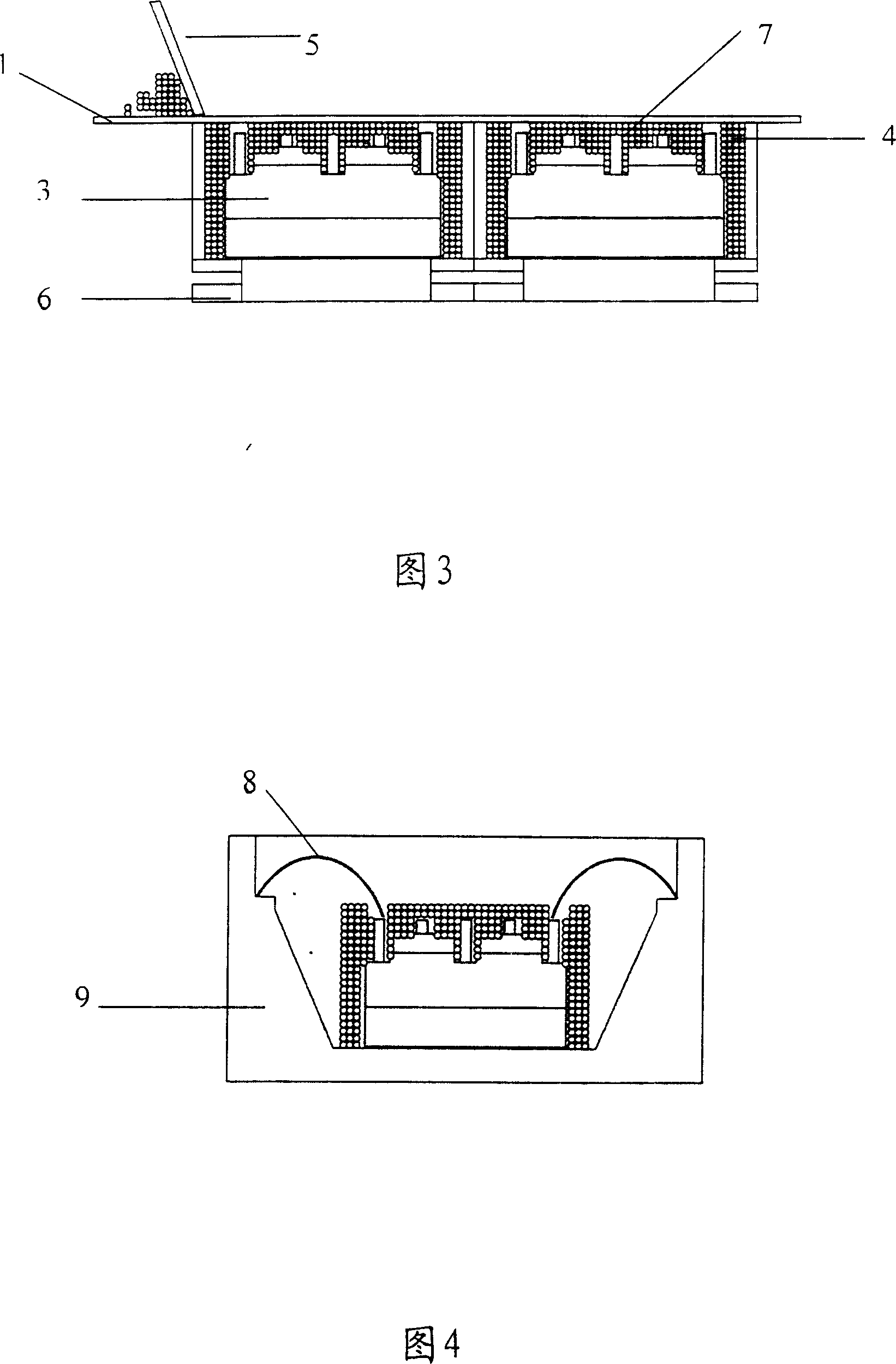

[0026] Implementation method 1: as shown in Figure 2 to Figure 4, first separate the divided LED chips 3 (LED chips can be binary materials such as GaN or quaternary materials such as AlGaNP and other various LED chip materials) one by one. Put it on the special fixture 6 or on the metal foil or other carrier or tool. The metal foil can be metal or alloy such as gold, silver, copper and aluminum. Place the screen plate 1 on the jig and open it, then place the pre-mixed fluorescent glue on the plate, use the scraper 5 to push the fluorescent glue back and forth with an appropriate force, so that the fluorescent glue is pushed into the underside of the screen plate. In the gap, fill the space under the fixture, LED chip and screen; as shown in Figure 3, because there is a shielding area on the screen, a vacancy 7 will be formed under the shielding area that is not filled with fluorescent glue , the vacancies can expose the electrodes on the LED chip and not be covered by fluores...

Embodiment approach 2

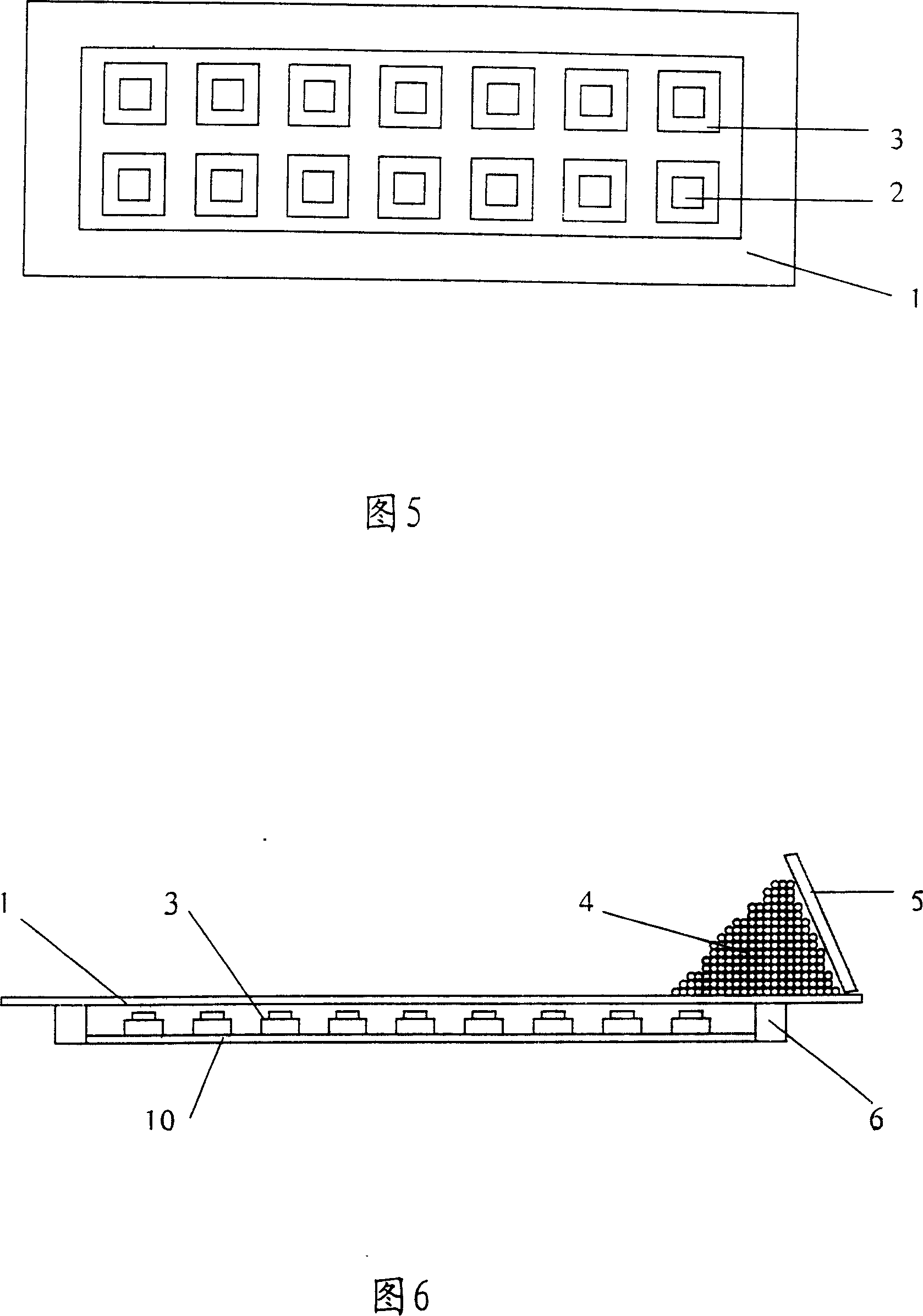

[0027] Implementation method 2: As shown in Fig. 5 to Fig. 8, the shielding area 2 is prepared in advance on the screen plate 1 in Fig. 5 . First fix the LED chip 3 on the copper foil 10 and arrange it well, place the screen plate 1 on the jig 6 and open it, then place the phosphor glue pre-mixed with phosphor powder on the plate, and use the scraper 5 with an appropriate force Push the fluorescent glue back and forth, so that the fluorescent glue is pushed into the gap under the screen, and fills the space under the fixture, LED chips and the screen, as shown in Figure 7, because there is a shielding area on the screen If it exists, a vacancy 7 will be formed under the shielding area and is not filled by the fluorescent glue. The vacancy can expose the electrodes on the LED chip and not be covered by the fluorescent glue. Then use a laser (Laser) or a diamond cutter to cut the LED chips together with fluorescent glue and copper foil into individual pieces, as shown in Figure ...

Embodiment approach 3

[0028] Implementation method three: as shown in Figure 9 to Figure 12, the shielding area 2 is pre-made on the screen plate 1 in Figure 9, and then as shown in Figure 10, the LED chip 11 that has been pre-finished with surface groove treatment is fixed on the clamp Place the screen plate 1 on the jig 6 and open it on the jig 6, then put the fluorescent glue pre-mixed with the phosphor powder on the plate, and push the fluorescent glue back and forth with a proper force with the scraper 5, so that the fluorescent glue is pushed Squeeze into the gap below the screen, and fill the space under the fixture, LED chip and screen, as shown in Figure 11, because there is a shielding area on the screen, a vacancy will be formed under the shielding area 7 Filled with fluorescent glue, the vacancies can expose the electrodes on the LED chip without being covered by fluorescent glue. Then use a laser or a diamond cutter to cut the LED chips together with fluorescent glue and copper foil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com