Arc welding-brazing method for titanium-aluminum dissimilar alloy TIG (tungsten inert gas) arc preheating

A welding method and technology of melting and brazing, which is applied in the field of arc melting and brazing of titanium-aluminum dissimilar alloy TIG arc preheating, can solve the problems of reducing the mechanical properties of joints, being easy to be polluted by air, and intensifying metallurgical reactions. The effects of popularization and application, reduction of sensitivity, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

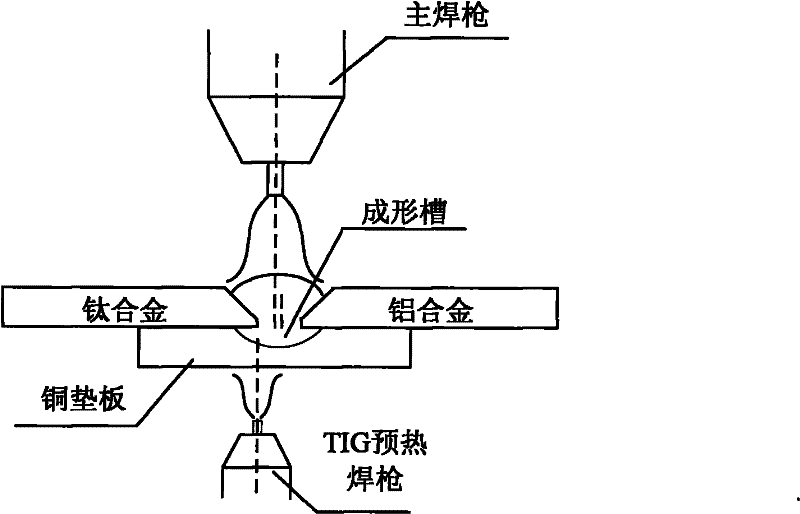

[0018] Example 1: Combining figure 1 , figure 2 , the present invention a kind of titanium-aluminum dissimilar alloy TIG electric arc preheating arc melting and brazing welding method, it is characterized in that: step is as follows:

[0019] Step 1: Test equipment and workpiece preparation: 2 sets of AC and DC dual-purpose TIG welding machines, 2 bottles of argon gas, 1 set of automatic walking mechanism, 1 set of rigid fixture hollowed out at the bottom, 1 piece of copper backing plate with argon-filled forming groove , Work piece: Titanium alloy plate and aluminum alloy plate of equal thickness with Y-shaped groove of equal size on the side;

[0020] Step 2: Use rigid fixtures and copper backing plates to clamp titanium alloy plates and aluminum alloy plates of equal thickness with Y-shaped grooves of equal size on the sides;

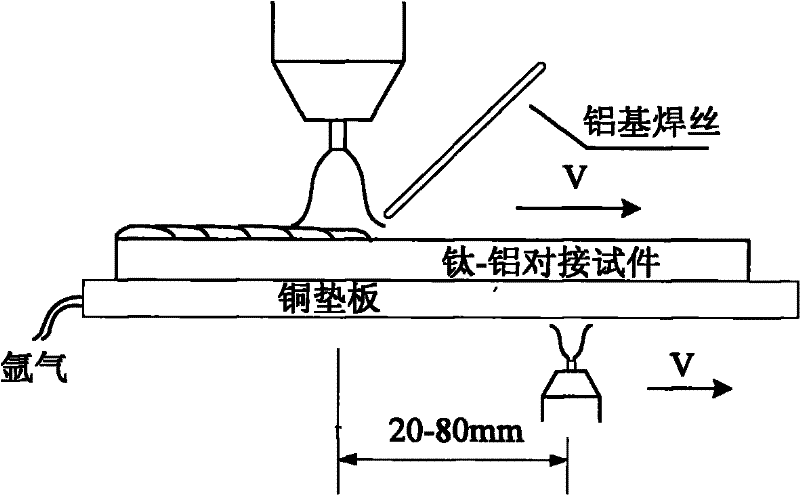

[0021] Step 3: Place the main welding torch and the TIG preheating welding torch vertically on the groove position on the front and back of the w...

Embodiment 2

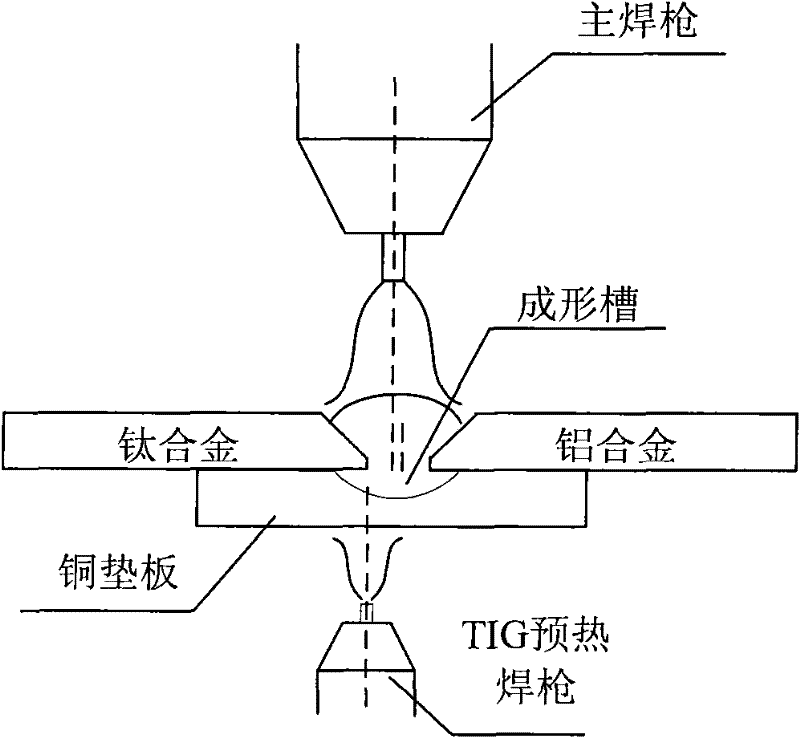

[0026] Example 2: Combining figure 1 , figure 2 , the arc melting and brazing welding method for titanium-aluminum dissimilar alloy TIG arc preheating of the present invention mainly heats the copper backing plate through the back TIG arc, relies on the copper backing plate to heat the butt joint of the titanium-aluminum joint, and passes through the forming groove Constrained forming and argon protection on the front and back sides realize the high-quality connection of titanium-aluminum dissimilar alloy arc melting and brazing, solve the contradiction between the energy control of the side line of the titanium alloy and the wetting and spreading of the bottom, and ensure the formation between the titanium alloy and the liquid filling material. Ideal brazing interface structure. At the same time, constraining the aluminum alloy side by forming grooves to form a good welded bond is of great significance for the preparation and application of high-quality welded joints of tit...

Embodiment 3

[0027] Example 3: Binding figure 1 , figure 2 , the present invention a kind of titanium-aluminum dissimilar alloy TIG electric arc preheating arc melting and brazing welding method, the steps are as follows:

[0028] (1) Test equipment and workpiece preparation: 2 sets of AC and DC dual-purpose TIG welding machines, 2 bottles of argon gas, 1 set of automatic walking mechanism, 1 set of rigid fixture hollowed out at the bottom, 1 piece of copper backing plate with argon-filled forming groove , Work piece: Titanium alloy plate and aluminum alloy plate of equal thickness with Y-shaped groove of equal size on the side;

[0029] (2) Use rigid fixtures and copper backing plates to clamp the workpiece, place the main welding torch and TIG preheating welding torch vertically on the groove position on the front and back of the workpiece, and connect them with the same set of automatic walking mechanism, and the TIG preheating welding torch is located on the main welding torch The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com