Acid picking method for extracting mineral from serpentine

A technology of minerals and serpentine, applied in the improvement of process efficiency, silicon oxide and other directions, can solve problems such as reducing production costs, and achieve the effects of reducing production costs, realizing large-scale industrial production, and improving development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

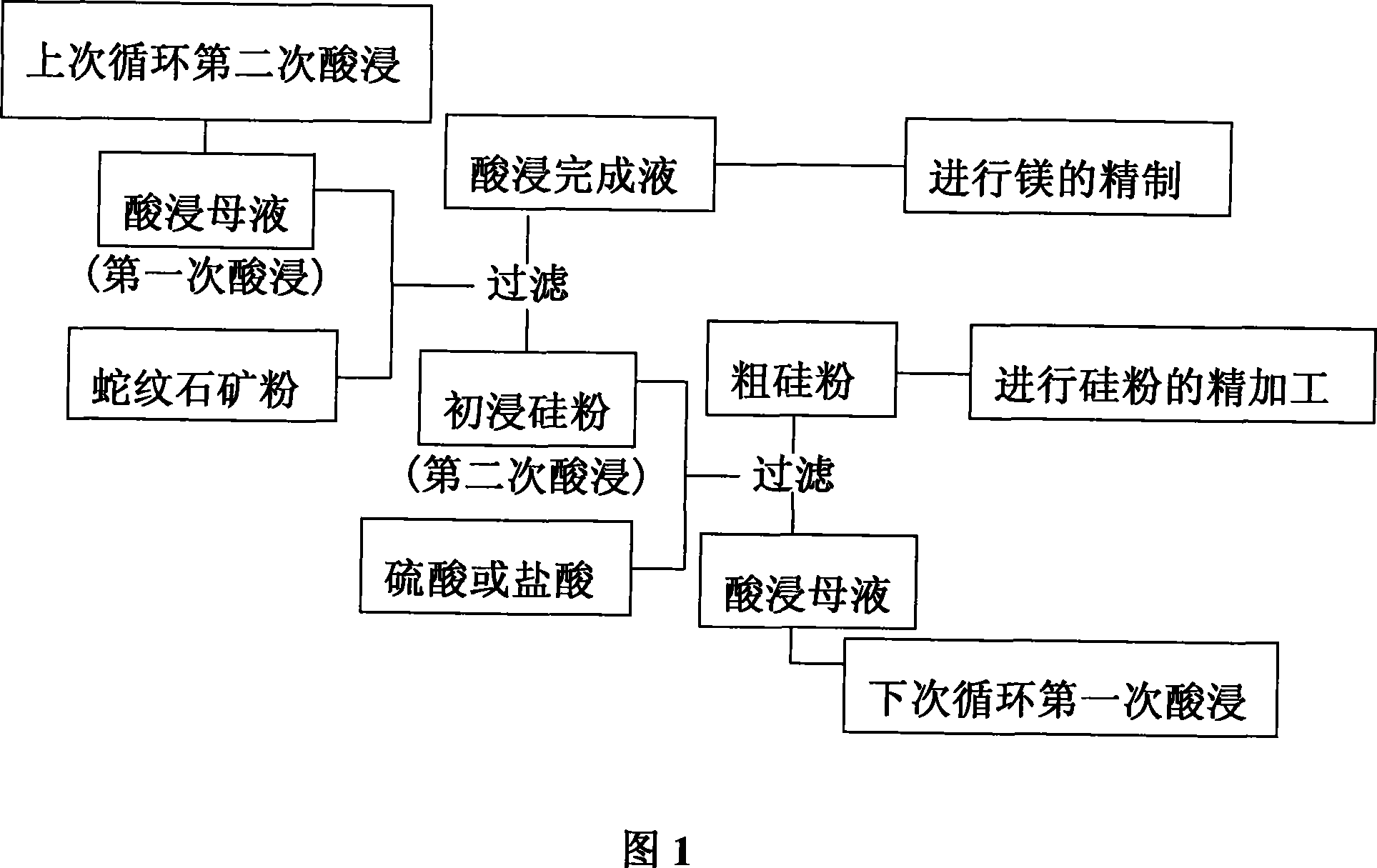

Method used

Image

Examples

example 1

[0020] Add 400g of 80-200 mesh serpentine powder into 1200g of pickling solution, and use a sulfuric acid solution with a concentration of 17% as the pickling solution at the beginning of the process for the first pickling, and the pickling is controlled at 80°C- Within the temperature range of 115°C, stir for 1 hour under normal pressure, filter and separate the rich magnesium sulfate solution with little acid content, which is the completion solution of acid leaching. The filter residue is cleaned of magnesium salt for the second time to become silicon powder for primary immersion, which is ready for the second acid leaching. Slowly add 450g of sulfuric acid with a concentration of 90% into 675g of clear water added with 0.1% to 20% hydrogen fluoride acid leaching aid, and then add the primary silicon powder for the first acid leaching to the acid leaching while taking advantage of the heat of reaction , in the temperature range of 80 ℃ -115 ℃ for the second acid leaching. ...

example 2

[0022] Add 400g of 100-200 mesh serpentine powder into 1400g of pickling solution, and use a sulfuric acid solution with a concentration of 17% as the pickling solution at the beginning of the process for the first pickling.

[0023] The acid leaching is controlled within the temperature range of 80°C-115°C, stirred at normal pressure for 2 hours, and the magnesium sulfate-rich solution with little acid content is filtered and separated, which is the completion solution of the full acid leaching process. The filter residue is cleaned of magnesium salt for the second time to become silicon powder for primary immersion, which is ready for the second acid leaching. Slowly add 450g of 98% sulfuric acid into 675g of clear water added with 0.1% to 20% hydrogen fluoride acid leaching auxiliary agent, and then add the primary silicon powder for the first acid leaching to the acid leaching while taking advantage of the heat of reaction. The second acid leaching is carried out in the te...

example 3

[0025] Add 400g of 80-200 mesh serpentine powder into 1480g of pickling solution, and use a 12% hydrochloric acid solution as the pickling solution at the beginning of the process for the first pickling. The acid leaching is controlled within the temperature range of 80°C-115°C, stirred at normal pressure for 2 hours, and the magnesium chloride-rich solution with little acid content is filtered and separated, which is the completion solution of the whole acid leaching process. The filter residue is cleaned of magnesium salt for the second time to become silicon powder for primary immersion, which is ready for the second acid leaching. 900g concentration is that 30% hydrochloric acid is slowly added to the clear water of 675g that has added 4% sodium fluoride acid leaching auxiliary agent, then while taking advantage of the heat of reaction, the initial leaching silicon powder of the first acid leaching is added in the acid leaching, The second acid leaching is carried out in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com