Method for manufacturing ceramic filled polytetrafluoroethylene glass fiber copper-clad substrate

A technology of polytetrafluoroethylene and glass fiber, which is applied in the field of copper-clad substrate manufacturing with ceramic-filled polytetrafluoroethylene glass fiber, can solve the problems of affecting the use effect, low dielectric constant, insufficient strength, etc., and achieve improved peel strength , high thermal conductivity, and the effect of improving high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

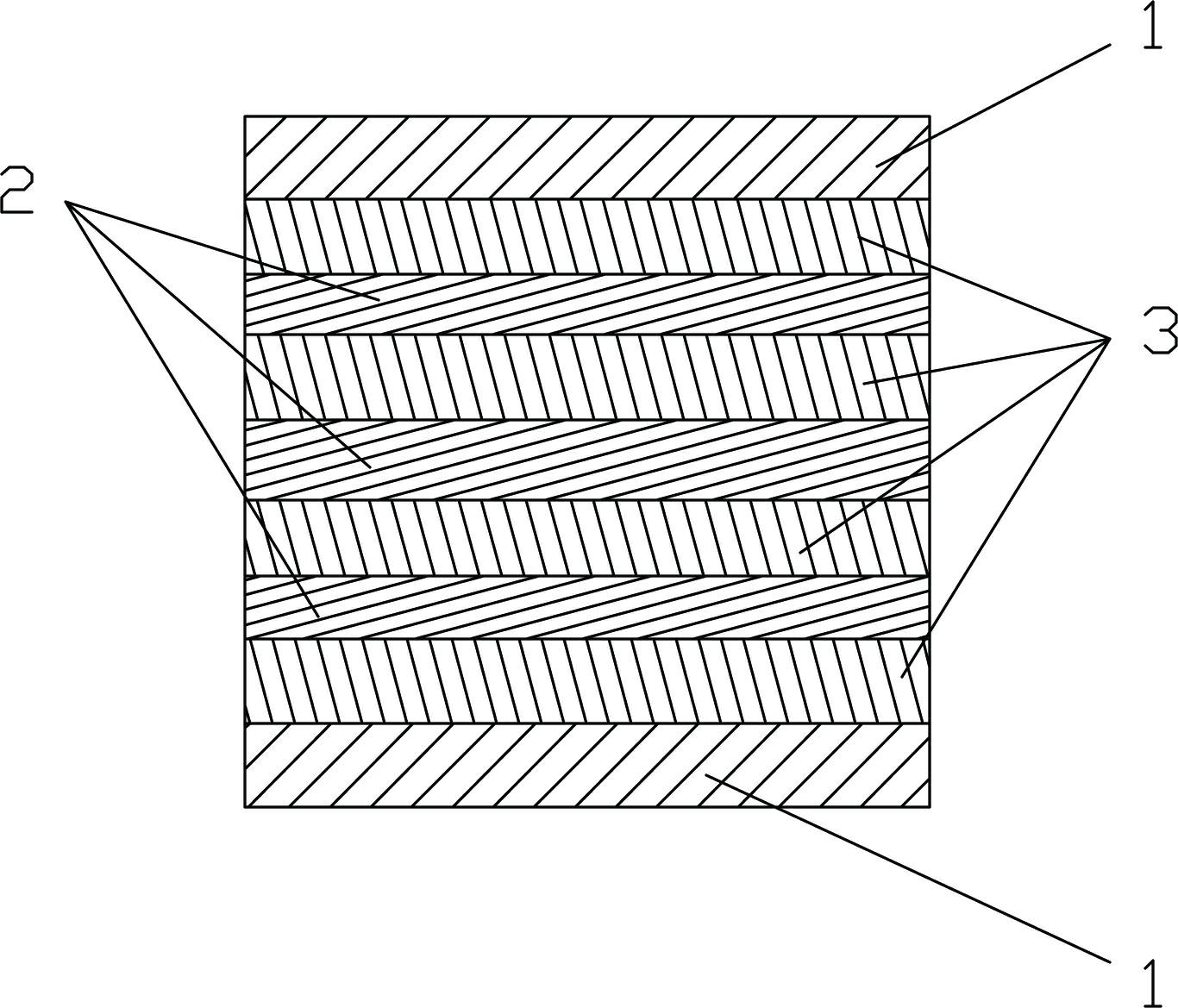

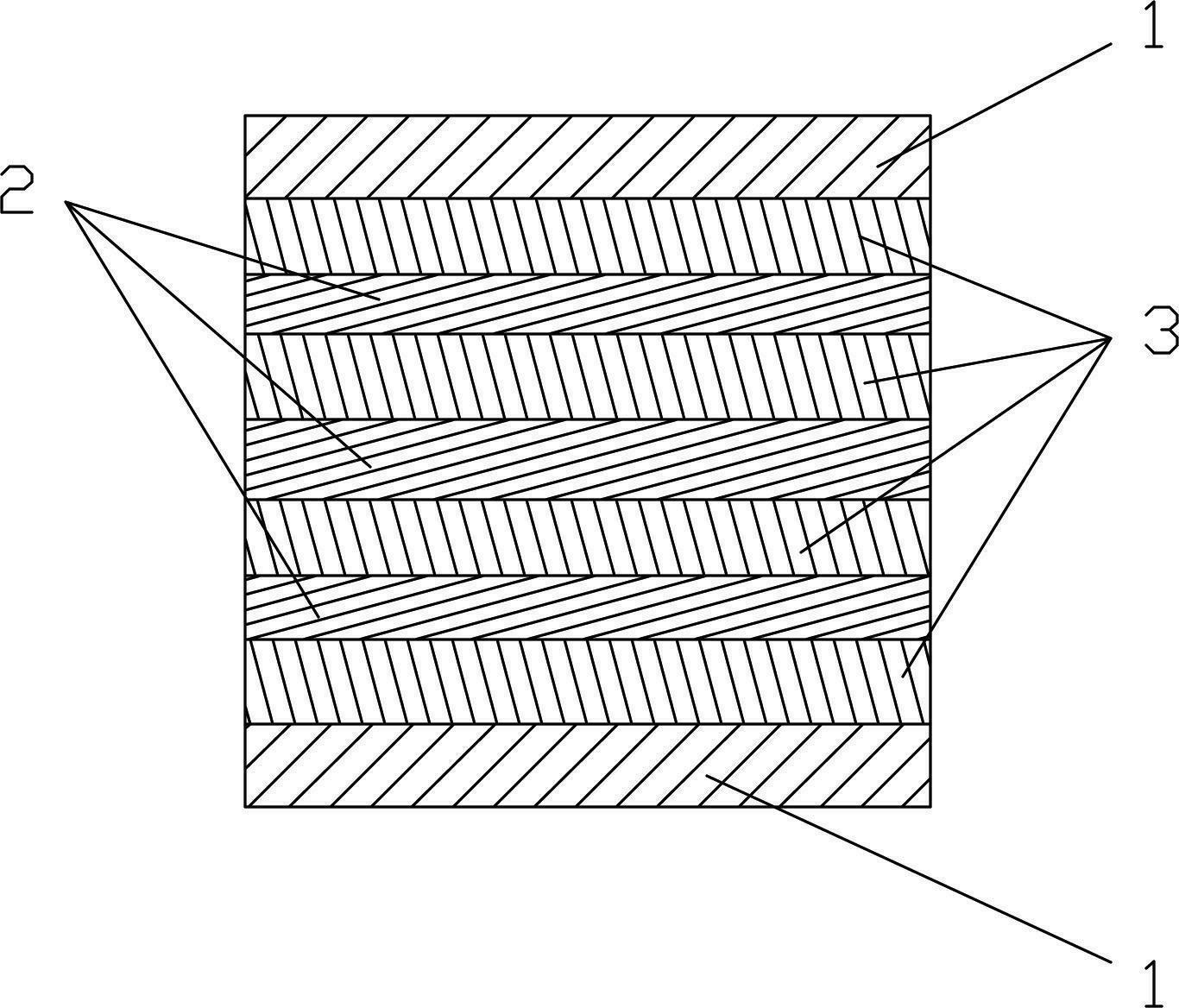

[0017] refer to figure 1 . A method for manufacturing a ceramic-filled polytetrafluoroethylene glass fiber copper-clad substrate, its technological process comprises successively:

[0018] 1) Configure polytetrafluoroethylene liquid;

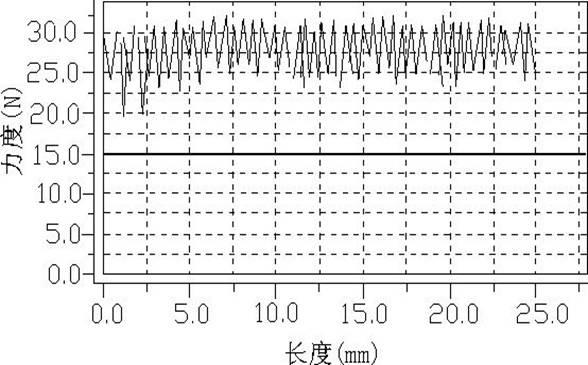

[0019] 2) Stir the prepared polytetrafluoroethylene liquid, ceramic powder and dispersant with high-speed stirring equipment to form a solvent, so that the prepared solvent can be well combined with the glass fiber cloth, which is reflected in the macroscopic view of the glass fiber cloth and the glass fiber cloth. Copper foil peel strength increases;

[0020] 3) After the glass fiber cloth is treated in a dewaxing machine heated at 400°C for 30 minutes, it is immersed in the silane coupling agent surface modification solution for 5 to 10 minutes, and after the sintering machine is baked for 30 minutes, the glue is solidified on the glass fiber cloth After the treatment is completed, the glass fiber cloth is soaked in the solvent to form the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com