Powder plasma welding device and welding method

A technology of a welding device and a welding method, applied in the directions of plasma welding equipment, plasma, welding equipment, etc., can solve problems such as fusion welding that is not suitable for mutual bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

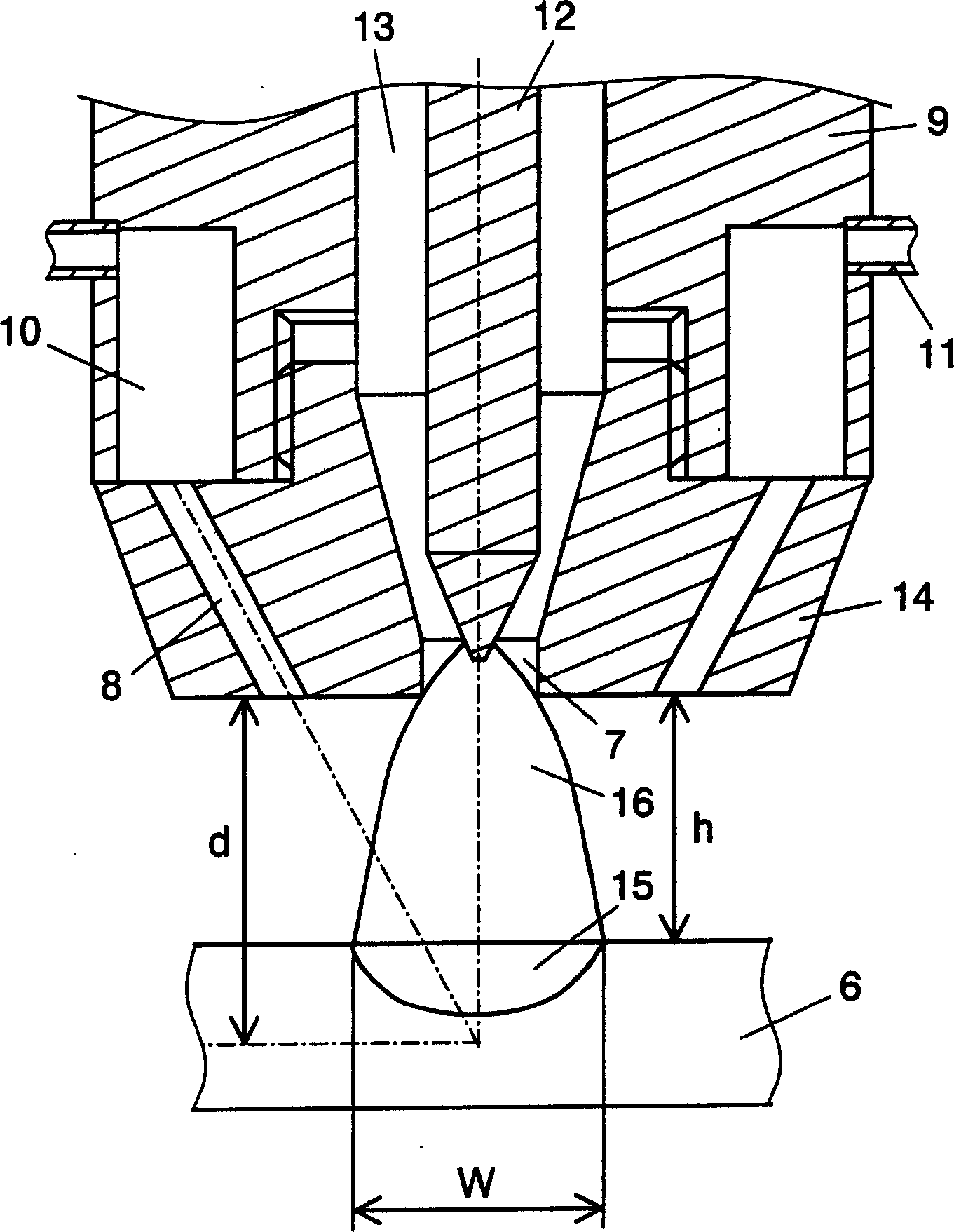

[0014] exist figure 2 Among them, the powder plasma welding device has: a welding torch 3; a power supply 1 that supplies power to the welding torch 3; a feeding device 2 that supplies powder to the welding torch 3; a gas supply device 4 that supplies gas to the welding torch 3 and the feeding device 2; 1 and the feeding device 2 output the control device 5 of the setting signal; the workpiece 6.

[0015] The description of the operation of the welding device with the above structure is as follows. The control device 5 outputs the welding condition setting value of the powder feeding amount and the welding start signal to the power source 1 and the feeding device 2 . The feeding device 2 determines the powder feeding amount level according to the powder feeding amount setting value from the control device 5 . The power supply 1 determines the output power level to the welding torch 3 according to the set value input from the control device 5 . In addition, the power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com