Elastic graphene aerogel and preparation method and application thereof

A graphene hydrogel and elastic graphite technology, which is applied in the direction of airgel preparation, graphene, separation methods, etc., can solve the problems of poor elasticity and hydrophobicity, low hydrophobicity and adsorption, and increased production costs. To achieve the effect of preventing excessive growth of ice crystals, increasing hydrophobicity and improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

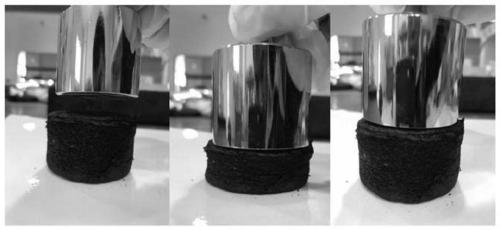

Image

Examples

preparation example Construction

[0027]

[0028] The preparation steps of elastic graphene airgel of the present invention comprise: (1) the step of preparing graphene oxide dispersion; (2) the step of preparing mixed solution; (3) the step of preparing graphene hydrogel; (4) Graphene hydrogel soaking step and (4) freezing and normal pressure drying step. A detailed description is given below.

[0029] In step (1), the graphene oxide and the reducing agent are dispersed in water to obtain a graphene oxide dispersion. The graphene oxide of the present invention may be graphene oxide prepared by the improved Hummers method, but is not limited to graphene oxide prepared by the improved Hummers method. Graphene oxide prepared by liquid phase method, mechanical method, electrochemical oxidation method and other methods can be used in the preparation method of the present invention.

[0030] In order to disperse the graphene oxide in water more fully, it can be treated with ultrasonic vibration for 8-35 minutes...

Embodiment 1

[0049] (1) Add 900 mg of ascorbic acid and 360 mg of graphene oxide into 60 ml of water, and ultrasonically vibrate for 10 minutes to obtain a graphene oxide dispersion (the concentration of graphene oxide is 6 mg / ml).

[0050] (2) Add 3 ml of an aqueous sodium dodecylbenzenesulfonate solution with a concentration of 50 mg / ml into the graphene oxide dispersion, and stir at a rotational speed of 10000 rpm to obtain a mixed solution.

[0051] (3) The mixture was reacted at 80° C. for 6 h, and then naturally cooled to 25° C. to obtain graphene hydrogel.

[0052] (4) Soak and wash the graphene hydrogel with 1vol% ethanol aqueous solution for 24 hours, and then soak it in 14vol% ammonia solution for 5 hours at a soaking temperature of 25° C. to obtain the soaked graphene hydrogel.

[0053] (5) The soaked graphene hydrogel was frozen at -45°C, then heated to 25°C to melt, and then dried at normal pressure and 65°C to obtain elastic graphene aerogels.

Embodiment 2

[0055] (1) Add 900 mg of ascorbic acid and 240 mg of graphene oxide into 60 ml of water, and ultrasonically vibrate for 10 minutes to obtain a graphene oxide dispersion (graphene oxide concentration is 4 mg / ml).

[0056] (2) Add 3 ml of an aqueous sodium dodecylbenzenesulfonate solution with a concentration of 50 mg / ml into the graphene oxide dispersion, and stir at a rotational speed of 10000 rpm to obtain a mixed solution.

[0057] (3) The mixture was reacted at 80° C. for 6 h, and then naturally cooled to 25° C. to obtain graphene hydrogel.

[0058] (4) Soak and wash the graphene hydrogel with 1vol% ethanol aqueous solution for 24 hours, and then soak it in 14vol% ammonia solution for 5 hours at a soaking temperature of 25° C. to obtain the soaked graphene hydrogel.

[0059] (5) The soaked graphene hydrogel was frozen at -45°C, then heated to 25°C to melt, and then dried at normal pressure and 65°C to obtain elastic graphene aerogels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com