Throttle valve device

A technology of throttle and throttle valve, which is applied in engine control, machine/engine, mechanical equipment, etc. It can solve the problems of poor freezing release and increased contact area, so as to improve release, reduce freezing, and improve heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0044] Hereinafter, a first embodiment embodying the throttle device of the present invention will be described in detail with reference to the drawings. The throttle device of the present embodiment is provided in an intake passage of an automobile engine, and is used to adjust the intake air amount of the engine.

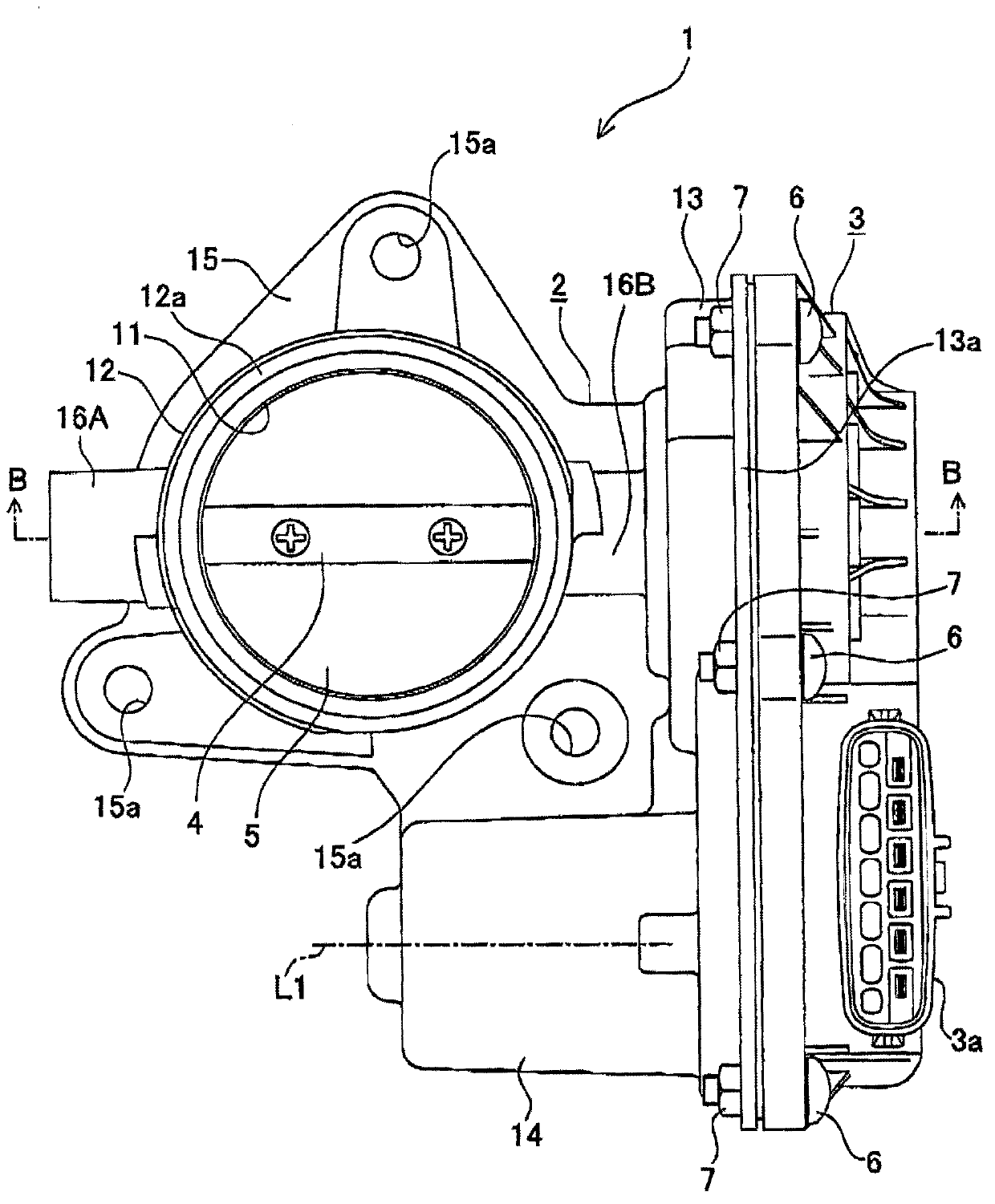

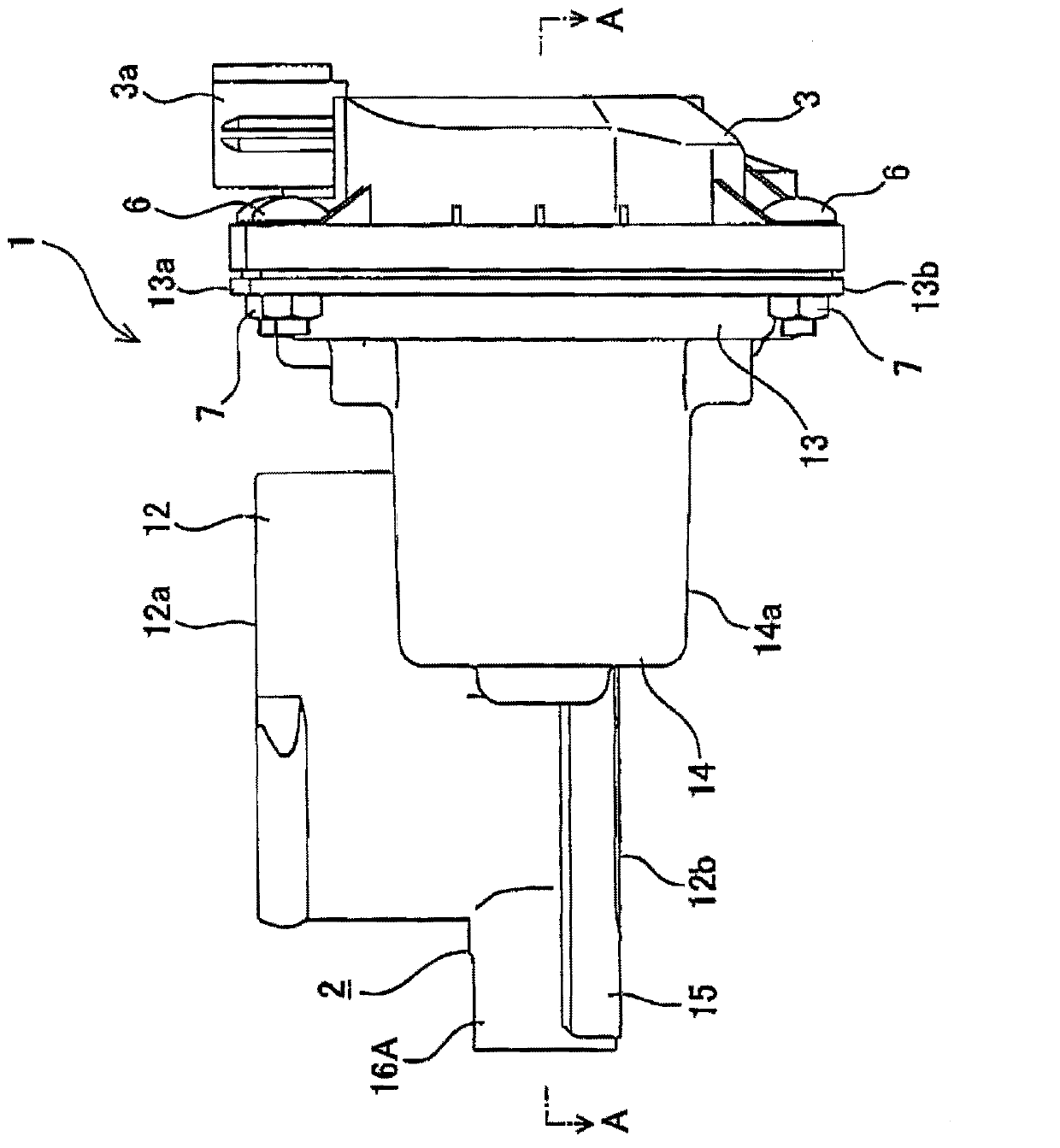

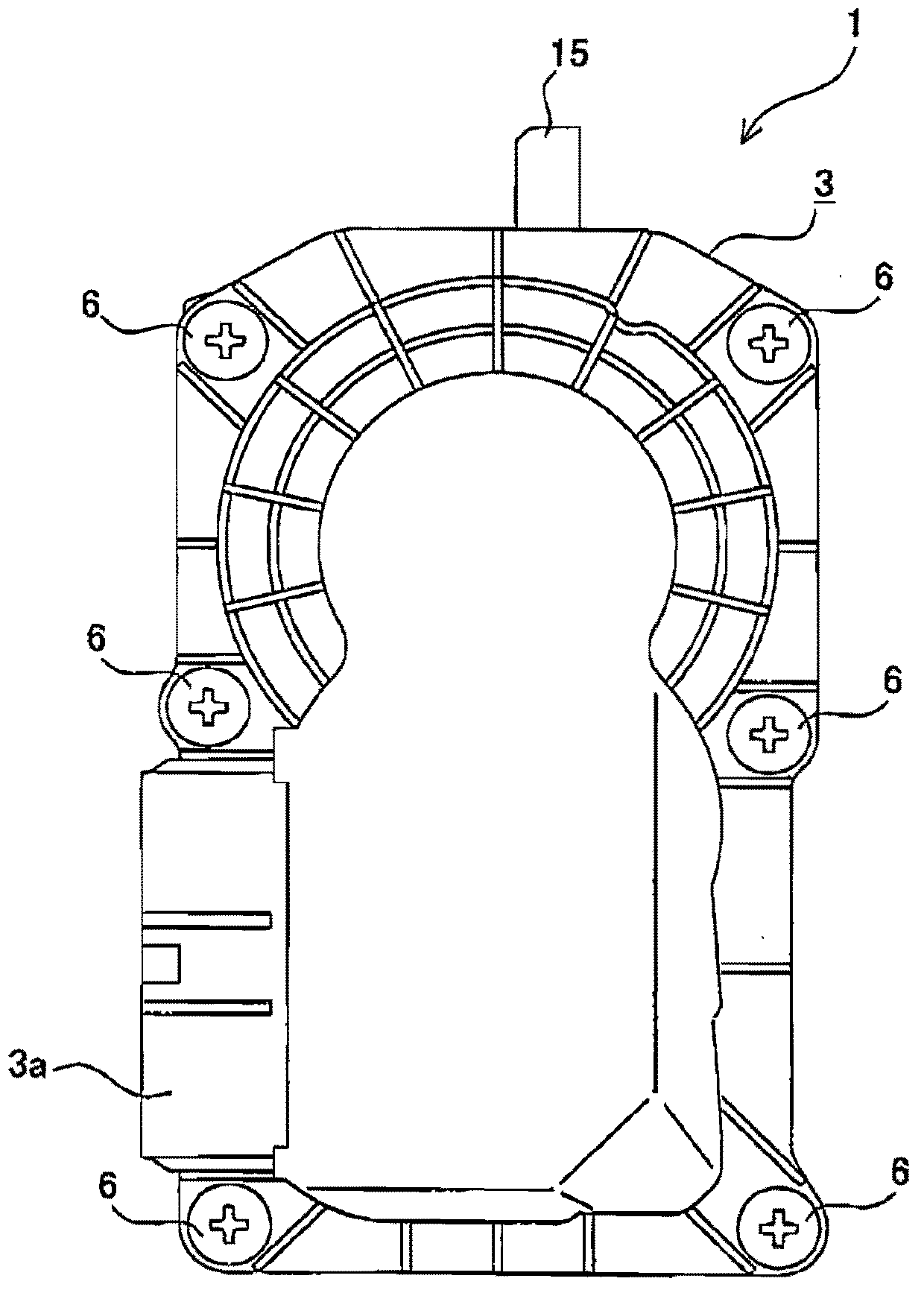

[0045] figure 1 The throttle device 1 according to the present embodiment is shown in a front view. figure 2 middle use figure 1 The bottom view of shows the throttle device 1. image 3 middle use figure 1 The right side view of shows the throttle device 1. like figure 1 , figure 2 As shown, the throttle device 1 includes a metal throttle body 2 and a resin gear cover 3 .

[0046] The throttle body 2 includes: a cylindrical throttle tube 12, which has a hole 11 communicating with the intake passage of the engine; a gear box 13, which accommodates the gear mechanism 9 inside (refer to Figure 4 ) etc.; motor casing 14, which accommodates the motor 8 i...

no. 2 Embodiment approach

[0074] Next, a second embodiment embodying the throttle device of the present invention will be described in detail with reference to the drawings.

[0075] In addition, in the following description, the same code|symbol is attached|subjected to the same component as 1st Embodiment, and description is abbreviate|omitted, and it demonstrates centering on the difference from 1st Embodiment.

[0076] The difference between the configuration of the present embodiment and the configuration of the first embodiment lies in the shape of the manifold 51 connected to the throttle tube 12 . Figure 15 A state in which the manifold 51 is connected to the throttle pipe 12 is schematically shown in a sectional view. That is, in this embodiment, if Figure 15 As shown, the intake passage 52 in the manifold 51 is formed such that the diameter gradually decreases from the one end 51 a of the manifold 51 toward the downstream side.

[0077] Therefore, since the intake passage 52 of the manifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com