Nozzle tip of pulverized coal burner

A pulverized coal burner, nozzle head technology, applied in the direction of burner, burner burning powder fuel, combustion method, etc., can solve the problems that the nozzle head cannot perform the specific function of the nozzle head, the shared rod falls off, cracks, etc., and achieves improvement Abrasion phenomenon and detachment phenomenon, replacement cost saving, and effect of increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

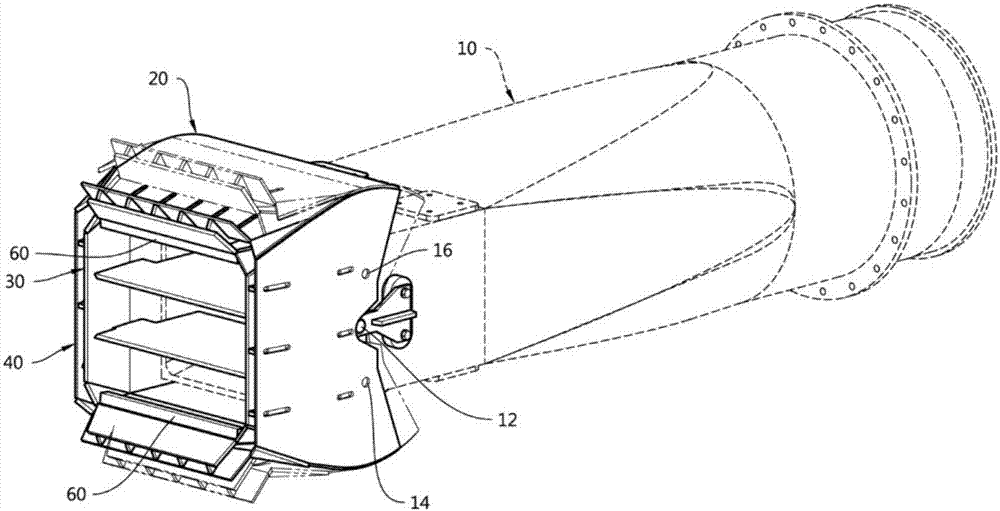

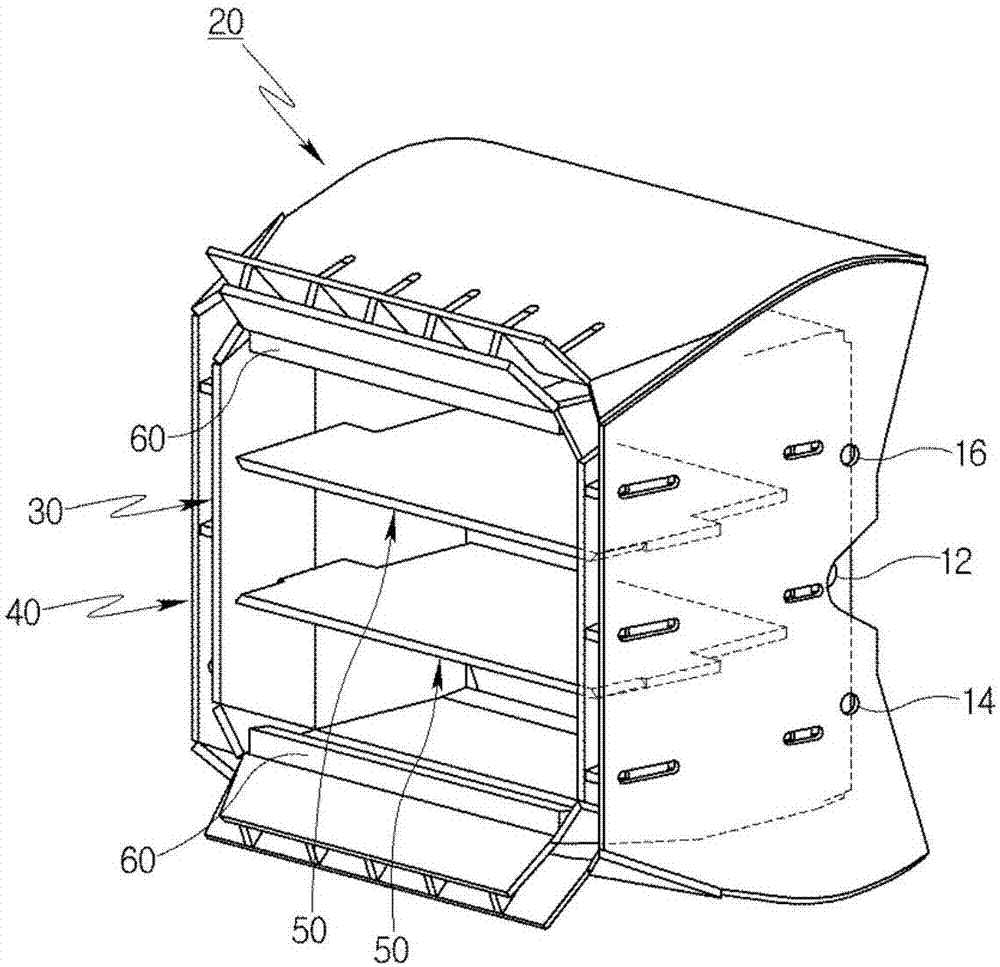

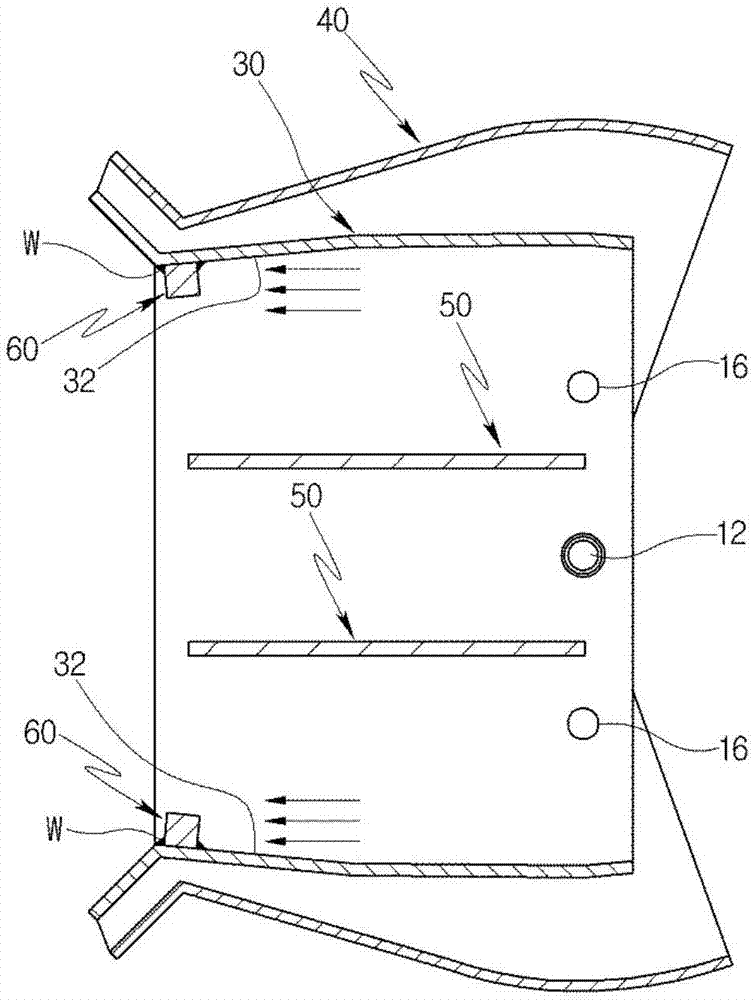

[0045] Below, refer to the attached Figure 4 to Figure 11 A preferred embodiment of the nozzle tip of the pulverized coal burner of the present invention will be described.

[0046] In addition, the terms described later are terms defined in consideration of the functions in the present invention, which can be changed according to the user's, operator's intention or custom, and the following examples do not limit the claims of the present invention, but merely Examples of constituent elements set forth in the claims of the present invention.

[0047] In order to clearly describe the present invention, parts irrelevant to the description are omitted, and the same reference numerals are attached to the same or similar constituent elements throughout the specification. Throughout the specification, when it is mentioned that certain components "include" certain components, unless there is a specific statement to the contrary, it does not mean that other components are excluded, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com