elastic bushing

A technology of elastic bushing and elastic part, which is applied in the direction of axle box installation, device for lateral relative movement between underframe and bogie, etc., can solve the problems of low rigidity ratio and difficult realization, and achieve reasonable strength balance and stable performance , Ease of use and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

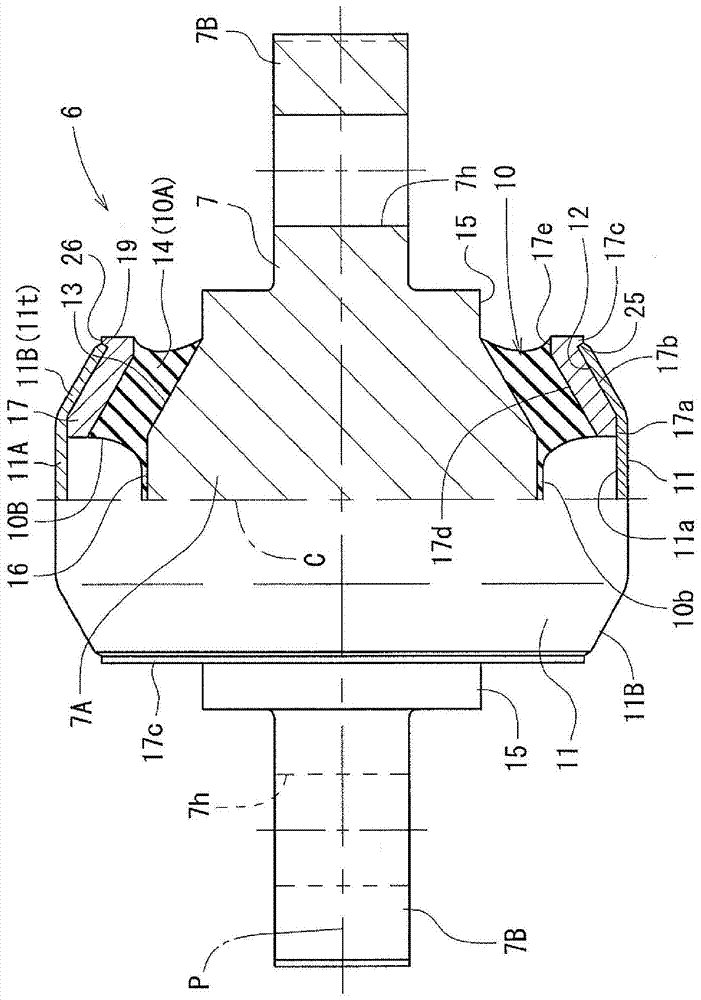

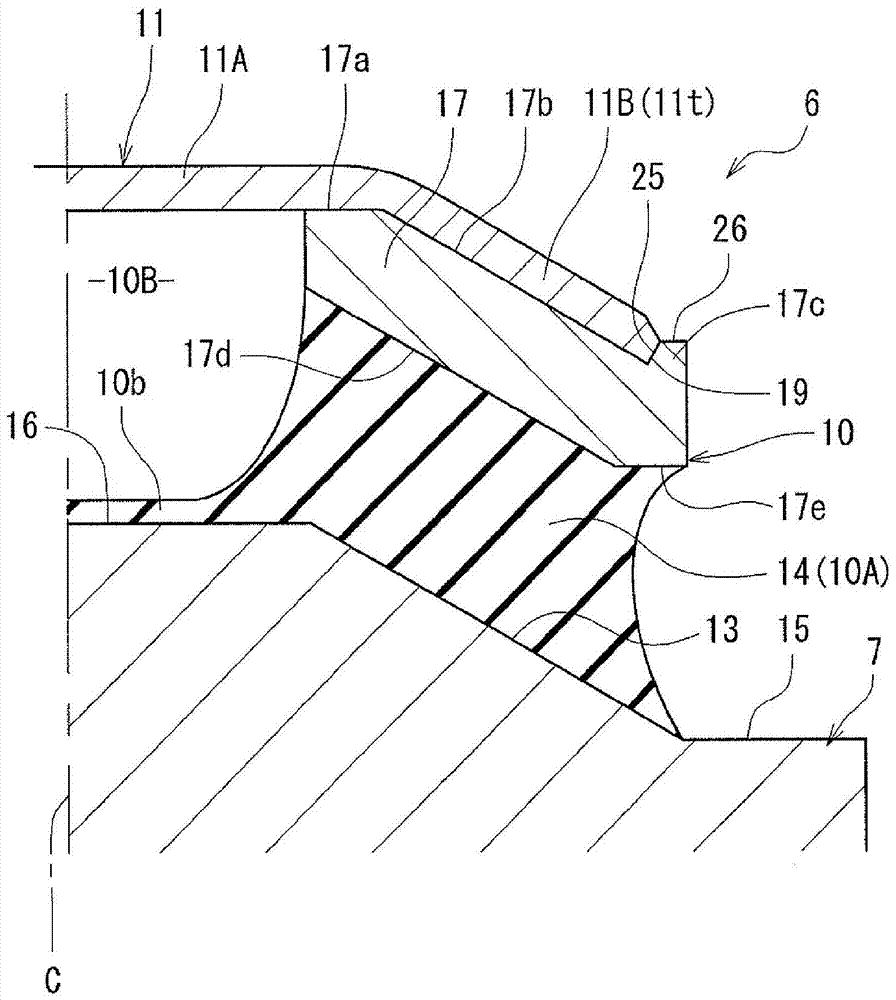

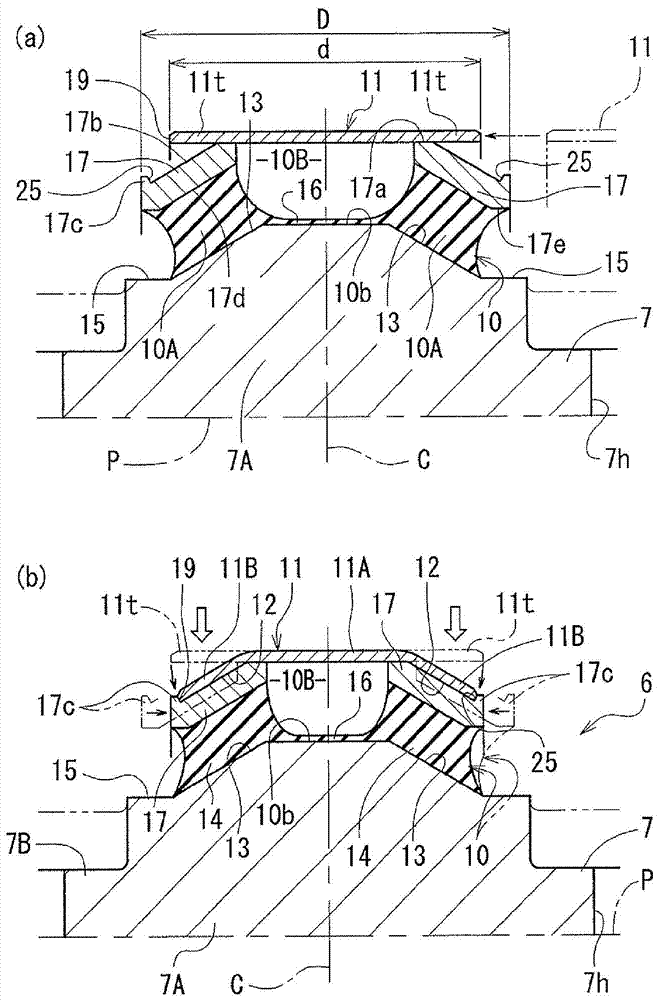

[0060] Figure 4 The outline of the axle-beam device of a railway vehicle is shown, in which 1 is an axle, 2 is an axle box part, 3 is an axle beam, 4 is a housing part, 5 is a wheel attached to the axle 1, and 6 is an elastic bushing (also known as anti-vibration bushing), 8 is a trolley frame.

[0061] The axle beam 3 extends from the axle box portion 2 for supporting the axle 1 toward the vehicle traveling direction (arrow Y direction), and the elastic bush 6 is fitted into a cylindrical cover portion 4 formed at one end of the axle beam 3 . 8A is a bifurcated support bracket for supporting the center shaft 7 of the elastic bush 6 , and is formed to protrude downward from the dolly frame 8 .

[0062] Such as Figure 4-Figure 6 As shown, the outer member 11 of the elastic bush 6 is fitted and fixed in the fitting hole 4H of the cover part 4, and although not shown, both ends of the central axis 7 of the elastic bush 6 are fixed by means of bolts. etc. are non-rotatably su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com