Mechanical scraping and electrical heating combined snow removal greenhouse

A combined, electric heating technology, applied in the field of agricultural greenhouses, can solve the problems of reducing light, mechanical damage, and high labor intensity, and achieve the effects of reducing crops from freezing, improving service life, and facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

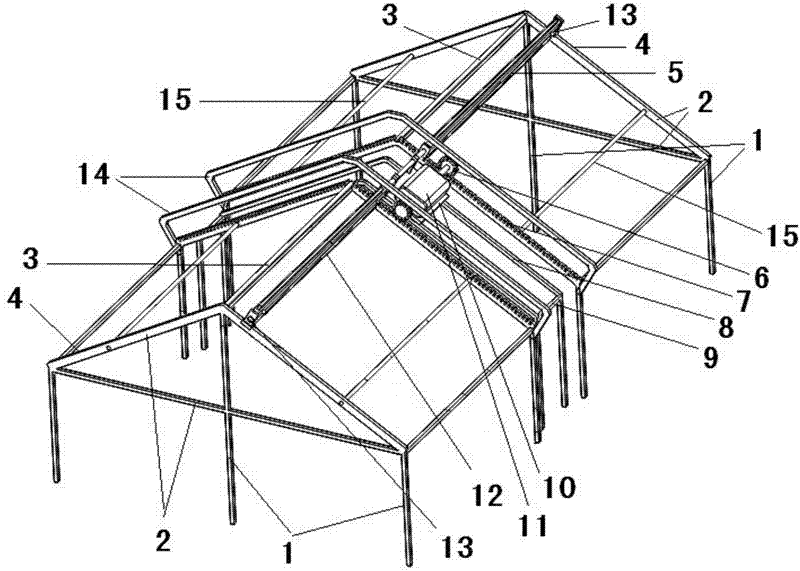

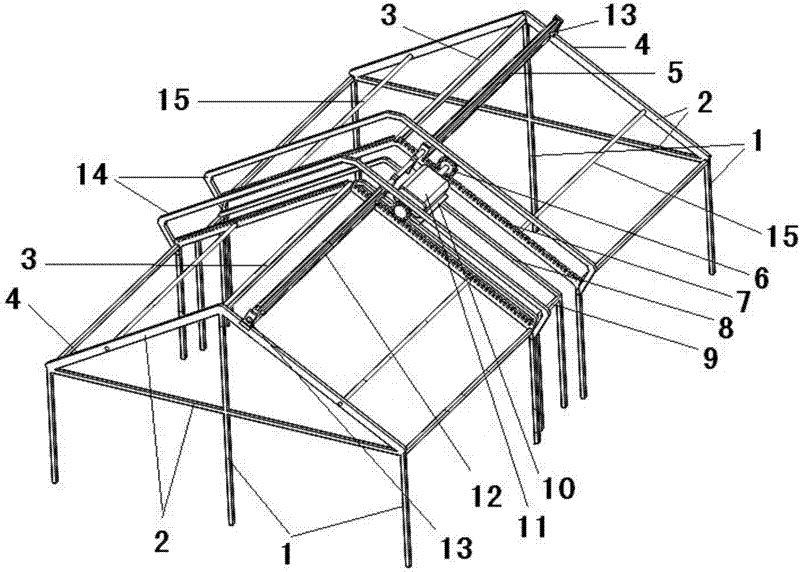

[0034] The specific implementations of the mechanical scraping and electric heating combined snow removal greenhouse of the present invention are given below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited to the following implementations.

[0035] See attached figure 1 , a mechanical scraping and electric heating combined snow removal greenhouse, the supporting column 1, the beam 2, the top beam 3 and the plastic film of the greenhouse can be used as the construction materials of the existing agricultural greenhouse. Use support column 1, crossbeam 2 and top beam 3 together to form the frame structure of the greenhouse, then cover the frame structure with plastic film for the greenhouse, set doors and windows (if windows are required), and form the basic form of the agricultural greenhouse. Since the frame structure of the greenhouse is load-bearing, sufficient consideration should be given to the materials and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com