Moving-bed retorting furnace heated comprehensively by radiant tube and circulating airflow

A technology of radiant tube heating and circulating air flow, applied in indirect heating dry distillation, direct heating dry distillation, coke oven, etc. High heat rate, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

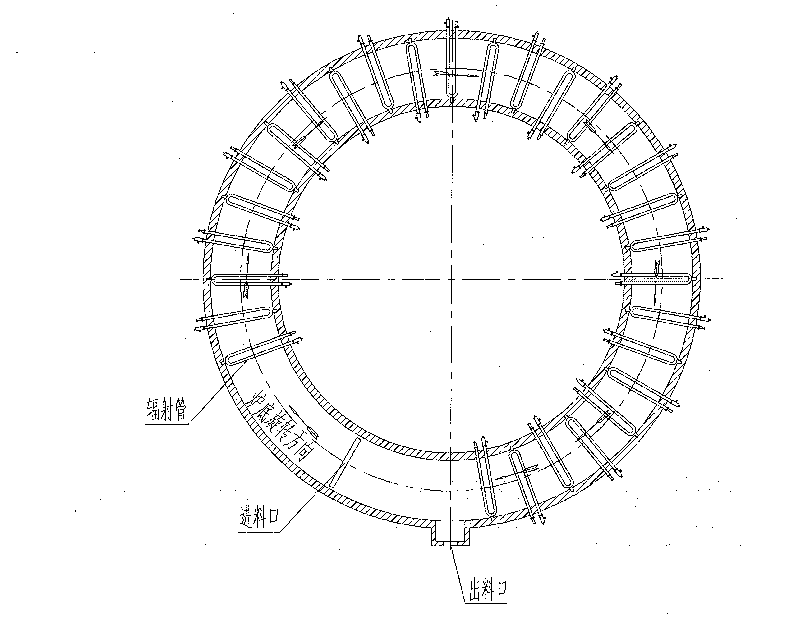

[0041] Specific embodiment one, such as figure 2 As shown, the furnace can be ring-shaped, the hearth and the bottom of the furnace are ring-shaped, and the bottom of the furnace can rotate horizontally in the hearth;

specific Embodiment 2

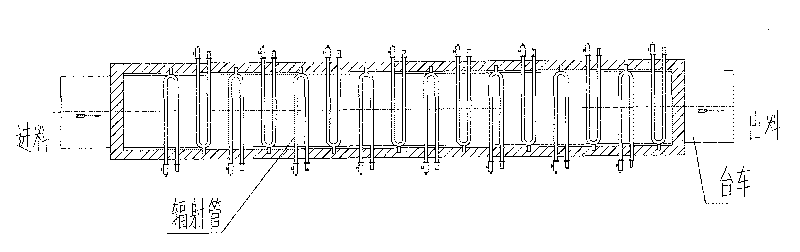

[0042] Specific embodiment two, such as image 3 As shown, the furnace can also be straight-through (tunnel) shaped, with the hearth being able to move in and out of the hearth at one end.

[0043] The furnace can also be square, and the bottom of the furnace can move back and forth inside the furnace. Or take other shapes.

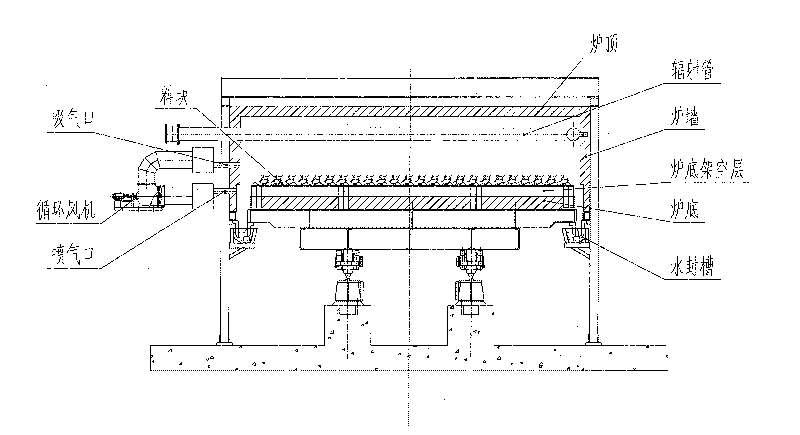

[0044] see you again figure 1 , The bottom of the furnace is with an overhead layer structure, and the overhead layer of the furnace bottom is supported by the steel structure bracket of the furnace bottom. Lay steel plates on the overhead layer, and lay heat insulation material on the bottom of the overhead layer (that is, on the steel structure bracket of the furnace bottom).

[0045] Bottom steel structure brackets, supporting rollers, guiding (or centering) devices, driving devices, tracks, etc. constitute the furnace bottom machinery. The driving device can be electric machinery, also can be hydraulic motor or hydraulic cylinder etc.

[0046] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com