Composite sleeve double-helix heat exchanger

A composite casing, shell-and-tube heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problem of poor fluid circulation, low flow rate, limited improvement of shell-side circulation, etc. problems, to achieve the effect of increasing heat transfer coefficient, increasing heat transfer intensity and rate, and decreasing convective heat transfer thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

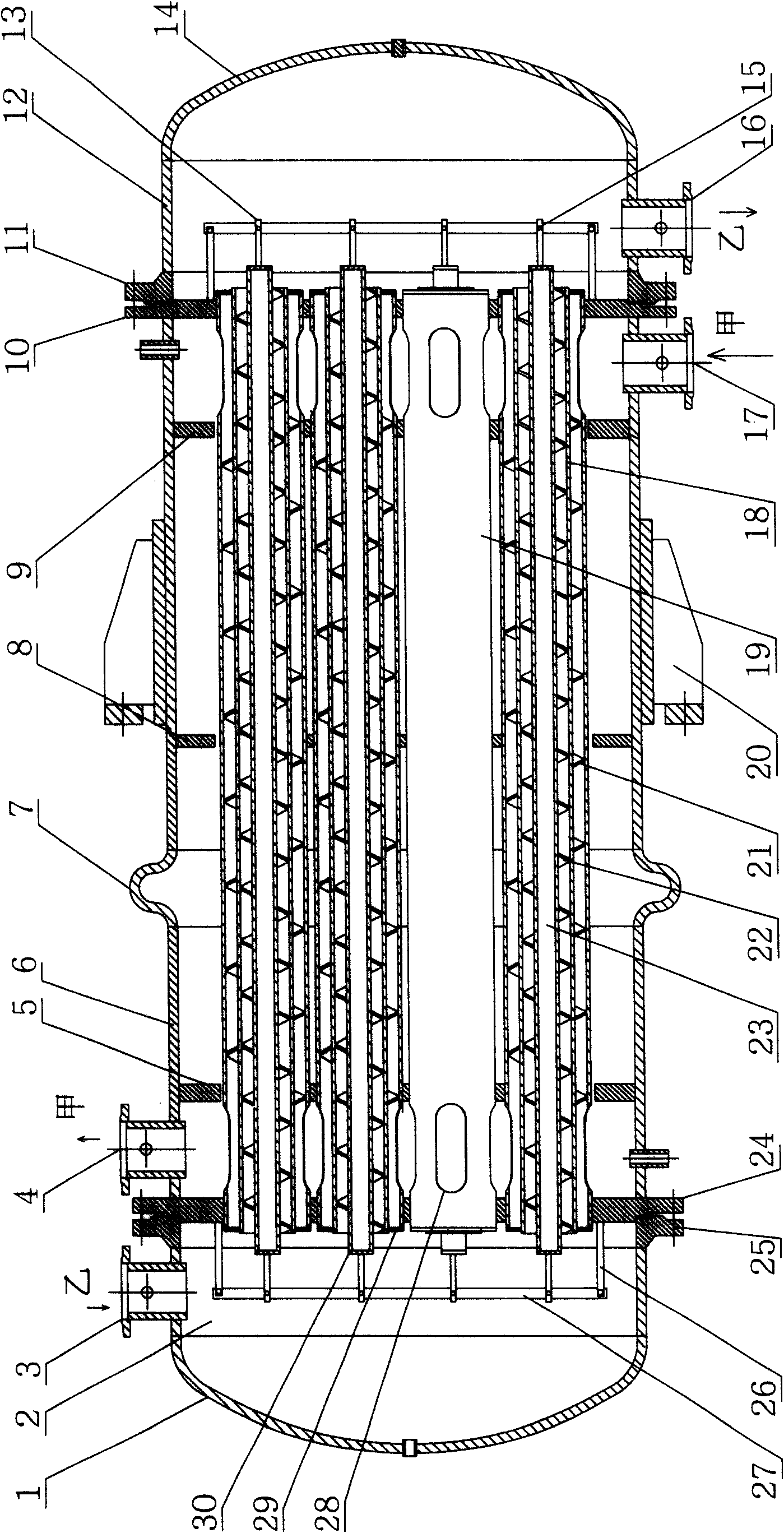

[0028] Composite casing double-helix heat exchanger, its composition includes: a cylinder 6 with a fluid inlet 17, an outlet 4 and an expansion joint 7, the left inner tube plate 5 is fixed near the left end of the cylinder 6, and the The left end of the cylindrical body 6 is fixed with a left outer tube plate 24, the near right end of the cylindrical body 6 is fixed with a right inner tube plate 9, the right end of the cylindrical body 6 is fixed with a right outer tube plate 10, the cylindrical body 6 An intermediate support tube plate 8 is fixed in the middle, a support 20 is fixed in the middle of the cylinder 6, the left end of each outer tube 19 of the heat exchange tube bundle is fixed on the left outer tube plate 24, and the right outer tube The right end of each outer tube 19 of the heat exchange tube bundle is fixed on the plate 10, the left end of the outer tube 19 is fixed on the left end of the outer tube 29, and the right end of the outer tube 19 is fixed on the r...

Embodiment 2

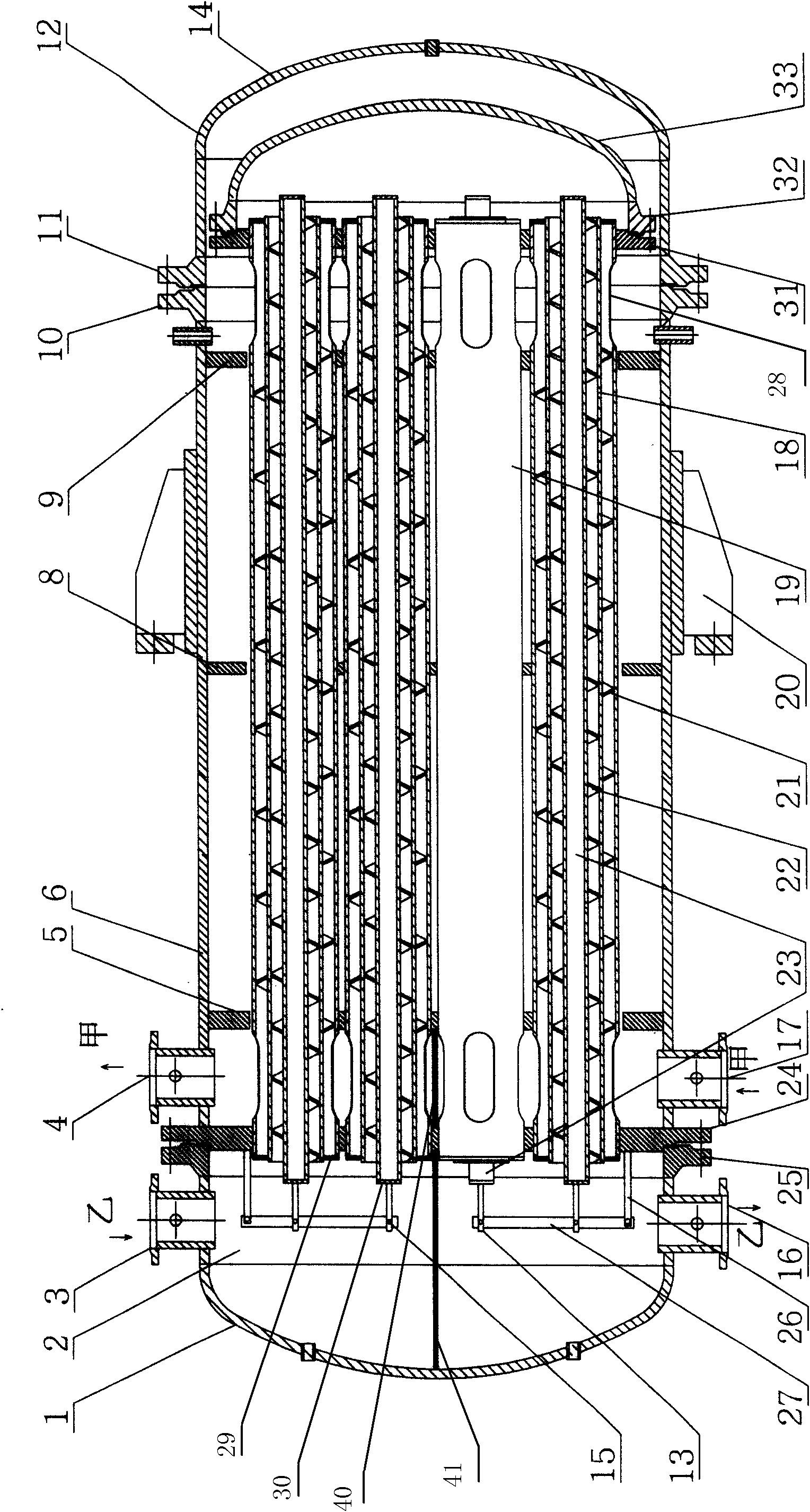

[0031] Composite casing double-helix heat exchanger, its composition includes: a cylinder 6 with a fluid inlet 17, an outlet 4 and an expansion joint 7, the left inner tube plate 5 is fixed near the left end of the cylinder 6, and the A left outer tube plate 24 is fixed at the left end of the cylinder body 6, a right inner tube plate 9 is fixed near the right end of the cylinder body 6, a cylinder right flange 10 is fixed at the right end of the cylinder body 6, and the cylinder body The middle part of 6 is fixed with an intermediate support tube plate 8, the middle part of the cylinder body 6 is fixed with a support 20, the left outer tube plate 24 is fixed with a partition 40, and the left outer tube plate 24 is fixed with a replacement The left end of each outer tube 19 of the heat pipe bundle, the right end of each outer tube 19 of the heat exchange tube bundle is fixed with a floating head tube plate 31, and the floating head tube plate 31 is connected to the floating head...

Embodiment 3

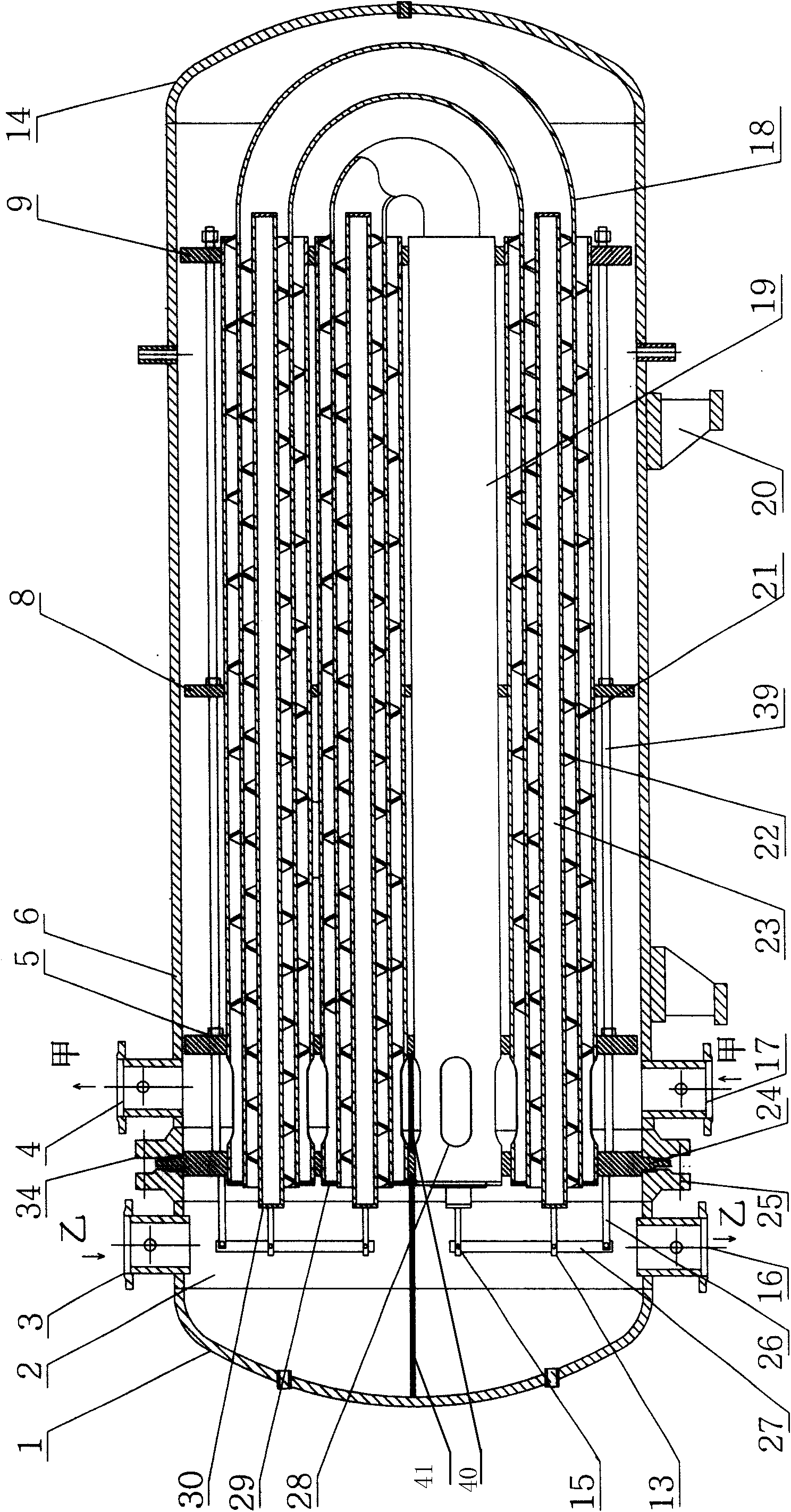

[0034] Composite casing double-helix heat exchanger, its composition includes: a cylinder 6 with a fluid inlet 17, an outlet 4 and an expansion joint 7, the left end of the cylinder 6 is fixed with a cylinder left flange 34, the cylinder The right end of the body 6 is fixed with a cylinder right head 14, the middle part of the cylinder 6 is fixed with a support 20, the cylinder left flange 34 is sealed and connected with the left outer tube plate 24, and the left outer tube A partition 40 is fixed on the plate 24, the left end of each outer tube 19 of the heat exchange tube bundle is fixed on the left outer tube plate 24, and the left inner tube plate 5 is fixed near the left end of each outer tube 19, A right inner tube plate 9 is fixed near the right end of each of the outer tubes 19, an intermediate support tube plate 8 is fixed in the middle of each of the outer tubes 19, and a left end blocking plate of the outer tube is fixed on the left end of the outer tube 19. 29. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com