Method for producing sulfur dioxide from calcium sulfate and sulfur

A technology of sulfur dioxide and calcium sulfate, used in chemical instruments and methods, cement production, sulfur compounds, etc., can solve the problems of poor stability, difficult to achieve, poor heat transfer effect, and affecting the complete combustion of fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

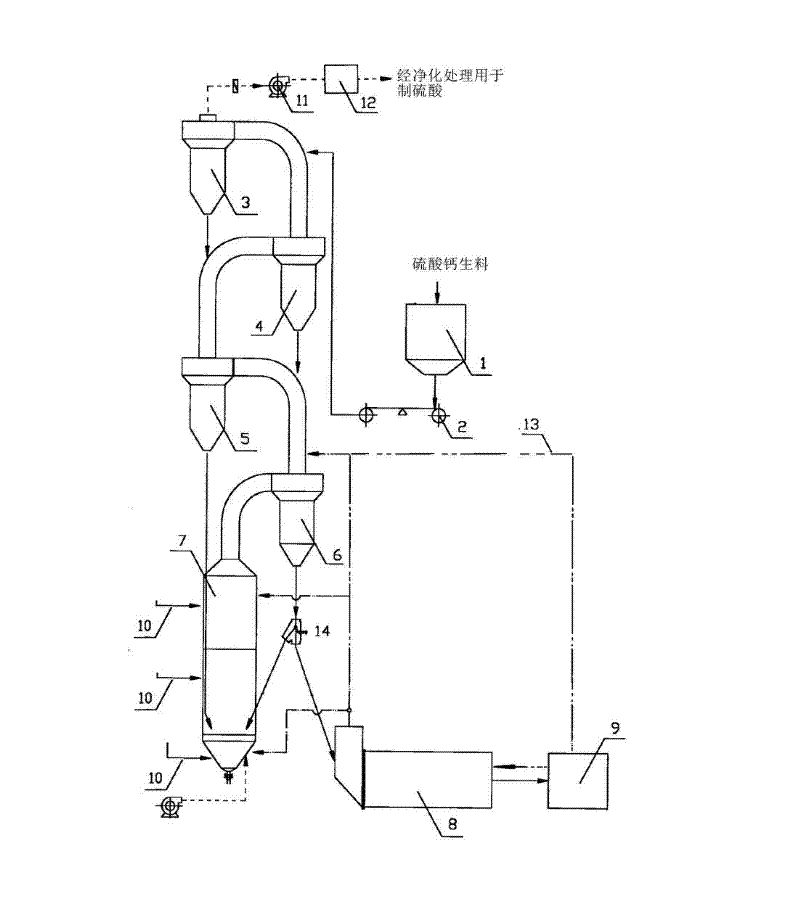

[0022] as attached figure 1 As shown, the phosphogypsum piled up in the slag yard obtained in the production of wet-process phosphoric acid, such as phosphogypsum containing 9-13% of external moisture, is added to the rotary hammer dryer and crusher commonly used in clinker firing in cement plants. The hot flue gas is subjected to heat exchange, dried into hemihydrate gypsum, mixed with pyrite slag, bauxite, and fly ash, and prepared into three rate values: KH=0.86—0.98, SM=1.8—4.0, IM =1.0—3.5 The gypsum raw meal is stored in the silo 1, the gypsum raw meal is measured by the weighing scale 2 and enters the four-stage cyclone preheater 3-6, and exchanges heat with the gas containing sulfur dioxide from the reduction furnace 7 and the rotary kiln 8, After being separated by the second cyclone preheater 5 counted from bottom to top, the material temperature rises to 600-950°C and enters the reduction furnace 7. The liquid sulfur is sprayed into the reduction furnace from the ...

Embodiment 2

[0032] When it is necessary to increase the reduction rate and heat capacity of calcium sulfate in the reduction furnace to improve the stability of the reduction system, the calcium sulfide and unreacted calcium sulfate mixture separated by the cyclone preheater 6 can be divided into two parts by the distributor 14. Part, wherein 50-70% of the material enters the reduction furnace, and the other 50-30% of the material enters in the rotary kiln, and the others are the same as the implementation example 1.

Embodiment 3

[0034] When using anhydrite as a raw material, because the anhydrite has less water content, it does not need to be dried, and it can be directly mixed and ground with the calibration raw material to obtain a gypsum raw meal, which is added to the system of Example 1. At this time, due to the total The moisture is low, in order to reduce the gas temperature of the cyclone preheater and improve the heat utilization rate, the number of stages of the cyclone preheater can be increased to 5-6. Others are the same as implementation example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com