Desulfurize flue gas waste heat recovery system used in fire coal electric generating set

A flue gas waste heat and recovery system technology, applied in the direction of reducing greenhouse gases, climate sustainability, combustion technology mitigation, etc., can solve the problems of increased resistance loss and water consumption of desulfurization towers, subsequent flues and chimneys, etc., and achieve sewage Reduced emissions and treatment costs, reduced discharge of saturated water vapor, and the effects of overcoming wear and sticking clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

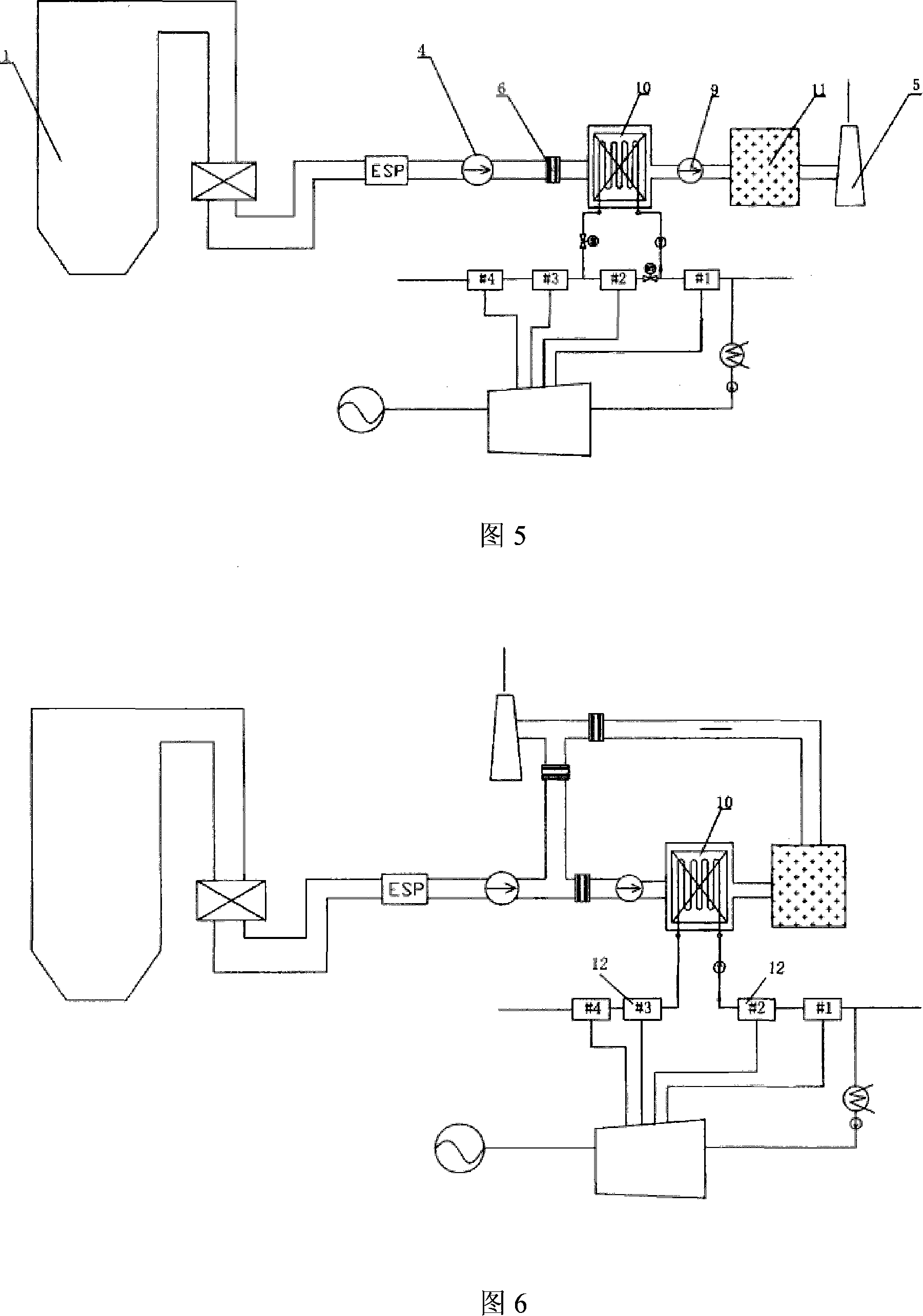

[0038] As shown in FIG. 3 , it is a schematic diagram of the system structure of the first specific embodiment of the generating set applying the present invention. The flue gas inlet of the desulfurization flue gas waste heat recovery system of the present invention is connected through the outlet of the induced draft fan 4 of the boiler device 1 in the coal-fired generating set; the flue gas outlet of the desulfurization flue gas waste heat recovery system is connected through the inlet of the desulfurization absorption tower 11 Meanwhile, in order to control the flue gas flow direction and overcome the system resistance, the desulfurization system, in addition to the desulfurization absorption tower 11 and the chimney 5, is additionally equipped with a desulfurization flue gas inlet baffle 6 and a booster fan 9, and the desulfurization absorption tower 11 and the chimney 5 A desulfurization flue gas outlet baffle 8 is also arranged between them.

[0039] The special feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com