Active carbon horizontal converter

A kind of activated carbon, horizontal technology, applied in the field of activated carbon production equipment, can solve the problems of uneven heating of materials, low heat energy utilization rate, long activation time, etc., and achieve good activation effect, high heat energy utilization rate and short activation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

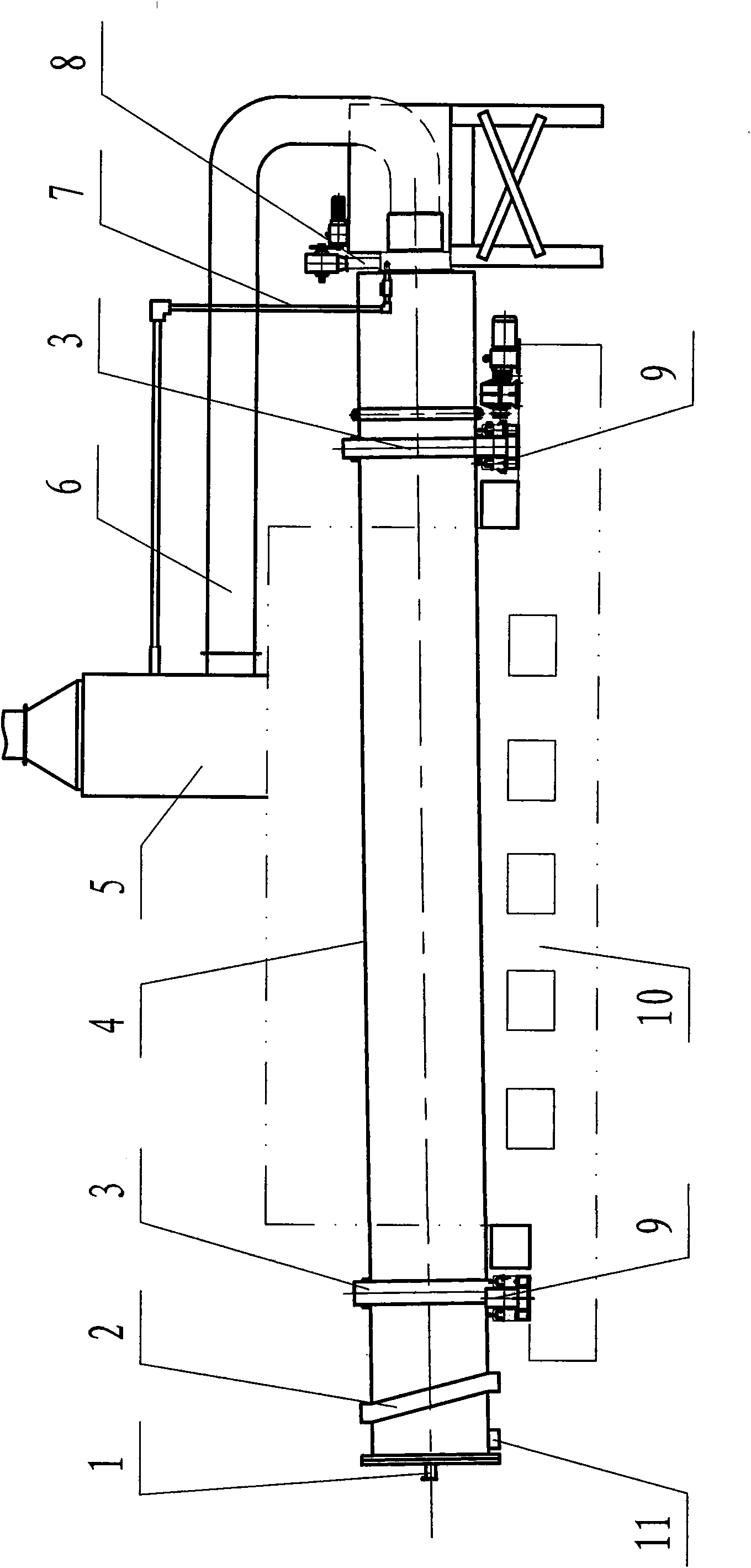

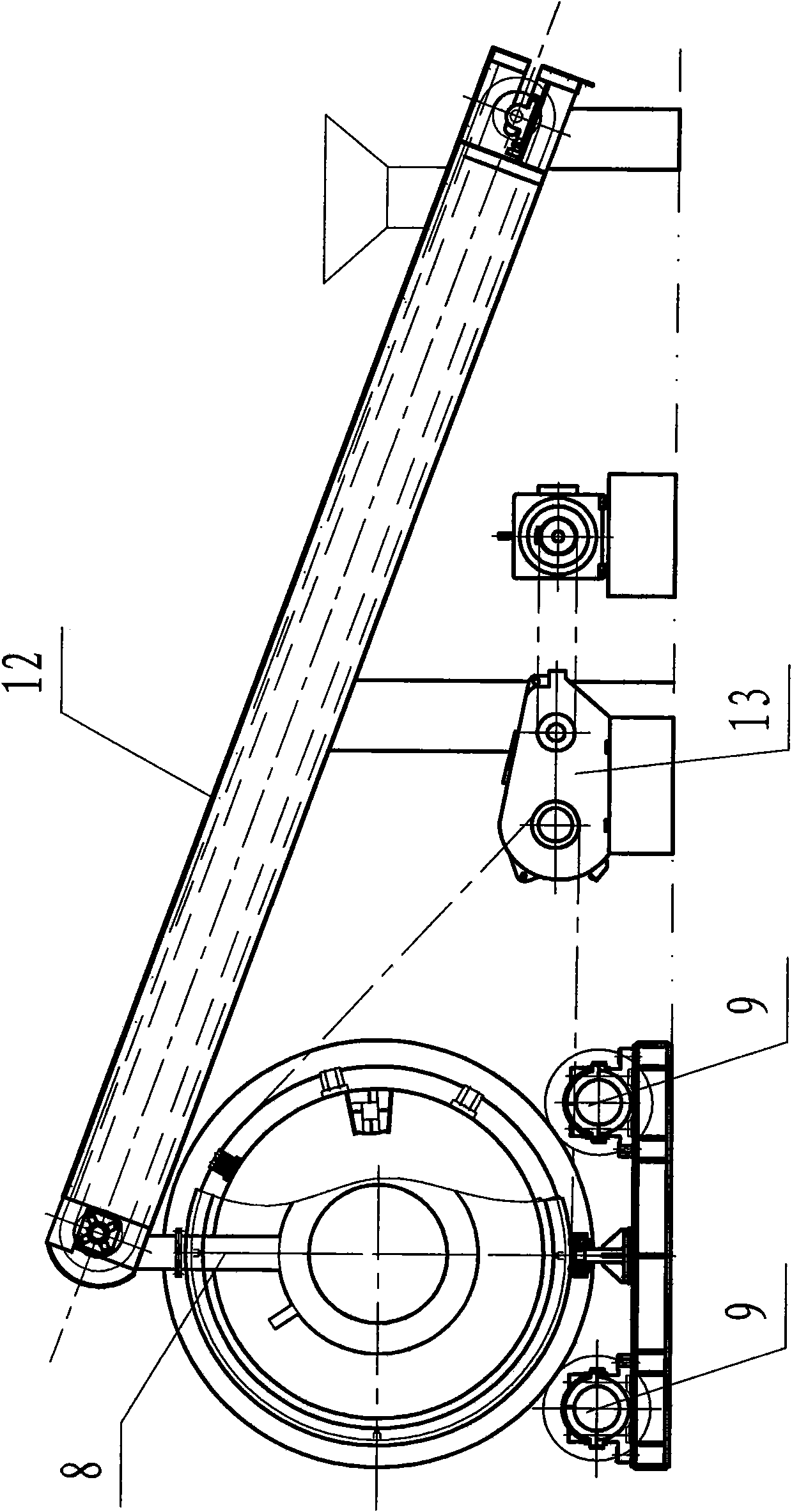

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a driving mechanism 13, a feeding mechanism 12, an outer cylinder 4, a gas distribution pipe 1, an exhaust pipe 24, a flue 6, a steam generator 5, and a steam pipe 7, and the outer cylinder 4 is placed on the The idler roller assembly 9 rotates around the axis under the drive of the drive mechanism 13 .

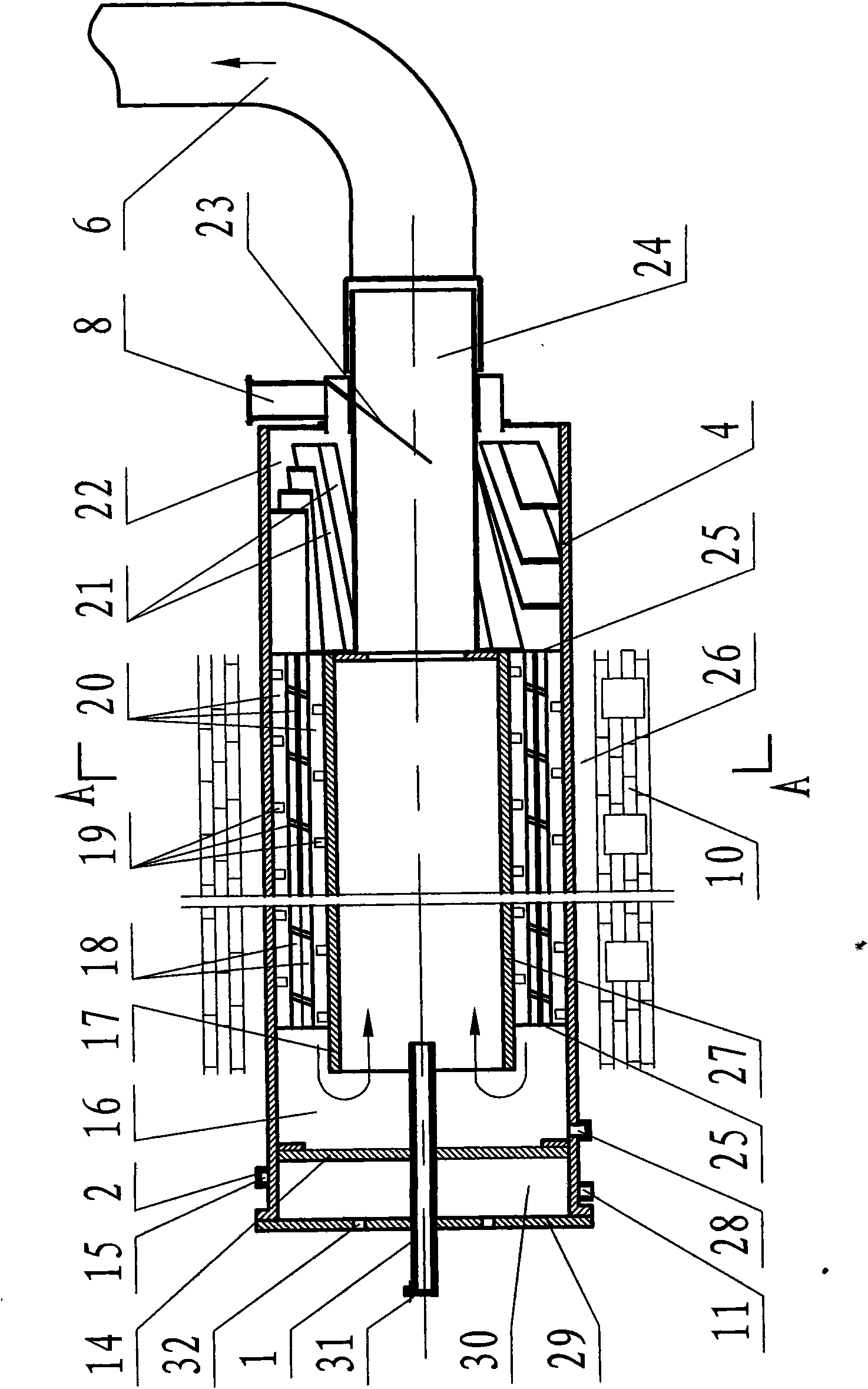

[0016] Such as image 3 , Figure 4 , Figure 5 As shown, an inner cylinder 27 is provided in the outer cylinder 4, and the inner cylinder 27 is welded in the outer cylinder 4 with a vertical plate 25, and the vertical plate 25 separates at least three independent material passages 18 (commonly known in the industry) between the outer cylinder 4 and the inner cylinder 27. Product road), all be welded with copying plate in each material passage 18, be used for copying and turning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com