Rankine cycle power generation system capable of realizing efficient utilization of heat energy

A Rankine cycle and power generation system technology, applied in energy applications and new energy applications, can solve the problems of low thermal energy utilization rate and difficulty in popularization, and achieve the effect of improving thermal energy utilization rate and thermoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

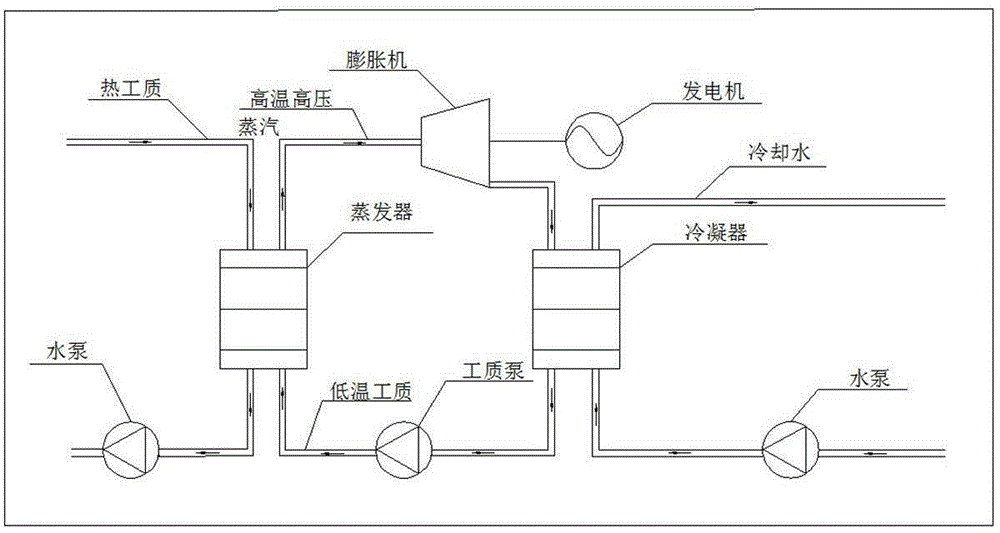

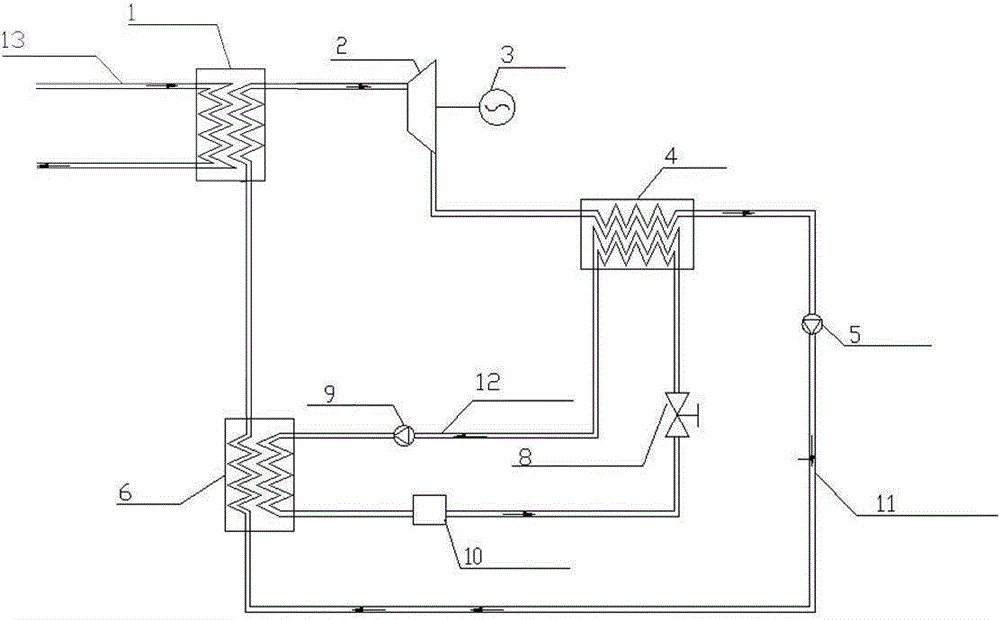

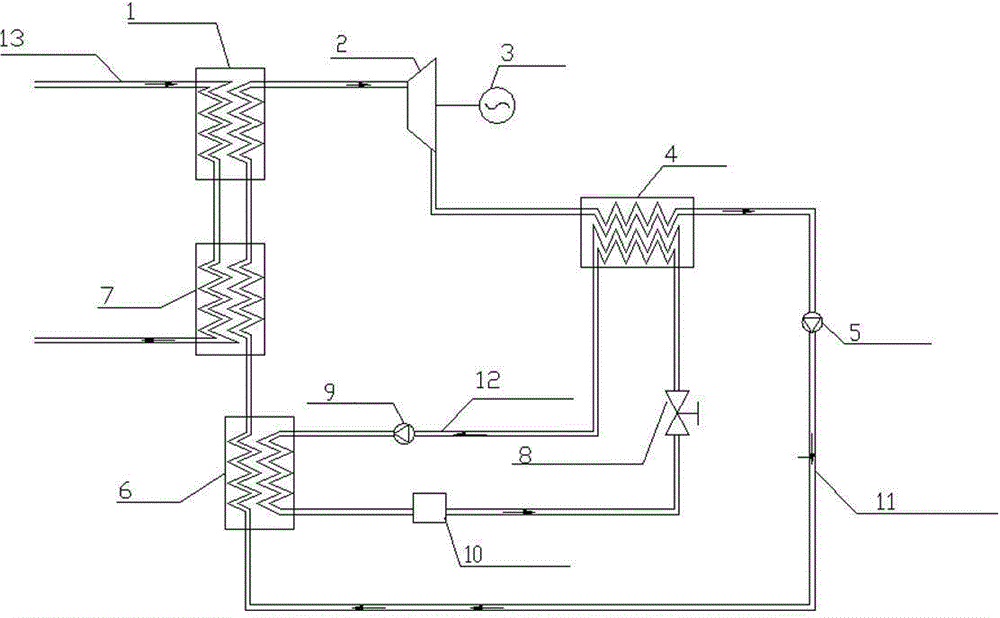

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

[0030] The present invention is a Rankine cycle power generation system that can realize high-efficiency utilization of heat energy, and is characterized in that: the system is a Rankine cycle power generation system with a reverse Carnot cycle subsystem, mainly composed of a steam generator 1, an expansion power machine 2, The generator 3, the condenser 4, the working medium pump 5, the regenerator 6, the working medium 11 and the working medium pipeline are composed together; the regenerator 6 is installed between the steam generator 1 and the working medium pump 5, and the Rankine cycle The flow path of the working medium 11 is connected as follows: the steam generator 1 is connected to the expansion power machine 2, the expansion power machine 2 is connected to the condenser 4, the condenser 4 is connected to the working medium pump 5, the working medium pump 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com