Nano-liquid electrostatic atomization and thermoelectric heat pipe integrated trace lubrication grinding device

An electrostatic atomization, nanofluid technology, applied in grinding/polishing safety devices, grinding/polishing equipment, abrasives, etc., to achieve the effect of improving cooling effect, reducing grinding temperature, and enhancing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

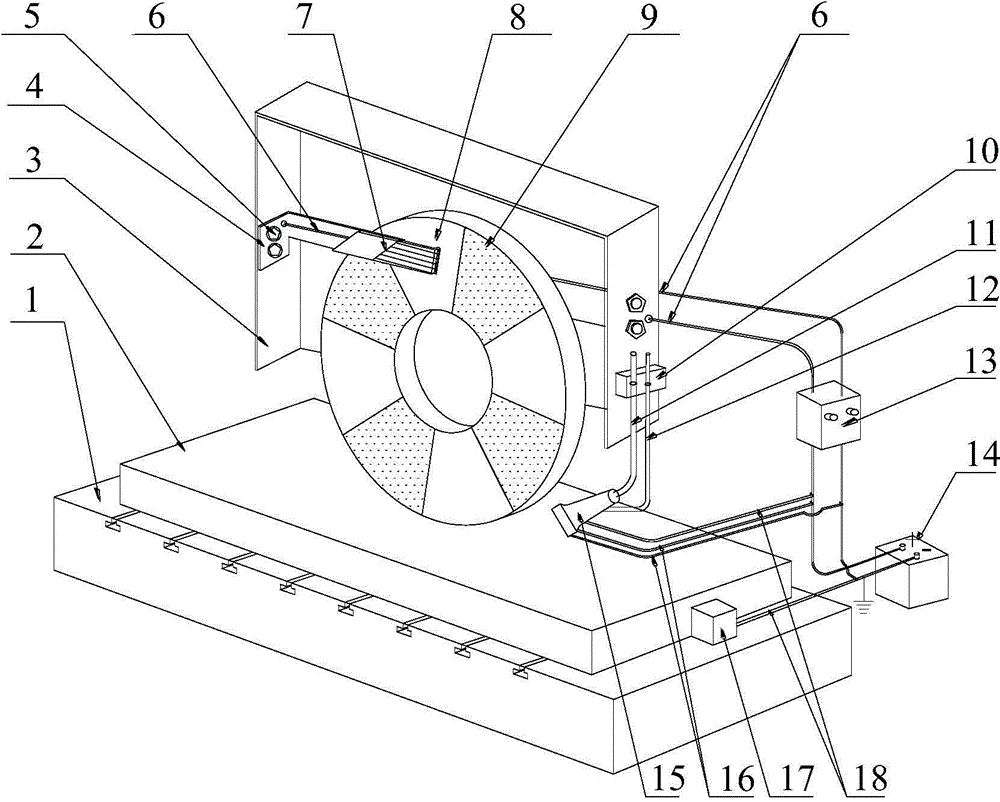

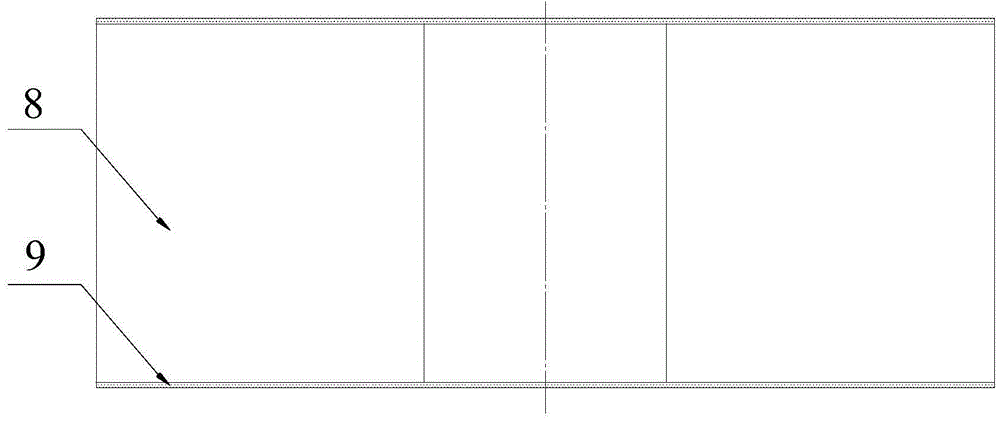

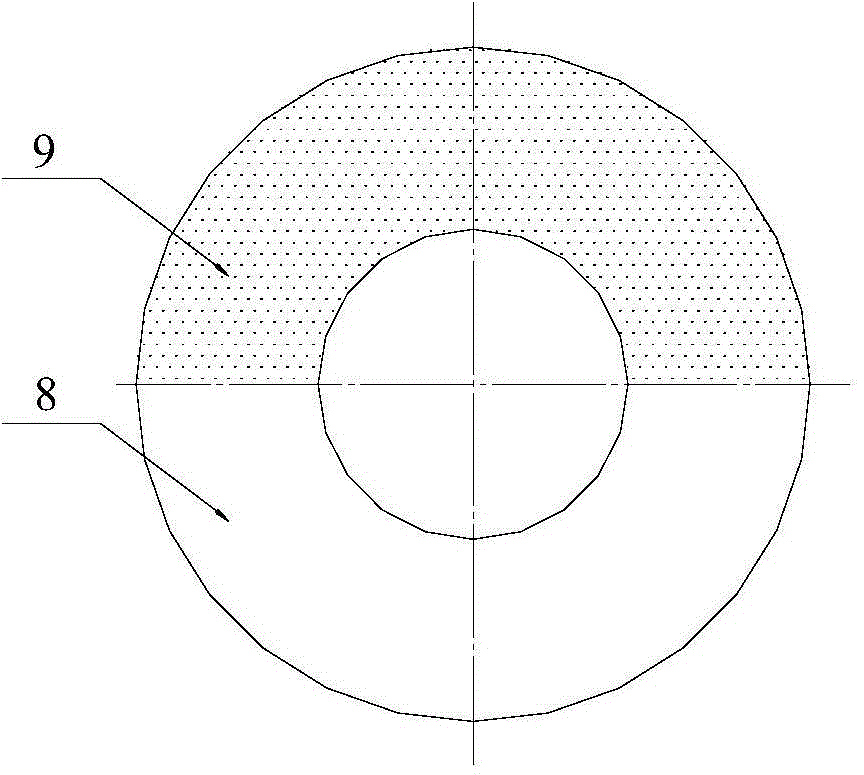

[0062] The first embodiment of the present invention is figure 1 , figure 2 , Figure 6a , b and Figure 7 as well as Figures 11 to 22 As shown, it is about nano-particle jet micro-lubrication electrostatic atomization and electric card refrigeration grinding device. The electrostatic atomization and electric card refrigeration grinding device includes a heat pipe grinding wheel 8 covered with electric card film material 9 on both sides, nanofluid added with electric card nano powder material, and a high-voltage DC electrostatic generator and a magnetic field forming device. Electric card refrigeration and electrostatic atomization combined nozzle 15 under the magnetically enhanced electric field; the ferroelectric film covering the surface of both sides of the heat pipe grinding wheel absorbs heat in the grinding area by the electric card effect,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com