Water distillation system

A technology of distillation system and evaporator, which is applied in the field of water distillation system and can solve the problems of low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

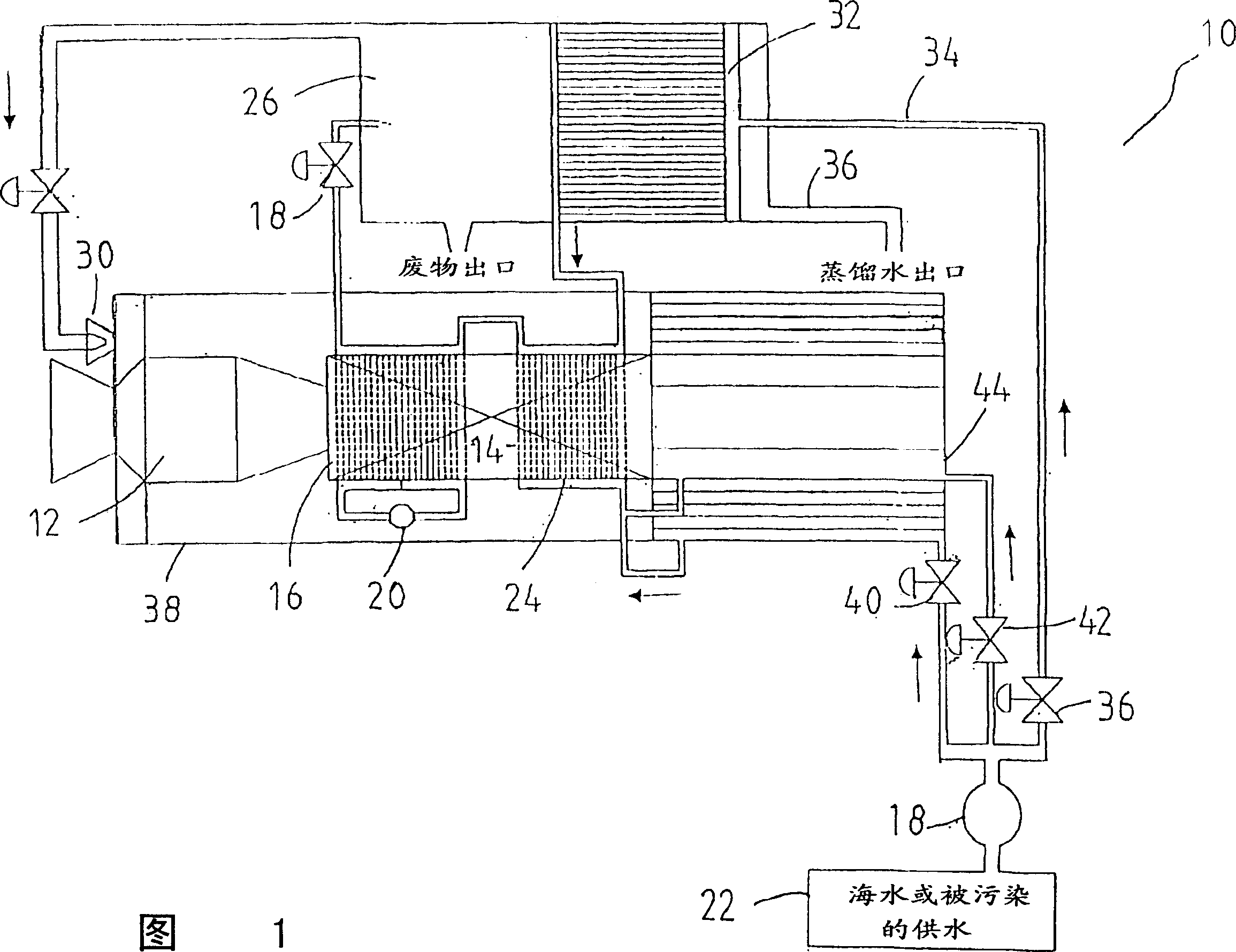

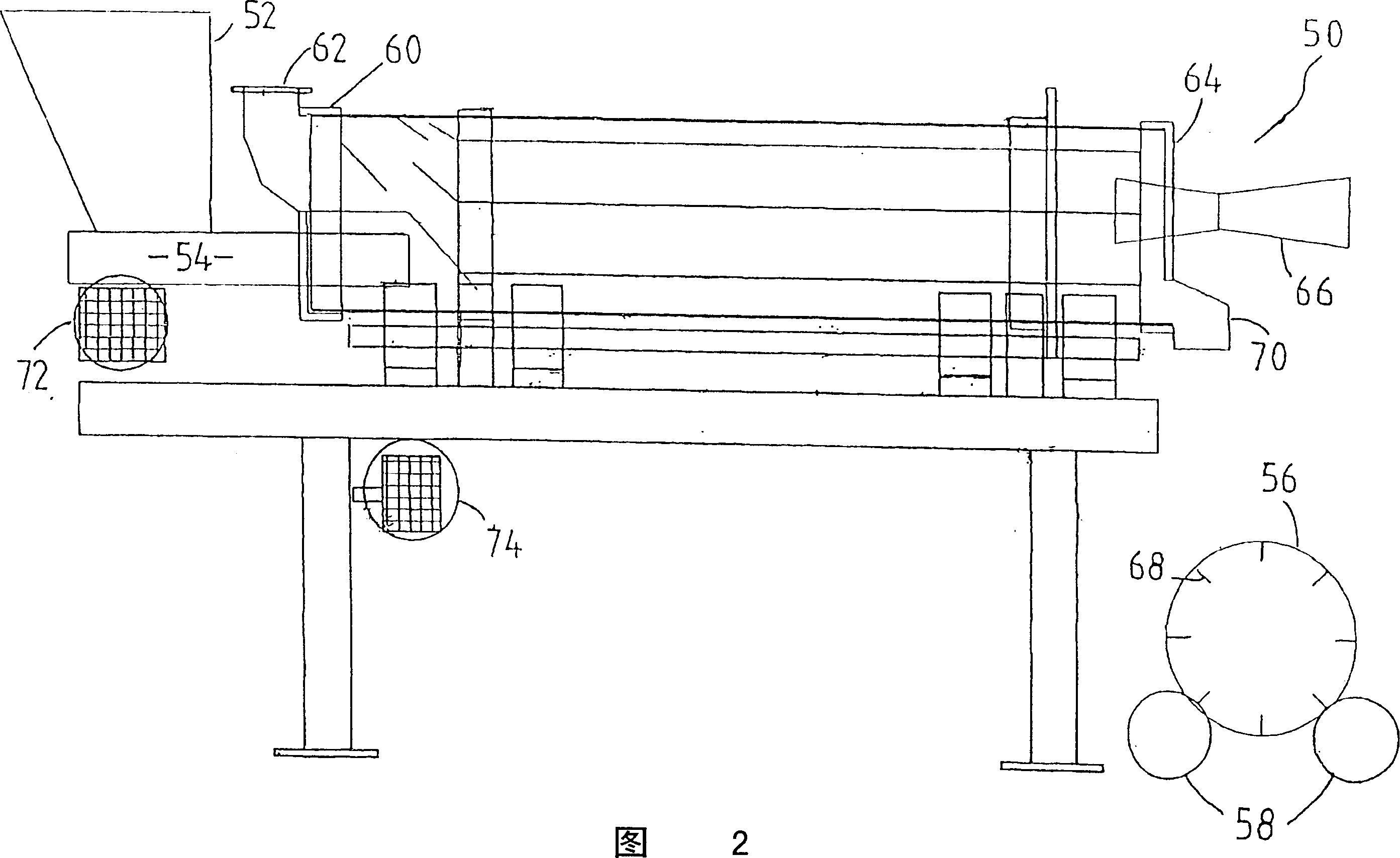

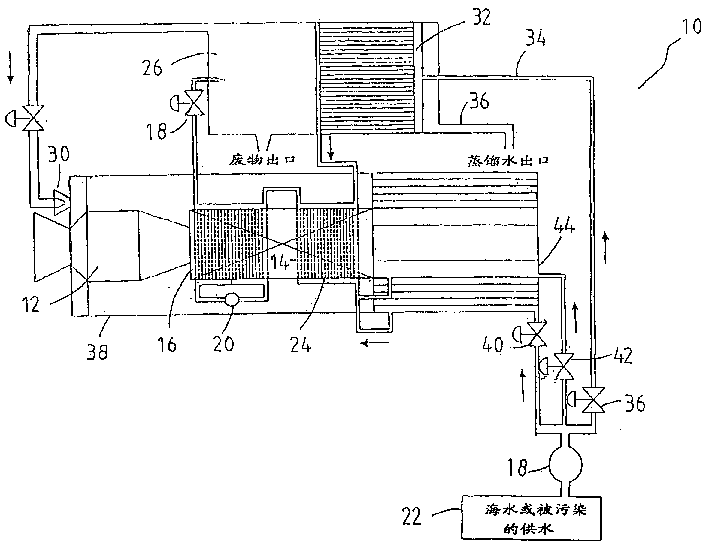

[0053] In the water distillation system 10 shown in FIG. 1 , the heating engine 12 is an RB 211 aircraft engine, and the engine 12 is fueled by kerosene. When such engines exceed the manufacturer's recommended flight hours, they can still be used as heat engines in high-volume retorts, meaning those on the order of 40-50 kiloliters / hour. The engine can be tuned to operate as a heat engine rather than providing propulsion. Under steady conditions and using kerosene as fuel, the engine temperature can reach 1150°C. Exhaust gases may be discharged into horizontal ducts 14 where the burned gases at about 650°C are impinged onto the stainless steel cross tubes of the main heat exchanger 16, which are supplied by a pump 18 with circulating feed water. A recirculating pump 20 increases the pressure of the water, thereby raising the boiling point. The water temperature can rise to about 165°C.

[0054] Pump 18 provides a constant supply of water from a seawater tank 22 . Seawater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com