Method for cooling heating element and recovering energy of heating element

A heating element and energy technology, applied in the electronic field, can solve the problems of large heat sink space, small size, low efficiency, etc., and achieve the effect of extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The following experiment will illustrate that the present invention actively cools the heating element and recycles the energy to verify that the present invention does not need to consume electric energy to actively cool the heating element, and convert heat energy into electrical energy to charge the battery during the cooling process. , to recover energy, the greater the work done by thermoelectric materials or thermoelectric devices, the more heat absorbed from the heating element. Advantages:

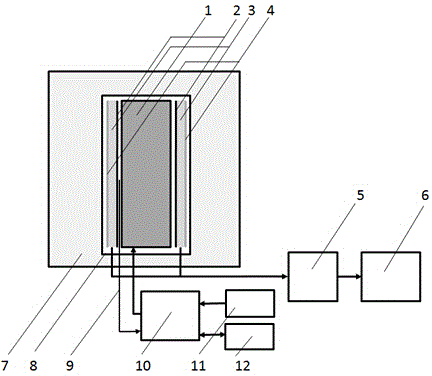

[0020] Such as image 3 As shown, it is a schematic structural diagram of an embodiment of the present invention, including a heating element 1, a high temperature end 2 of a thermoelectric device, a thermoelectric device 3, a low temperature end 4 of a thermoelectric device, a voltage stabilizing module 5, a rechargeable battery 6, and a constant temperature water bath 7 , a sealing film 8, a thermocouple 9, an intelligent temperature controller 10, a 220 volt AC power supp...

Embodiment 2

[0025] Embodiment 2 adopts the structural diagram in Embodiment 1 of the present invention (such as image 3 As shown), only the temperature control method of the heating element 1 by the intelligent temperature controller 10 is changed.

[0026] The temperature of the heating element 1 is kept constant at 75.0°C by the intelligent temperature controller 10, and the heating power percentage output by the intelligent temperature controller 10 to the heating element 1 is measured. In the measurement process, firstly, the thermoelectric circuit is opened for about 10 minutes, and the thermoelectric device 3 does not perform work; then the thermoelectric circuit is closed for about 10 minutes, and the thermoelectric device 3 performs work, and the current of the thermoelectric circuit is measured; then, the thermoelectric circuit is opened for about 10 minutes, and the thermoelectric device 3 No work is done; when the obtained heating element is at a constant temperature of 75.0°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com