Wafer angular deviation automatic method based on vision

An automatic correction and angle deviation technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of radius direction error at the center of the circle, achieve high reliability, improve processing efficiency, and promote intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

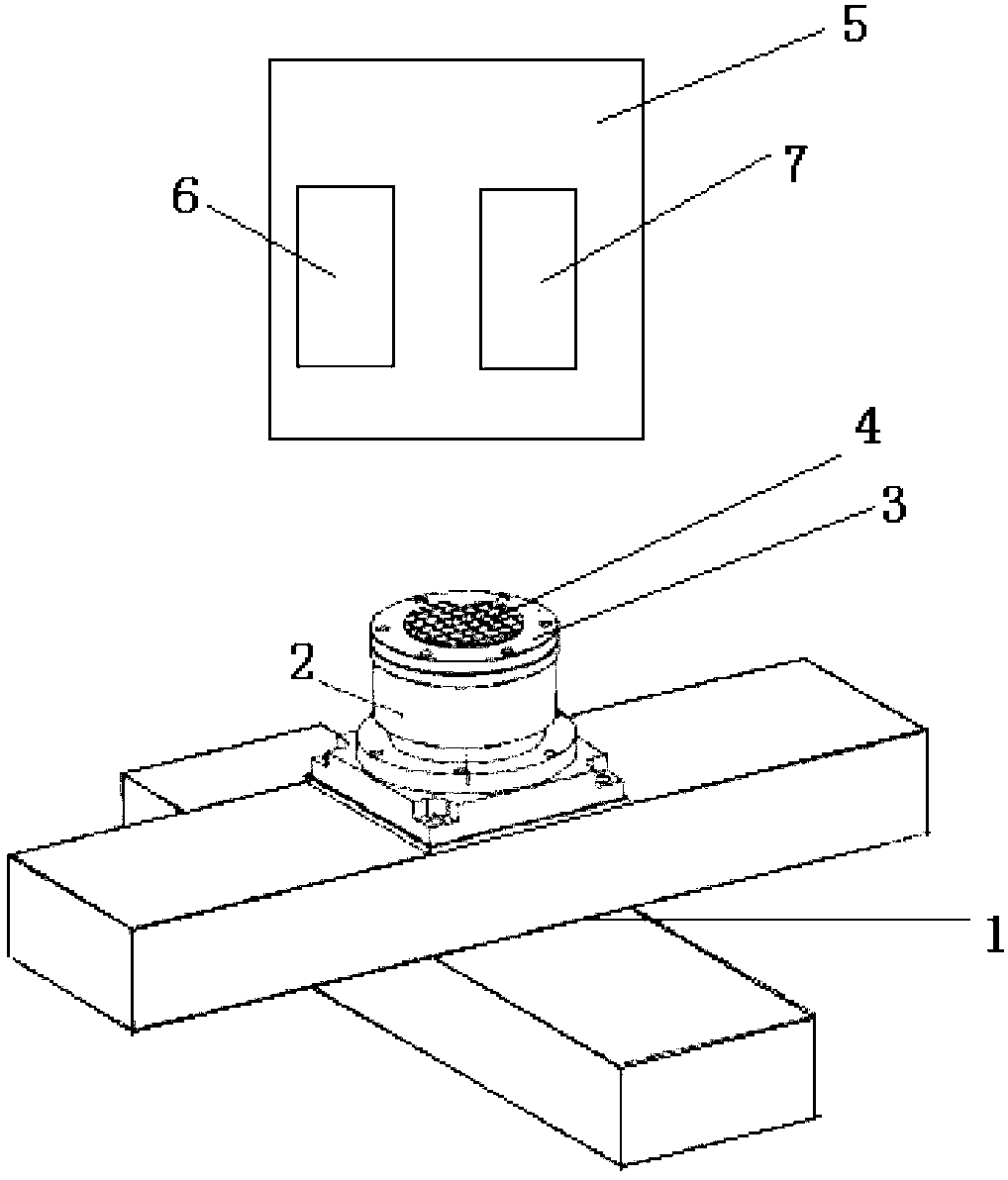

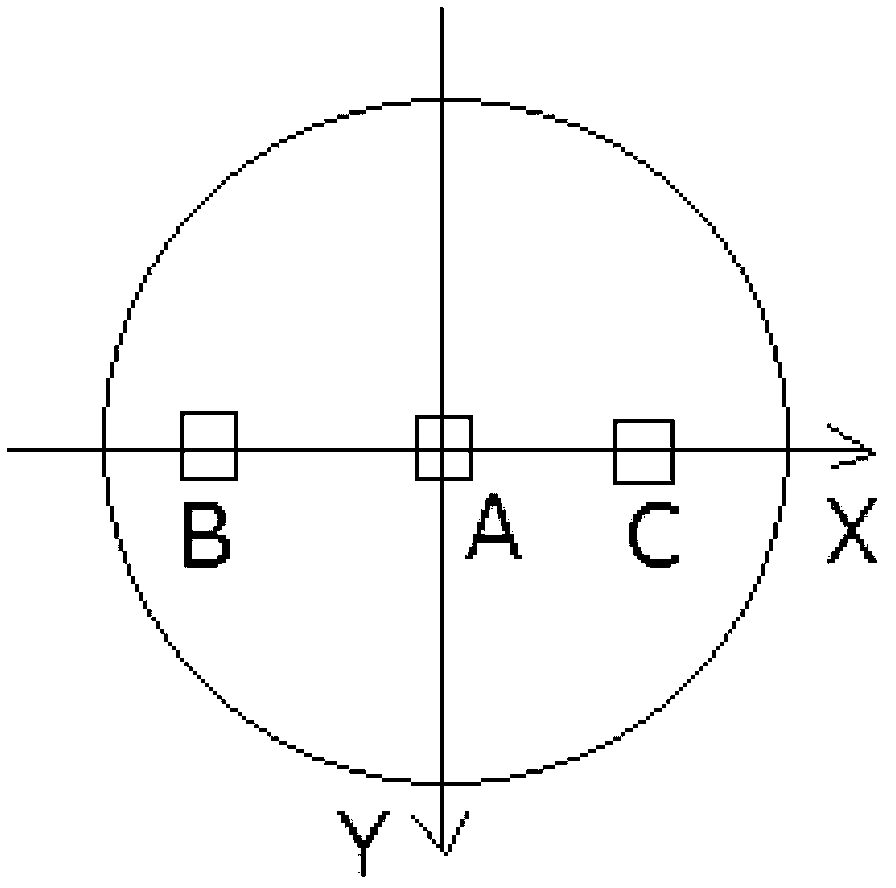

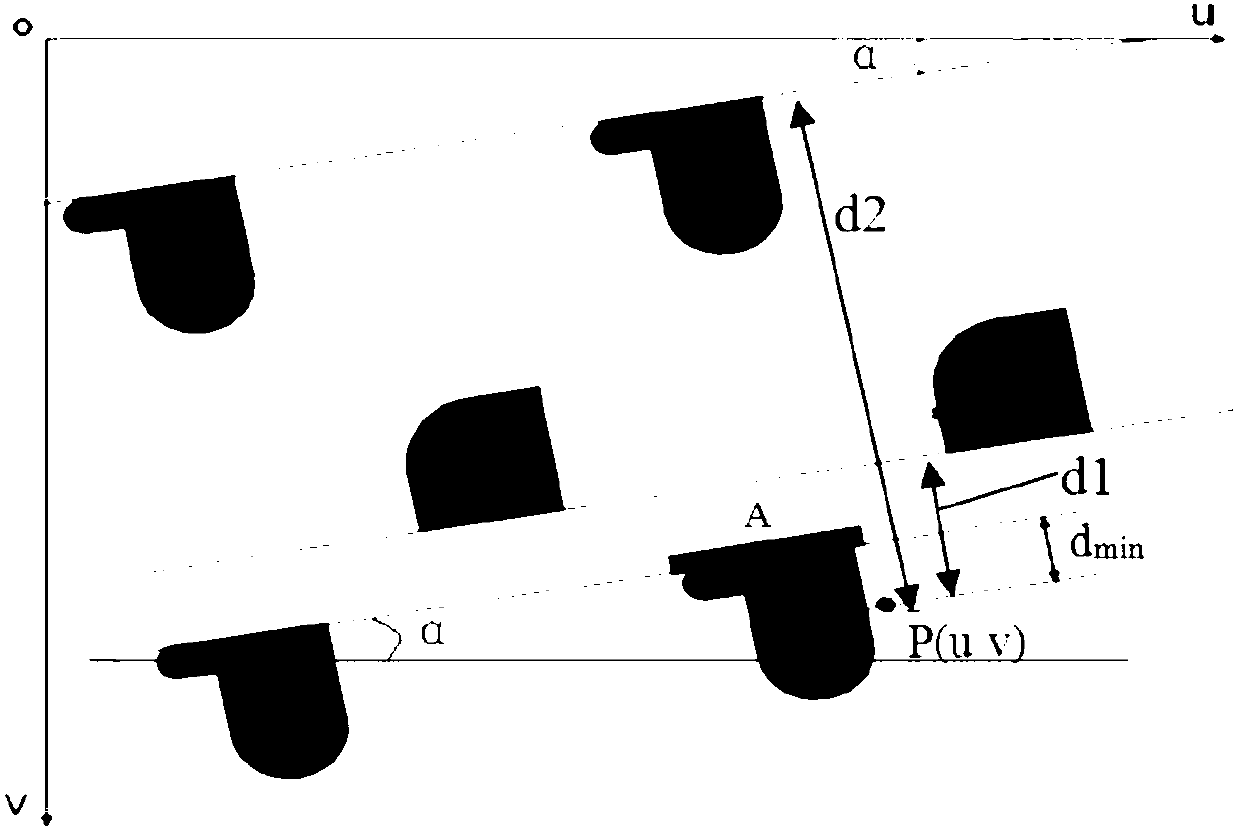

[0029] see figure 1 As shown, the method of the present invention arranges the wafer 4 on the adsorption disk 3 of the four-axis CNC machine tool platform system, and the wafer 4 photographed by the microscopic camera 6 of the four-axis CNC machine tool platform system through the Hough transformation in the OpenCV computer vision library The image is detected and positioned to determine the feature line and feature point position on the edge of the chip pin on the wafer 4, and the position of the wafer 4 is adjusted according to the angle formed between the feature line and the X or Y axis direction of the four-axis CNC machine platform ;

[0030] The four-axis CNC machine tool platform system includes an X / Y-axis motion platform 1. The X / Y-axis motion platform 1 has high precision, repeat positioning accuracy can reach 0.5um, large bearing capacity, precise orientation, strong controllability, and stable system , which is used to realize the scribing movement on the two-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com