Composite and adjustable hydration heat cement-based material and application thereof

A cement-based material and heat of hydration technology, applied in the field of cement control materials, can solve the problems of reducing the maximum rate of cement hydration, unfavorable waste gas and waste residue treatment, and limited hydration control performance, so as to reduce the heat release of cement hydration Speed peak, reduce cracking phenomenon, realize the effect of circular economy and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

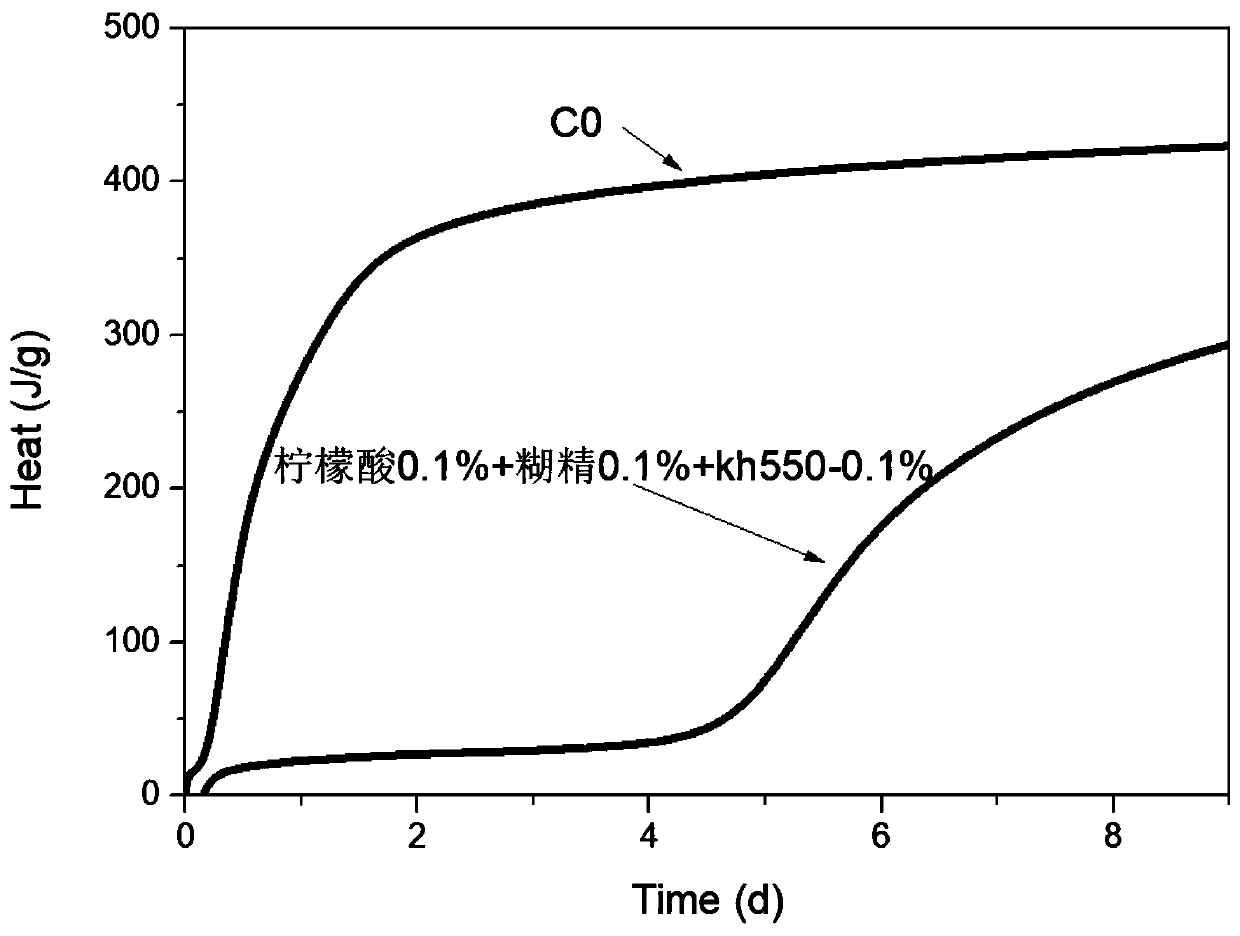

[0028] This embodiment provides the preparation method of the adjustable hydration heat composite cement-based material, including the following steps:

[0029] (1) Add a certain proportion of cross-linking agent and organic acid into water to fully dissolve and mix evenly to obtain a mixed solvent.

[0030] (2) A certain proportion of starch-based polymeric organic matter and Portland cement powder are fully mixed to obtain a mixed powder.

[0031] (3) Mix the above mixed solvent and mixed powder, stir at a high speed for 120s, weigh an appropriate amount of slurry, and conduct a hydration heat test.

[0032] Wherein, in the step (1), the crosslinking agent and the organic acid are respectively kh550 silane coupling agent and citric acid, and the admixture mass is based on the mass percentage of Portland cement, and the content is 0.05%.

[0033] Wherein, in the step (2), the starch-based macromolecular organic matter is dextrin (12300 g / mol), and the added mass is based on ...

Embodiment 2

[0035] This embodiment provides the preparation method of the adjustable hydration heat composite cement-based material, including the following steps:

[0036] (1) Add a certain proportion of cross-linking agent and organic acid into water to fully dissolve and mix evenly to obtain a mixed solvent.

[0037] (2) A certain proportion of starch-based polymeric organic matter and Portland cement powder are fully mixed to obtain a mixed powder.

[0038] (3) Mix the above mixed solvent and mixed powder, stir at a high speed for 120s, weigh an appropriate amount of slurry, and conduct a hydration heat test.

[0039] Wherein, in the step (1), the crosslinking agent and the organic acid are respectively kh550 silane coupling agent and citric acid, and the admixture mass is based on the mass percentage of Portland cement, and the content is 0.1%.

[0040] Wherein, in step (2), the starch-based macromolecular organic matter is dextrin (12300 g / mol), and the added mass is based on the m...

Embodiment 3

[0042] This embodiment provides the preparation method of the adjustable hydration heat composite cement-based material, including the following steps:

[0043] (1) Add a certain proportion of cross-linking agent and organic acid into water to fully dissolve and mix evenly to obtain a mixed solvent.

[0044] (2) fully mixing a certain proportion of starch-based polymeric organic matter and Portland cement powder to obtain a mixed powder;

[0045] (3) Mix the above mixed solvent and mixed powder, stir at a high speed for 120s, weigh an appropriate amount of slurry, and conduct a hydration heat test.

[0046] Wherein, in the step (1), the crosslinking agent and the organic acid are respectively kh550 silane coupling agent and citric acid, and the admixture mass is based on the mass percentage of Portland cement, and the content is 0.1%.

[0047] Wherein, in the step (2), the starch-based macromolecular organic matter is dextrin (12300 g / mol), and the added mass is based on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com