Lcd device and its manufacture method

A technology of a liquid crystal display device and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of weak anchoring force of liquid crystal molecules, inferior anchoring force compared to contact alignment methods, difficulties in implementation, etc., and achieve good liquid crystal response Speed, good liquid crystal alignment effect, and the effect of optimizing the yield of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

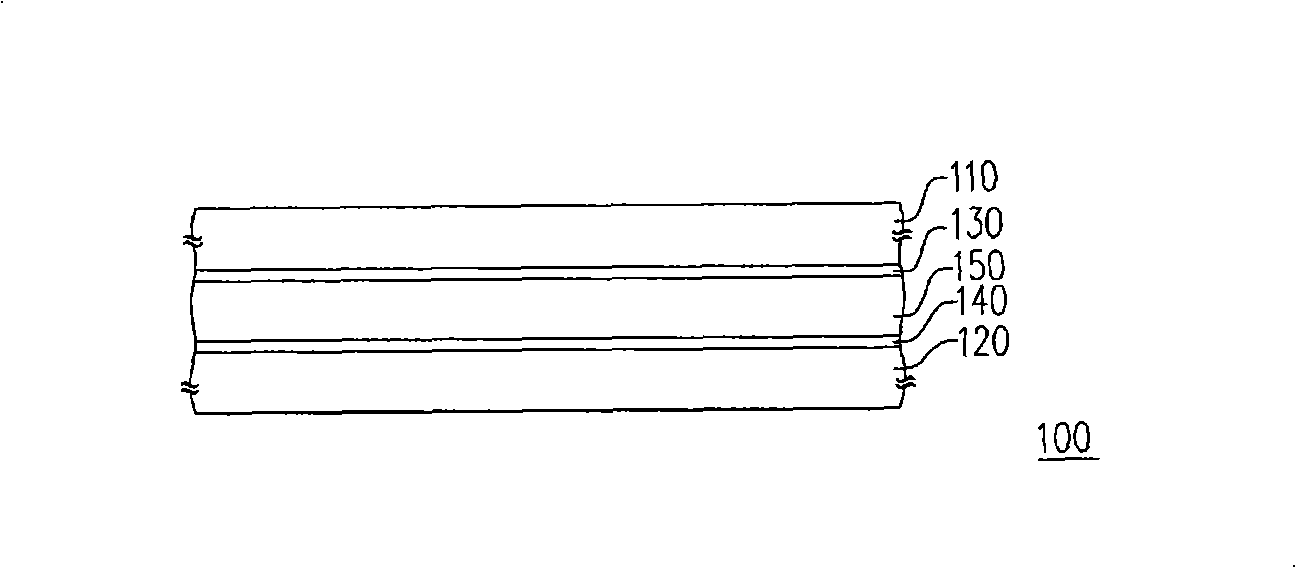

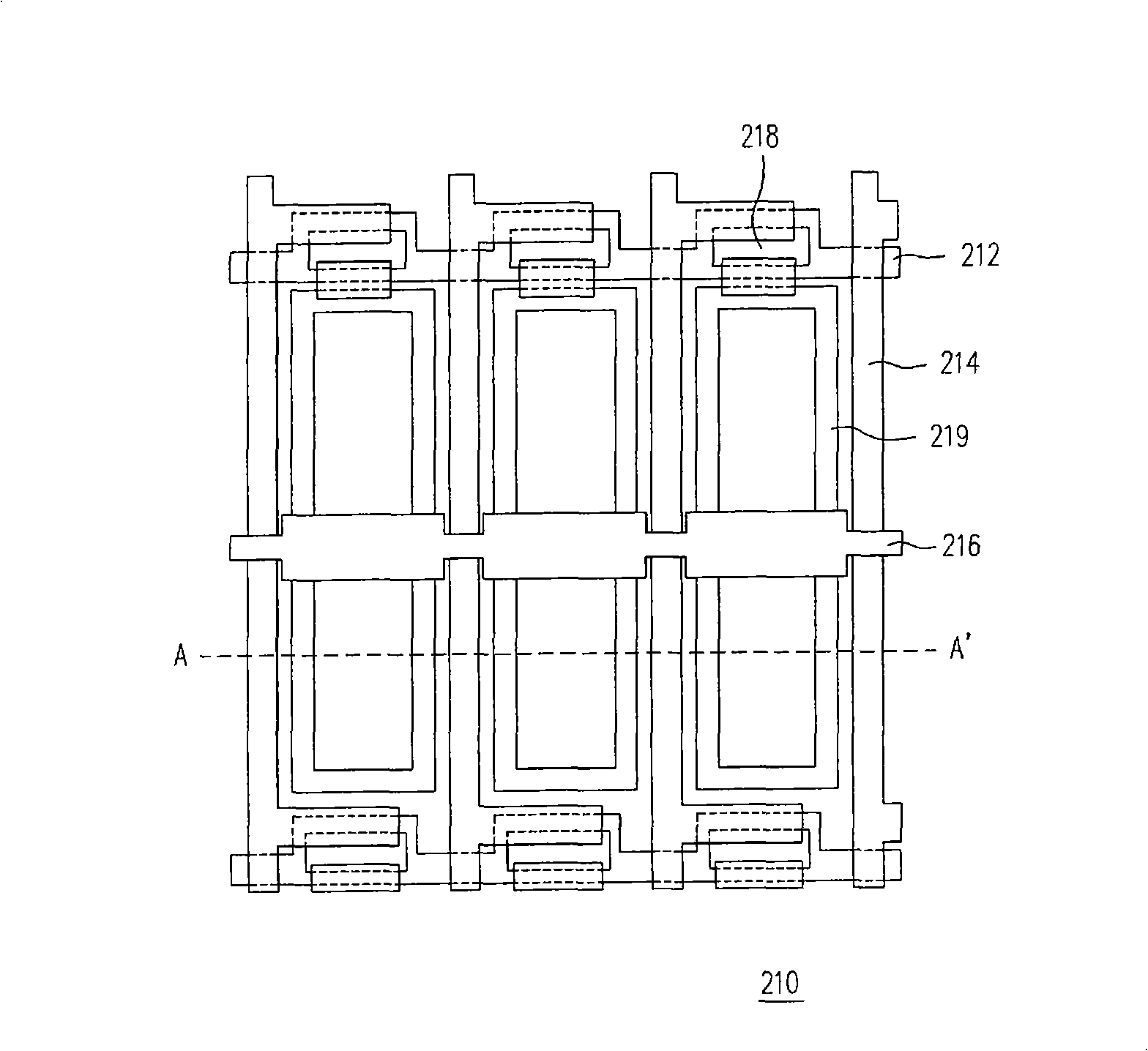

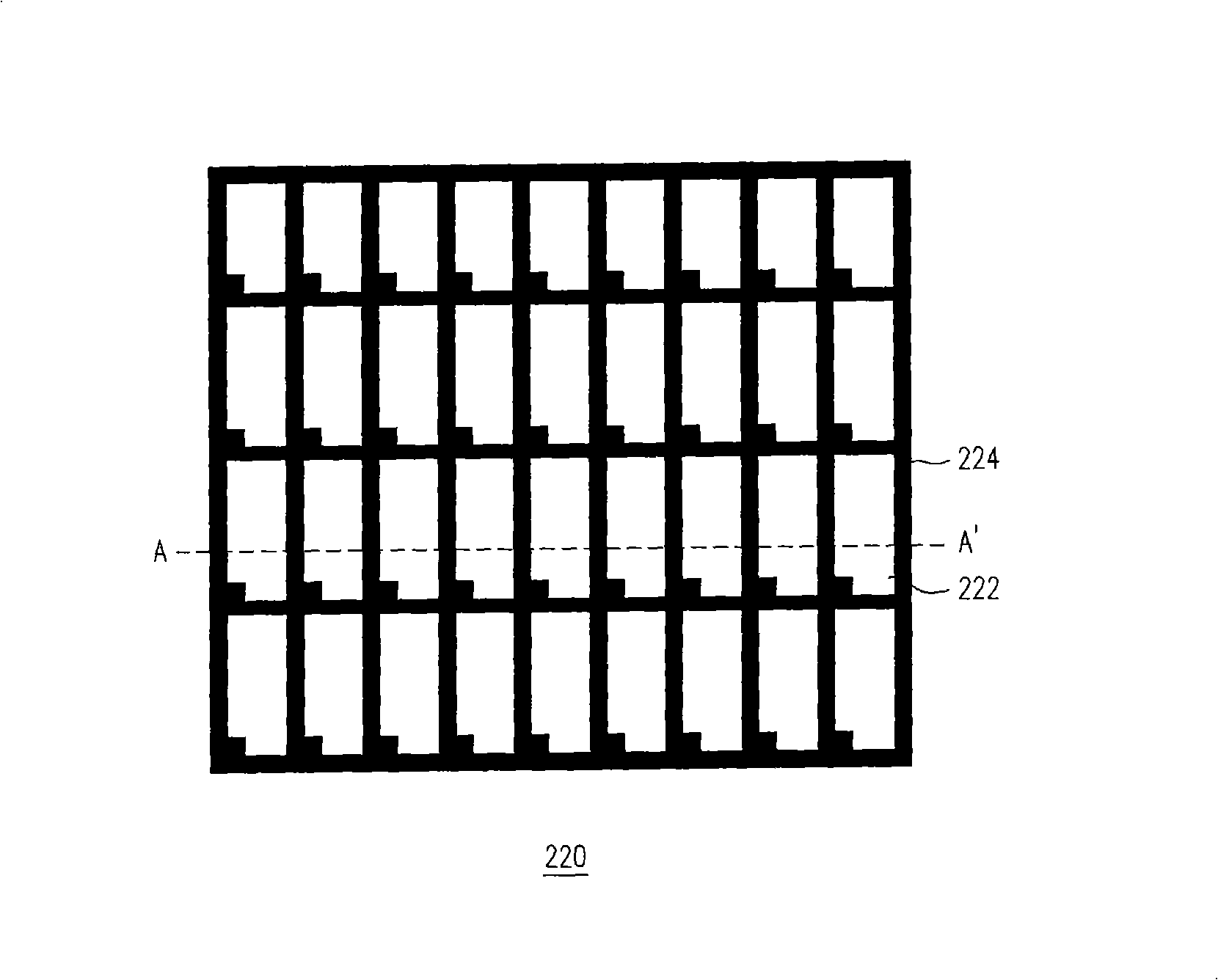

[0065] The liquid crystal display device proposed by the present invention mainly includes components such as a substrate, an opposing substrate, a liquid crystal layer, a non-contact alignment layer, and a liquid crystal stabilizing layer, wherein the substrate is, for example, a thin film transistor array substrate, and the opposing substrate is, for example, a color filter substrate The liquid crystal layer contains at least one liquid crystal molecule and is arranged between the thin film transistor array substrate and the color filter substrate. The liquid crystal display device of the present invention can be a twisted nematic liquid crystal display device (Twist Nematic LCD, TN-LCD), or a vertical alignment liquid crystal display device (Vertical Alignment LCD, VA-LCD) or other types of liquid crystal display devices , and with the different types of liquid crystal display devices, the types of liquid crystal molecules are also different, and the pre-tilt angle (pre-tilt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com