Seabed automatic anchoring device

An anchoring device and anchoring technology, used in anchoring arrangement, transportation and packaging, ship parts, etc., can solve the problem of low drilling efficiency, affecting the drilling force of the anchor, the amount of cutting and the maximum depth, drilling Slow speed and other problems to achieve the effect of improving drilling efficiency and drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

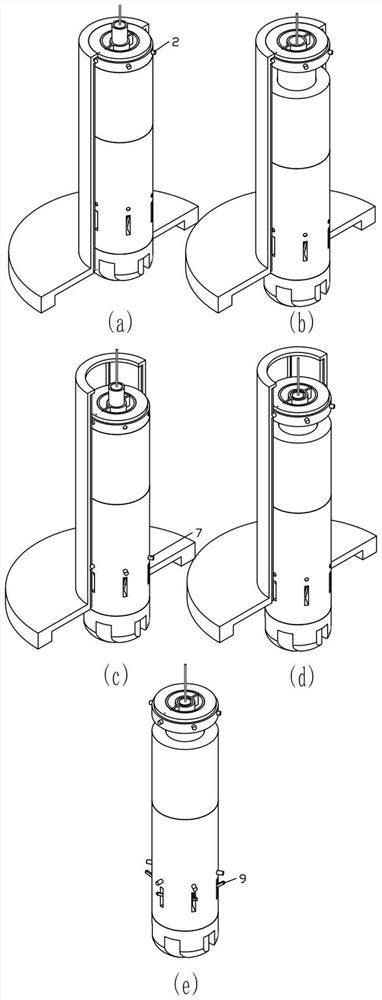

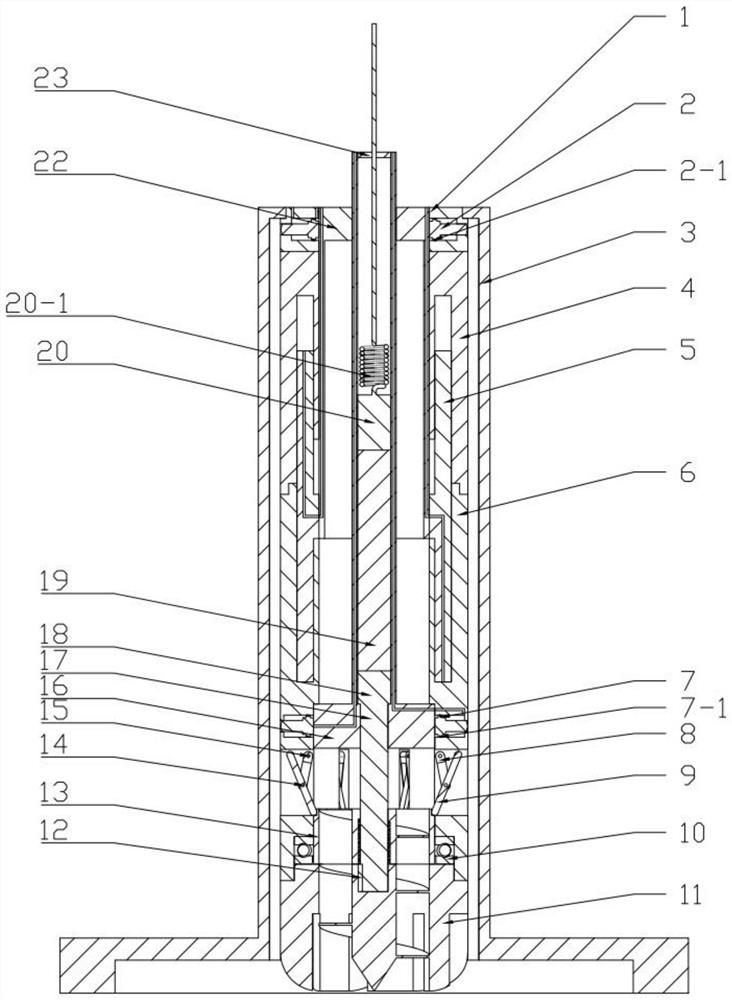

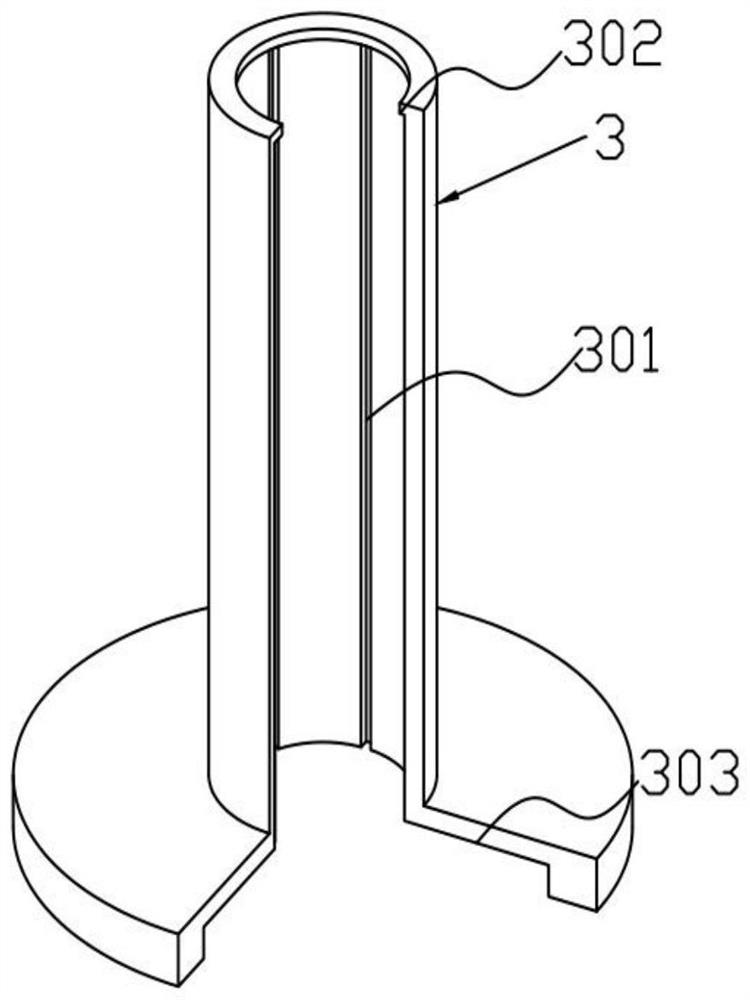

[0035]The invention relates to a seabed automatic anchoring device. The device consists of an external centralizing shell and an internal anchor. The internal anchor includes an upper part and a lower part. The upper part includes the anchoring mechanism I, and the lower part includes the advancing mechanism, anchoring mechanism II, drilling mechanism, and connecting rods. Mechanism; the outer centralizing shell is set outside the inner anchor, and there are six circumferentially evenly distributed slide grooves inside the outer centralizing shell for circumferentially positioning the internal anchor, and the upper part is provided with a limiting shoulder for axial positioning Internal anchor, the lower part is provided with a cavity for the accumulation of cuttings generated at the edge of the drill bit when drilling; the anchor mechanism Ⅰ of the anchor includes anchor sleeve, anchor block Ⅰ, sealing ring Ⅰ, connecting pipe , the sealing ring Ⅰ is installed on the anchor bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com