Method for improving cationized modification evenness of cotton fabrics

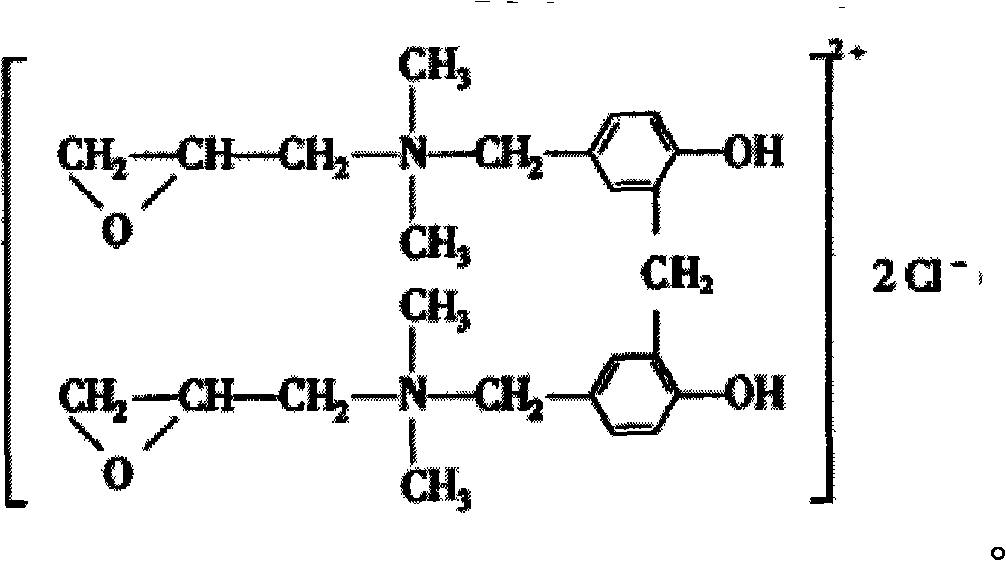

A technology for cationized modification of cotton fabrics, applied in the field of dyeing and finishing, can solve the problems of difficult diffusion of modifiers, uneven dyeing, uneven modification, etc., so as to reduce hydrolysis loss, improve dyeing uniformity, and solve the Effects of dyeing and penetrating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment selects pure cotton knitted fabric to carry out dyeing treatment, and concrete steps are as follows:

[0028] (1) Cationic modification

[0029] Modification liquid formula: the dosage of Glytac A is 4% (o.w.f.), the dosage of Pingpingjia O is 0.5% (o.w.f.), and the bath ratio is 1:15.

[0030] Modification process: at room temperature, put cotton fabric in the modified liquid, raise the temperature to 95°C at a rate of 1-2°C / min, and keep it warm for 20 minutes; then cool down the mixture system of cotton fabric and modified liquid to 30 ℃, wherein caustic soda is added to make the concentration of caustic soda in the solution reach 0.5g / L, react for 20 minutes, take out and wash with water.

[0031] (2) Dyeing with reactive dyes

[0032] Cotton fabrics treated with the above modified solution were dyed with reactive blue KN-R.

[0033] Dyeing liquid formula: dyestuff is equivalent to the weight percentage concentration (o.w.f.) of fabric is 2...

Embodiment 2

[0040] The present embodiment selects pure cotton knitted fabric to carry out dyeing treatment, and concrete steps are as follows:

[0041] (1) Cationic modification

[0042] Modification liquid formula: the dosage of Glytac A is 6% (o.w.f.), the dosage of Pingpingjia O is 1% (o.w.f.), and the bath ratio is 1:20.

[0043] Modification process: at room temperature, put cotton fabric in the modified liquid, raise the temperature to 85°C at a rate of 1-2°C / min, and keep it warm for 20 minutes; then cool down the mixture system of cotton fabric and modified liquid to 35°C ℃, wherein caustic soda is added to make the concentration of caustic soda in the solution reach 0.5g / L, react for 20 minutes, take out and wash with water.

[0044](2) reactive dye dyeing and soaping: with embodiment one.

Embodiment 3

[0046] The present embodiment selects pure cotton knitted fabric to carry out dyeing treatment, and concrete steps are as follows:

[0047] (1) Cationic modification

[0048] Modification solution formula: cationic modifier YJZ-50 dosage 5% (o.w.f.), Pingpinga O dosage 0.8% (o.w.f.), liquor ratio 1:25.

[0049] Modification process: at room temperature, put cotton fabric in the modified liquid, raise the temperature to 90°C at a rate of 1-2°C / min, and keep it warm for 20 minutes; then cool down the mixture system of cotton fabric and modified liquid to 34 ℃, wherein caustic soda is added to make the concentration of caustic soda in the solution reach 1g / L, react for 20 minutes, take out and wash with water.

[0050] (2) reactive dye dyeing and soaping: with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com