Method for preparing bio- diesel oil

A technology of biodiesel and bio-oil, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems of low activity of heterogeneous catalysts, need repeated regeneration, and slow reaction speed, and achieve easy separation and reaction. The effect of fast speed and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

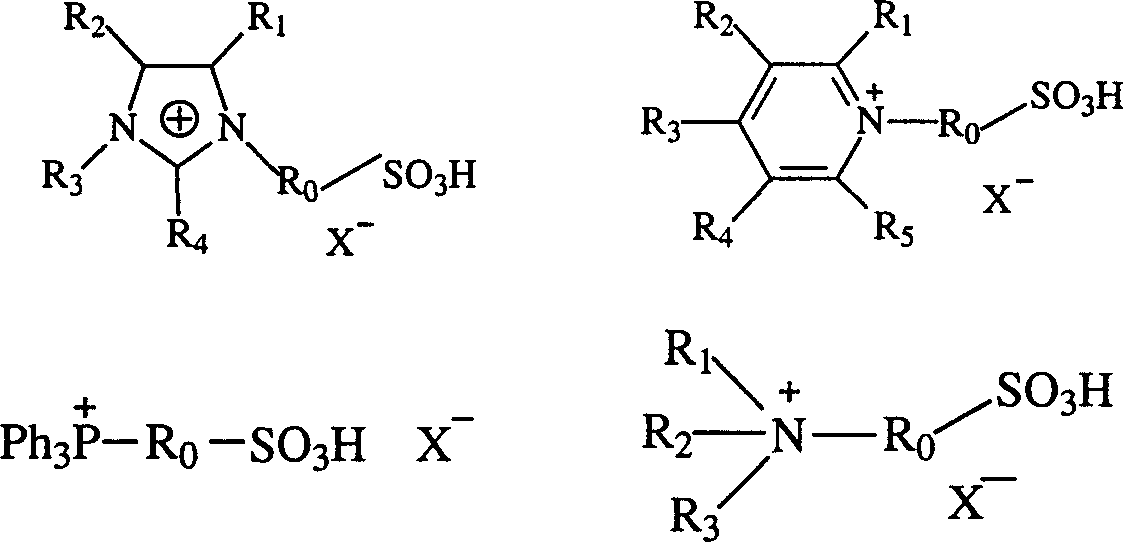

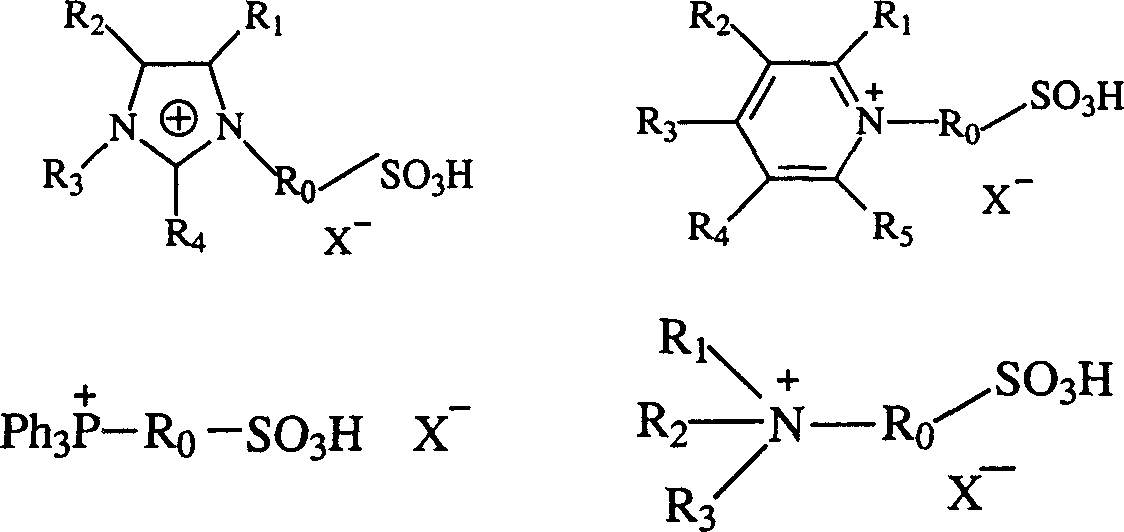

Method used

Image

Examples

Embodiment 1

[0025] At reaction temperature 20 ℃, under the condition of pressure 0.1MPa, castor oil, methanol mixed solution (molar ratio 1: 30) that will mix homogeneously joins in the methylimidazolium bisulfate ionic liquid catalyst (castor oil and ionic liquid Molar ratio 1: 1), stirring, stop stirring after 10 hours of reaction, leave the reaction solution to stand and separate layers, take out the product in the upper layer, and recycle the catalyst in the lower layer.

Embodiment 2

[0027] At reaction temperature 300 DEG C, under pressure 2MPa condition, the rapeseed oil that mixes uniformly, ethanol mixed solution (molar ratio 1: 10) joins in trifluoromethanesulfonate butylsulfonate pyridinium ionic liquid catalyst (rapeseed oil and Ionic liquid molar ratio 1:1), stirring, stop stirring after reacting for 0.1 hour, leave the reaction solution to stand and separate layers, take out the product in the upper layer, and recycle the catalyst in the lower layer.

Embodiment 3

[0029] At reaction temperature 150 DEG C, under pressure 1MPa condition, the soybean oil that mixes uniformly, propanol mixed solution (molar ratio 1: 1) is joined in p-toluenesulfonic acid hexylsulfonate triphenylphosphine ionic liquid catalyst (soybean oil and The ionic liquid molar ratio is 300:1), stirring, and the stirring is stopped after 5 hours of reaction, and the reaction solution is allowed to stand for stratification, and the product in the upper layer is taken out, and the catalyst in the lower layer is recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com