Preparation method of load-type metallic oxide ozone catalytic oxidation catalyst

A technology of ozone catalytic oxidation and oxidation, which is applied in the preparation of supported catalysts and the preparation of supported metal oxide ozone catalytic oxidation catalysts, can solve the problems of increased processing costs, low reaction rate, and difficult recovery, and achieve production Low preparation cost, simple preparation process, good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

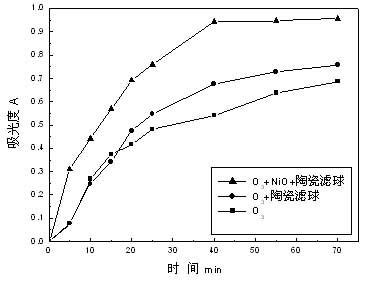

Embodiment 1

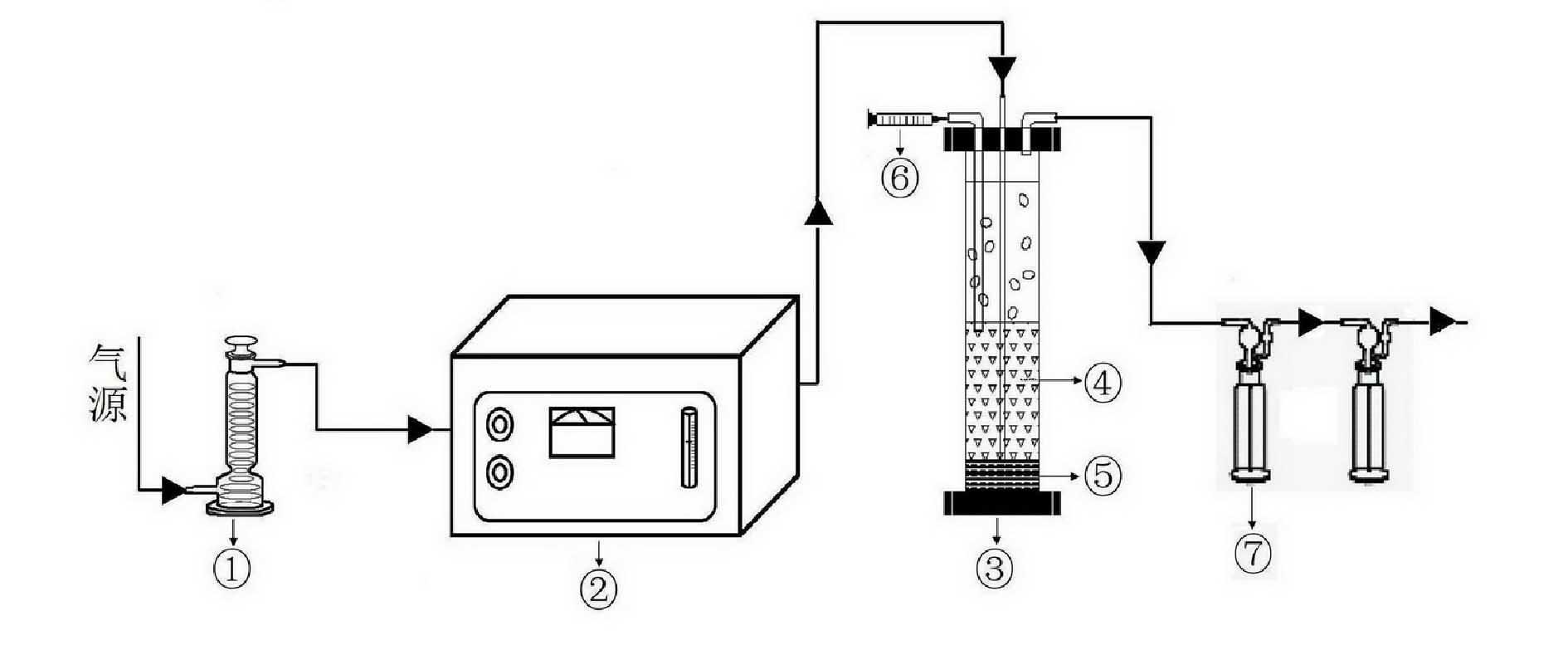

[0029] A preparation method of supported metal oxide ozone catalytic oxidation catalyst, it comprises the steps:

[0030] (1) Carrier pretreatment: select ordinary ceramic filter balls with a particle size of about 3.0 mm as the carrier, wash them with deionized water for 2 to 5 times, and soak the washed ceramic filter balls in 0.1mol / L dilute hydrochloric acid for 24 hours , and then washed with deionized water until the effluent is neutral, then dried to obtain pretreated ceramic filter balls;

[0031] (2) The pretreated ceramic filter ball is 0.5mol / L nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) soaking in the solution, drying the obtained soaking material after soaking for 24 hours, and obtaining ceramic filter balls after soaking and drying;

[0032] (3) Roast the impregnated and dried ceramic filter balls in a muffle furnace at 500°C (heating rate: 10°C / min) for 5 hours to obtain a roasted product;

[0033] (4) The calcined product is washed with deionized water for 2 to 5 ...

Embodiment 2

[0036] A preparation method of supported metal oxide ozone catalytic oxidation catalyst, it comprises the steps:

[0037] (1) Pretreatment of the carrier: select a ceramic filter ball with a particle size of about 3.0 mm as the carrier, wash it with deionized water for 2 to 5 times, soak the washed ceramic filter ball in 0.1mol / L dilute hydrochloric acid for 24 hours, Then wash with deionized water until the effluent is neutral, then dry to obtain pretreated ceramic filter balls;

[0038] (2) The pretreated ceramic filter ball is 0.1mol / L nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) soaking in the solution, drying the obtained soaking material after soaking for 24 hours, and obtaining ceramic filter balls after soaking and drying;

[0039] (3) Roast the impregnated and dried ceramic filter balls in a muffle furnace at 500°C (heating rate: 10°C / min) for 5 hours to obtain a roasted product;

[0040] (4) The calcined product is washed with deionized water for 2 to 5 times and then dr...

Embodiment 3

[0043] A preparation method of supported metal oxide ozone catalytic oxidation catalyst, it comprises the steps:

[0044] (1) Pretreatment of the carrier: select a ceramic filter ball with a particle size of about 3.0 mm as the carrier, wash it with deionized water for 2 to 5 times, soak the washed ceramic filter ball in 0.1mol / L dilute hydrochloric acid for 24 hours, Then wash with deionized water until the effluent is neutral, then dry to obtain pretreated ceramic filter balls;

[0045] (2) The pretreated ceramic filter ball is 0.3mol / L nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) soaking in the solution, drying the obtained soaking material after soaking for 24 hours, and obtaining ceramic filter balls after soaking and drying;

[0046] (3) Roast the impregnated and dried ceramic filter balls in a muffle furnace at 500°C (heating rate: 10°C / min) for 5 hours to obtain a roasted product;

[0047] (4) The calcined product is washed with deionized water for 2 to 5 times and then drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com