Preparation method for SiO2 sol with high evenness degree

A technology of silica and silica sol, applied in the directions of silica and silica, can solve the problems of difficult to obtain silica sol with particle size distribution, application limitation of silica sol, etc., to improve the reaction rate, eliminate local concentration unevenness, high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) In a 1000ml three-necked bottle, add 200ml of water, add 20g of metal silicon powder with 300 mesh purity of 98% and 4g of sodium hydroxide, adjust the reaction temperature to 60°C, stir at 200rpm, and react under 50KHZ ultrasonic conditions 2 hours, 15 minutes of ultrasound every 1 hour to prepare silica sol seed liquid;

[0036] (2) In the above-mentioned prepared seed liquid, the reaction temperature was adjusted to 80°C, the stirring rate was 250rpm, and the reaction was carried out under 50KHZ ultrasonic conditions for 2 hours, and 100g of 1wt% sodium hydroxide solution was added for every 1 hour of ultrasonication for 20 minutes. 8g of metal silicon powder with 300 mesh purity of 98%;

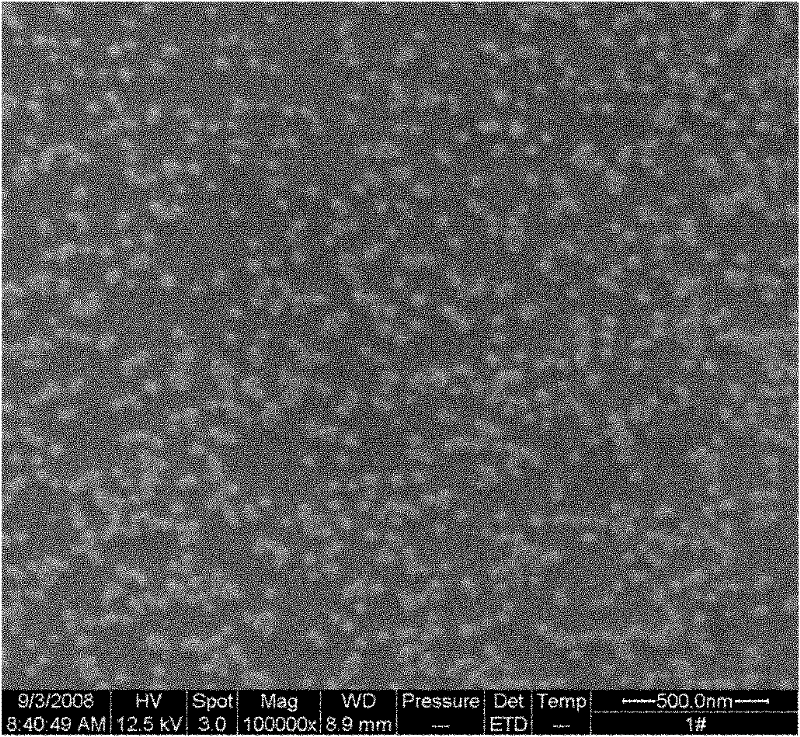

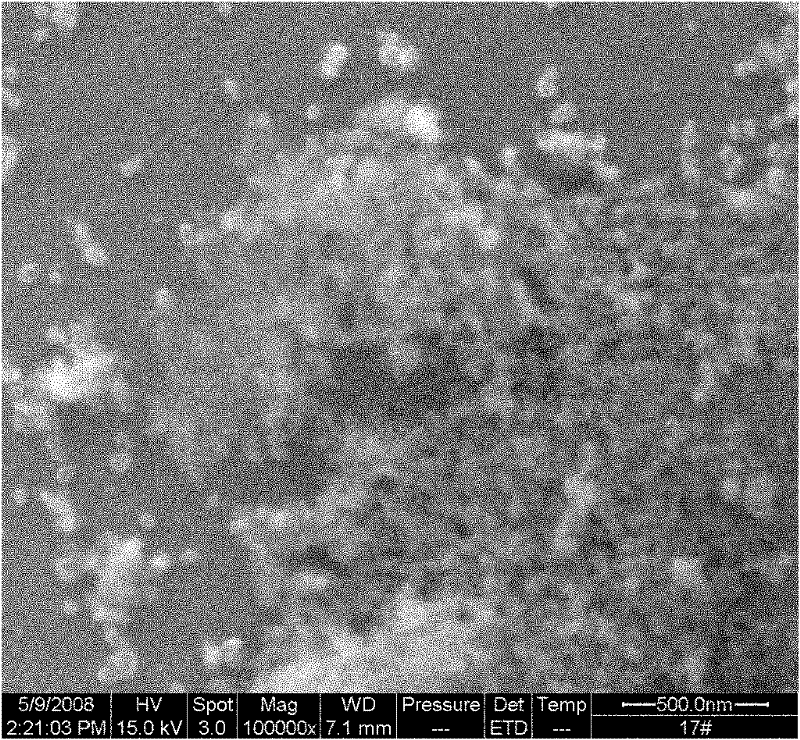

[0037] (3) Repeat step (2) twice again, after cooling, get 600g concentration after filtration and be the silica sol of 15wt% uniform particle size distribution, use SEM test particle size to be 35nm, test result is as follows figure 1 , figure 2 It is the SEM picture of the...

Embodiment 2

[0039] (1) In a 1000ml three-necked bottle, add 200ml of water, add 16g of metal silicon powder with 300 mesh purity of 98% and 2g of sodium hydroxide, adjust the reaction temperature to 70°C, stir at 200rpm, and react under 50KHZ ultrasonic conditions 4 hours, 20 minutes of ultrasound every 1 hour to prepare silica sol seed liquid;

[0040] (2) In the seed liquid prepared above, adjust the reaction temperature to 85°C, the stirring rate is 400rpm, and react under 50KHZ ultrasonic conditions for 2 hours, ultrasonic for 15 minutes every hour, and add 120g of 0.8wt% sodium hydroxide solution And 300 mesh purity is 8g of metal silicon powder of 98%;

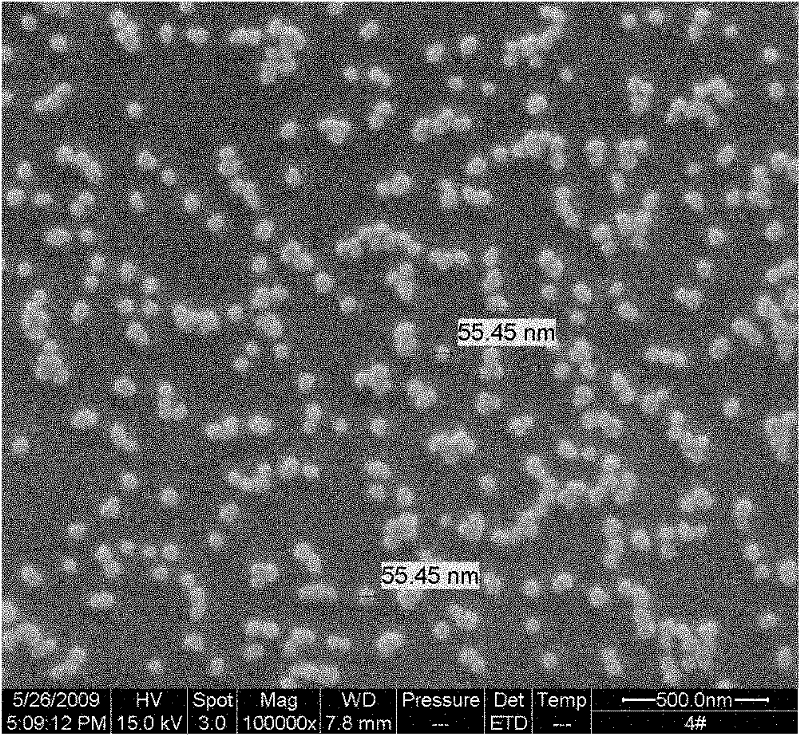

[0041] (3) repeat step (2) three times again, after cooling, get 600g concentration after filtering and be the silica sol of 16wt% uniform particle size distribution, use SEM test particle size to be 55nm, test result is as follows image 3 .

Embodiment 3

[0043] (1) In a 1000ml three-necked bottle, add 200ml of water, add 17g of 300-mesh metal silicon powder with a purity of 98% and 3g of sodium hydroxide, adjust the reaction temperature to 80°C, stir at 200rpm, and react under 50KHZ ultrasonic conditions 4 hours, 20 minutes of ultrasound every 1 hour to prepare silica sol seed liquid;

[0044] (2) In the seed liquid prepared above, adjust the reaction temperature to 90°C, the stirring rate is 400rpm, and react under 70KHZ ultrasonic conditions for 2 hours, ultrasonic for 15 minutes every hour, and add 120g of 0.6wt% sodium hydroxide solution and 300 meshes of 98% metallic silicon powder 6g;

[0045] (3) repeat step (2) four times again, after cooling, get 800g concentration after filtering and be the silica sol of 12wt% uniform particle size distribution, use SEM test particle size to be 65nm, test result is as follows Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com