Preparation method of composite protein foaming agent

A technology of compounding protein and foaming agent, applied in protein food processing, animal protein processing, vegetable protein processing and other directions, can solve the problems of reducing foaming, long technical cycle, unsatisfactory and other problems, achieve good foaming ability, improve The effect of adaptability, good foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

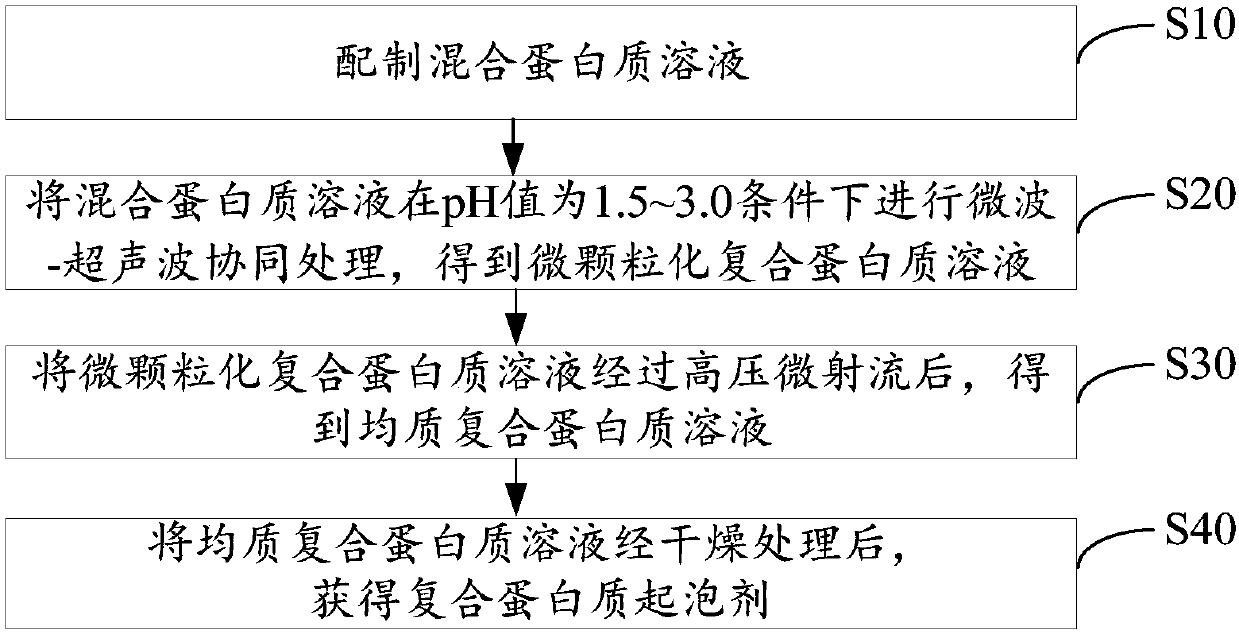

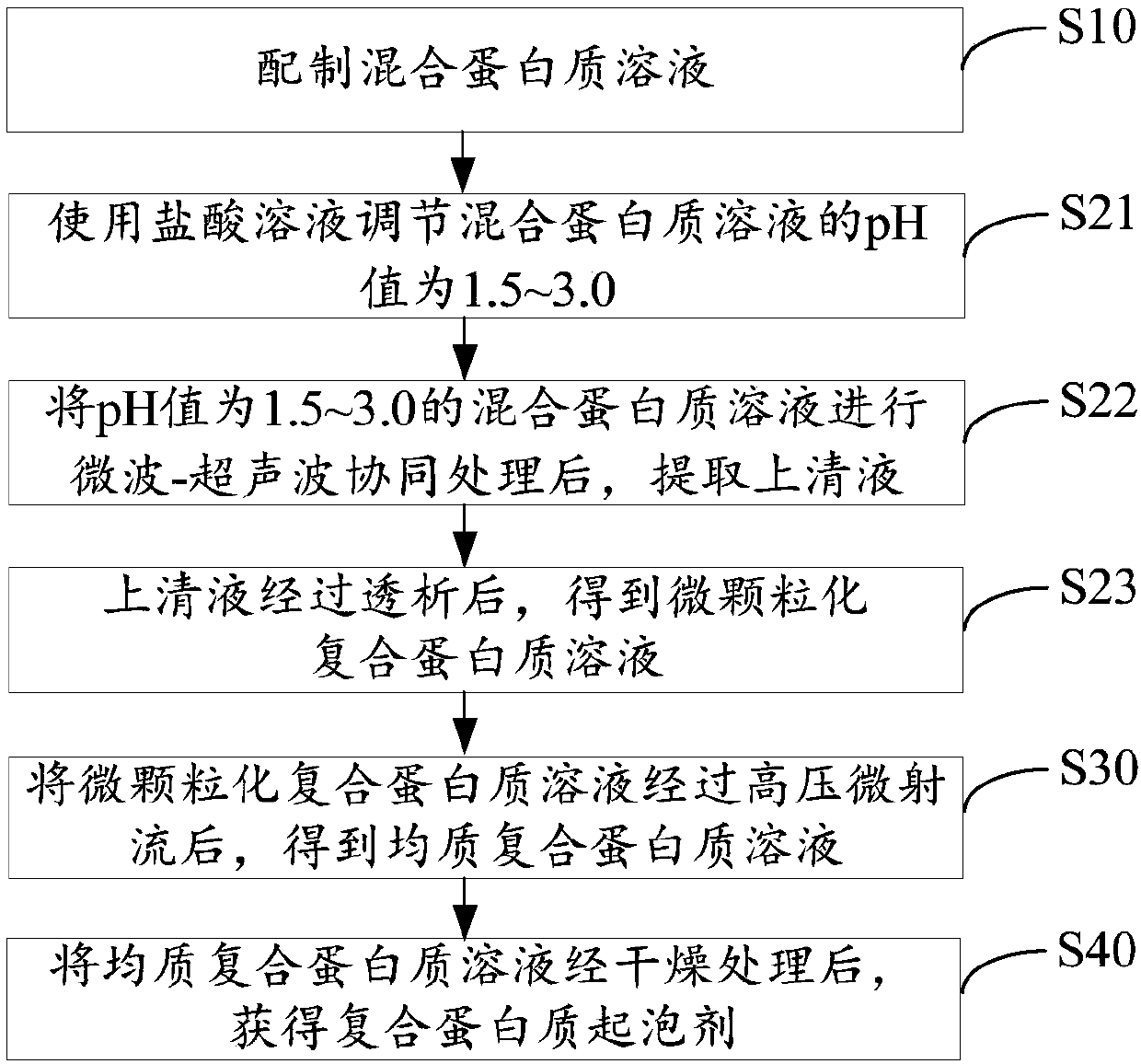

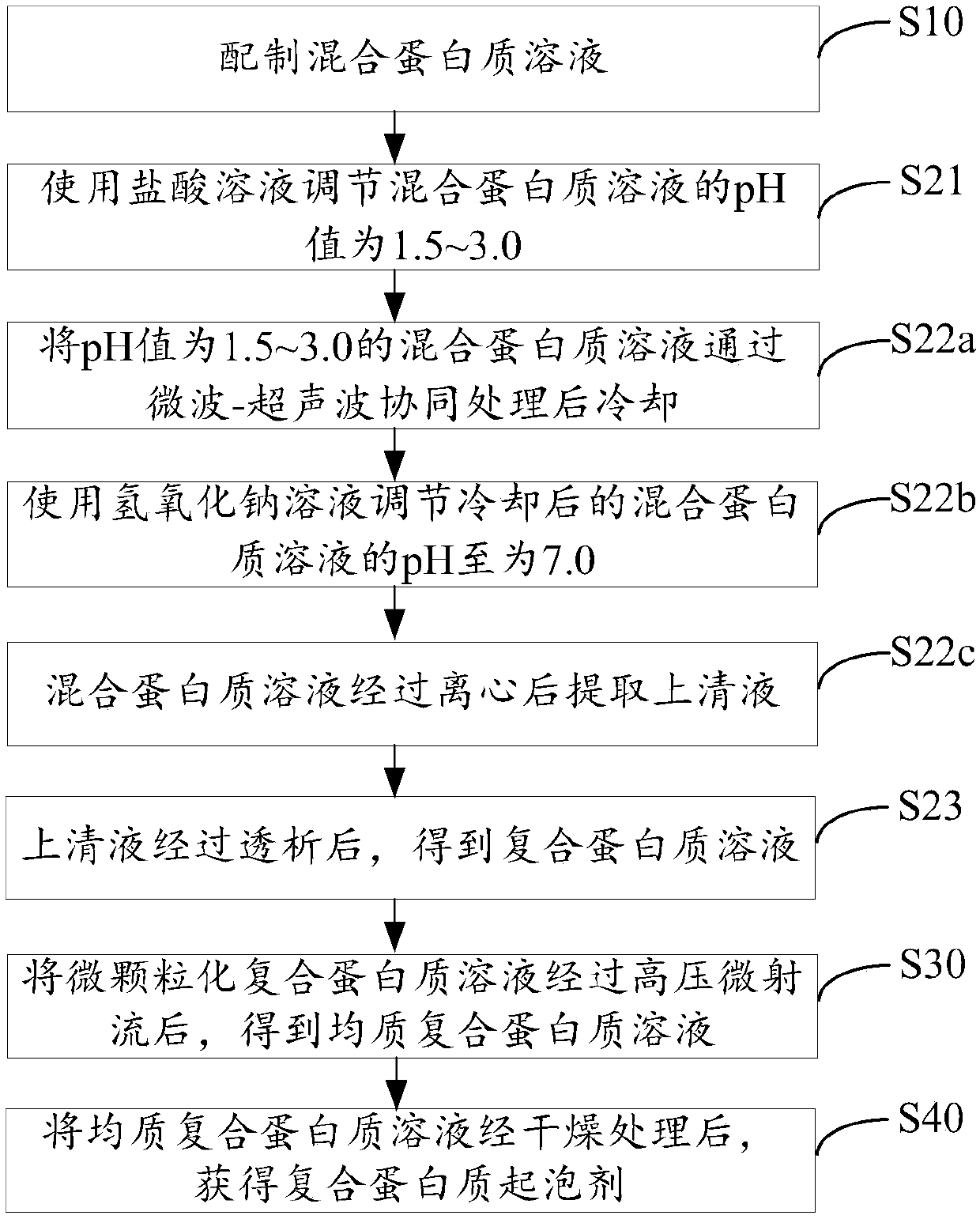

[0033] The invention proposes a preparation method of a composite protein foaming agent, figure 1 For an embodiment of the preparation method of the composite protein foaming agent provided by the present invention, please refer to figure 1 , the preparation method of described composite protein foaming agent comprises the steps:

[0034] Step S10, preparing a mixed protein solution;

[0035] Wherein, the mixed protein solution includes at least two of soybean protein, rice protein, rapeseed protein, rice bran protein, whey protein, casein and ovalbumin.

[0036] Dissolve at least two of the above-mentioned proteins in deionized water respectively, stir well and leave overnight to fully hydrate the protein, prepare a protein solution with a certain concentration, and then mix the two evenly to obtain the mixed protein solution . In practice, some proteins have excellent foaming ability but poor foam stability, while some proteins have the opposite foaming properties. By com...

Embodiment 1

[0064] (1) Preparation of mixed protein solution: Weigh rice bran protein and ovalbumin and dissolve them in deionized water respectively to prepare a protein solution with a concentration of 10 mg / mL, stir for 10 minutes and place it overnight; then put rice bran protein in a four-way round bottom flask The solution and the ovalbumin solution were mixed at a ratio of 1:1, and stirred for 5 minutes to obtain a mixed protein solution; then the pH value of the mixed protein solution was adjusted to 1.5 using 1 mol / mL hydrochloric acid solution.

[0065] (2) Prepare the composite protein solution: put the mixed protein solution into the microwave-ultrasonic synergistic synthesis reactor, adjust the microwave power to 300W, the ultrasonic power to 100W, control the temperature of the reaction system to 90°C, the reaction time to 5min, and the reaction ends Finally, the composite protein solution was prepared and cooled to room temperature; then the pH value of the composite protein...

Embodiment 2

[0068] (1) Preparation of mixed protein solution: Weigh rice bran protein and ovalbumin and dissolve them in deionized water respectively to prepare a protein solution with a concentration of 20 mg / mL, stir for 10 minutes and place overnight; then put rice bran protein in a four-way round bottom flask The solution and the ovalbumin solution were mixed at a ratio of 2:1, and stirred for 5 minutes to obtain a mixed protein solution; then the pH value of the mixed protein solution was adjusted to 1.5 using 1 mol / mL hydrochloric acid solution.

[0069] (2) Preparation of complex protein solution: put the mixed protein solution into a microwave-ultrasonic synergistic reaction apparatus, adjust the microwave power to 500W, the ultrasonic power to 300W, control the temperature of the reaction system to 90°C, and the reaction time to 5min, the reaction ends Finally, the composite protein solution was prepared and cooled to room temperature; then the pH value of the composite protein so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com