Sustained-release foaming agent

A foaming agent and slow technology, applied in the field of gas field foam drainage agent and solid slow-release foaming agent, it can solve the problems of gas permeability damage, gas well production decline, drowning and other problems, and achieve high salinity resistance. , The effect of strong foaming ability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The slow-release foaming agent in this example consists of the following components: 20% Sapinberry extract, fatty alcohol polyoxyethylene ether AEO 18 13.3%, polylauroyldiethanolamine 6.7%, polyvinyl alcohol PVA 10%, acrylic resin 50%, that is, the compounding ratio of foaming agent component, polyvinyl alcohol PVA, and acrylic resin is 4:1:5.

Embodiment 2

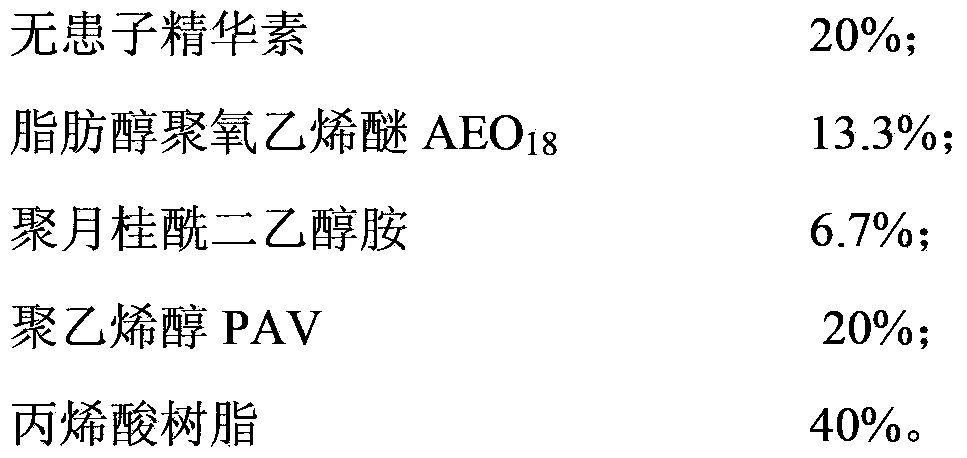

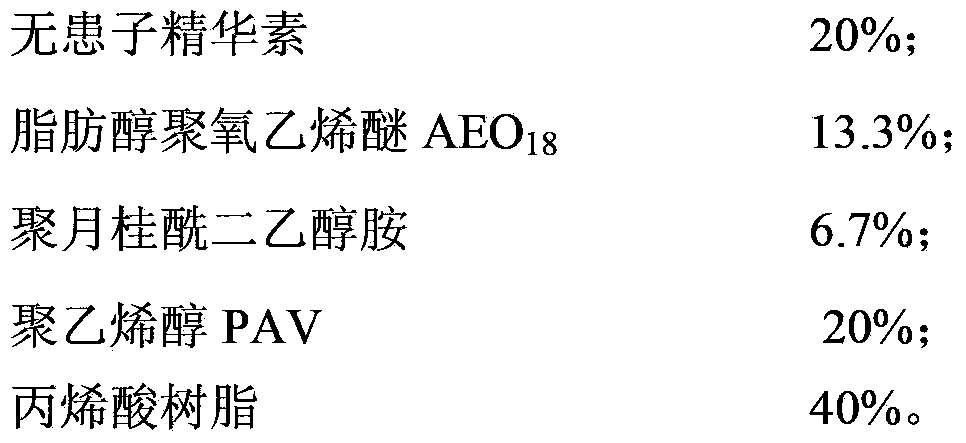

[0022] The slow-release foaming agent in this example consists of the following components: 20% Sapinberry extract, fatty alcohol polyoxyethylene ether AEO 18 13.3%, polylauroyldiethanolamine 6.7%, polyvinyl alcohol PVA 20%, acrylic resin 40%, that is, the compounding ratio of foaming agent component, polyvinyl alcohol PVA, and acrylic resin is 4:2:4.

Embodiment 3

[0024] The slow-release foaming agent in this example consists of the following components: 20% Sapinberry extract, fatty alcohol polyoxyethylene ether AEO 18 13.3%, polylauroyldiethanolamine 6.7%, polyvinyl alcohol PVA 30%, acrylic resin 30%, that is, the compounding ratio of foaming agent component, polyvinyl alcohol PVA, and acrylic resin is 4:3:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com