Thin-wall part machining method

A processing method and technology for thin-walled parts, applied in the field of aero-engine manufacturing, can solve the problems of tool or measuring tool interference, disc-type parts end face and measuring tool interference, increasing the difficulty of measuring tool design, etc., to achieve the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

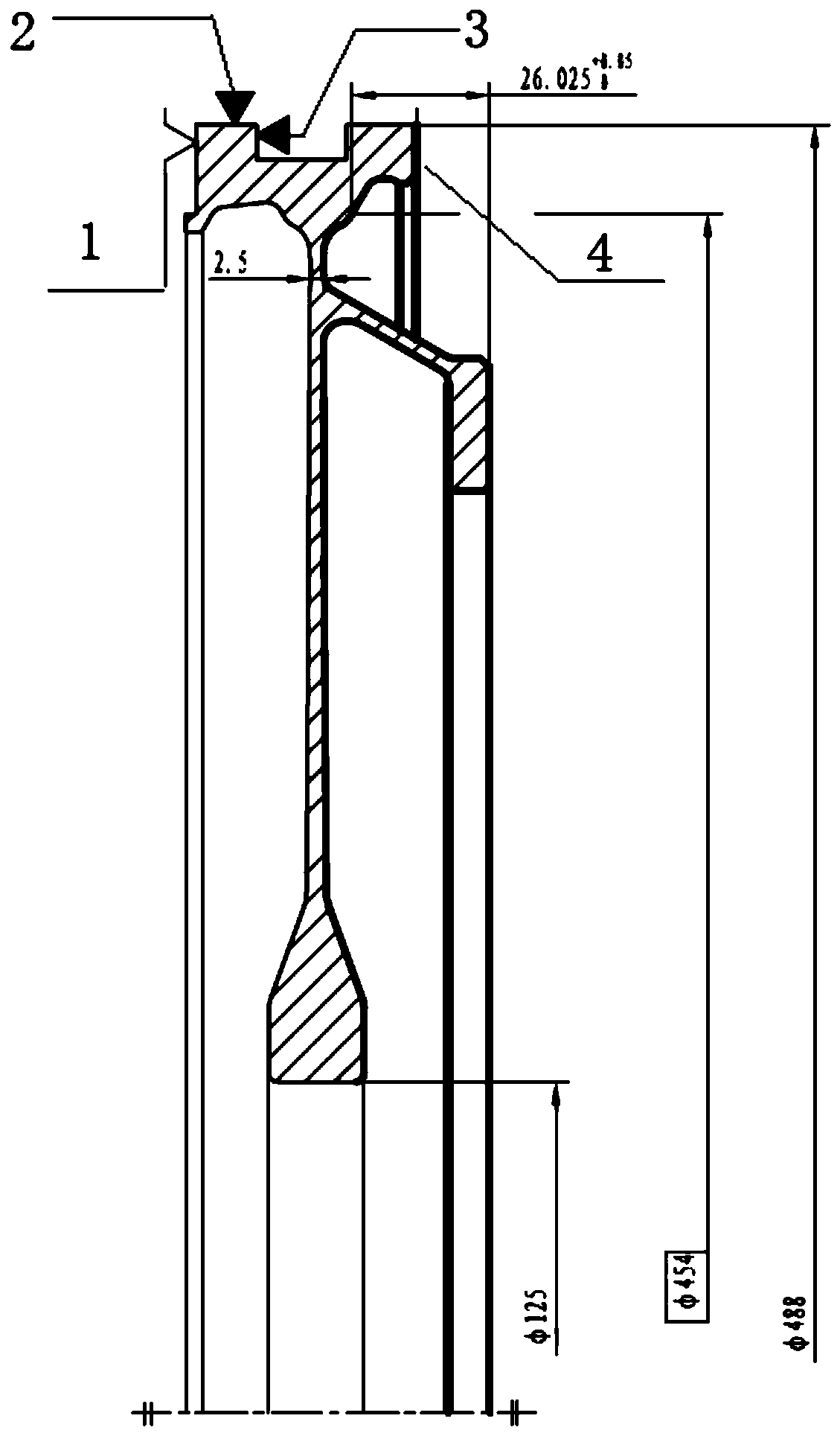

[0021] Such as figure 1 As shown, it is a high-pressure compressor disk part. The compressor disk is a large-span thin-walled disk part. Due to the large structural size of the part, the outer circle size of the part is The size of the inner hole is The thinnest part wall thickness is only 2.5mm. This part belongs to the thin-walled compressor disk part, and it must be clamped by supporting positioning and pressing during processing. Considering the cost factor in the processing, the concave-shaped construction edge is used to ensure that all the turning processing can be completed with one fixture.

[0022] The specific processing method is: reserve 5mm of the radial length of the outer circle at the largest part of the outer circle as the annular machining allowance sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com