Processing method of sugar-free pickled green plum fruit products

A processing method and technology of greengage, applied in the confectionary industry, confectionery, food ingredients, etc., can solve the problems of yellowish color, bitter taste, etc., and achieve the effects of improving taste, delaying degradation, and increasing hardness and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

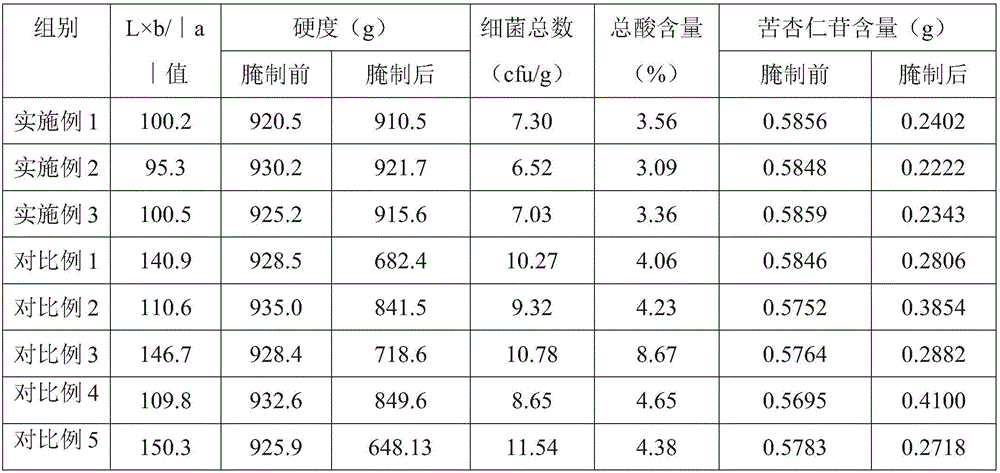

Examples

Embodiment 1

[0030] Embodiment 1, a kind of processing method of sugar-free green plum pickled fruit

[0031] The processing method of sugar-free green plum pickled fruit described in embodiment 1 of the present invention comprises the following steps:

[0032] A) Cleaning: select 6 mature turquoise plums that are complete and non-rotten, clean them, remove them, drain them, and dry them for later use;

[0033] B) Blanching: put the green plums into the blanching solution, blanching at 105°C for 1 min, then remove; wash twice, dry in the air, and set aside;

[0034] C) Debittering: Put the above-mentioned greengage treated by step B) in an ethanol solution with a concentration of 75% (V / V) and soak for 5 minutes, then add a bitterness inhibitor, ultrasonically treat at 45°C for 30 minutes, take it out and shake it to drain Go to ethanol solution;

[0035] D) Sugar alcohol pickling: place the greengage processed by step C) in 5wt% sugar alcohol solution, seal and marinate for 24h; adjust ...

Embodiment 2

[0039] Embodiment 2, a kind of processing method of sugar-free green plum pickled fruit

[0040] The processing method of sugar-free green plum pickled fruit described in the embodiment of the present invention 2 comprises the following steps:

[0041] A) Cleaning: select 6 mature turquoise plums that are complete and non-rotten, clean them, remove them, drain them, and dry them for later use;

[0042] B) Blanching: put the green plums into the blanching solution, blanching at 103°C for 2 minutes, then remove; wash twice, dry in the air, and set aside;

[0043] C) Debittering: Put the above-mentioned greengage treated by step B) in an ethanol solution with a concentration of 75% (V / V) and soak for 5 minutes, then add a bitterness inhibitor, ultrasonically treat at 40°C for 35 minutes, take it out and shake it to drain Go to ethanol solution;

[0044] D) Sugar alcohol pickling: place the greengage processed by step C) in 5wt% sugar alcohol solution, seal and marinate for 24h;...

Embodiment 3

[0048] Embodiment 3, a kind of processing method of sugar-free green plum pickled fruit

[0049] Example 2 is repeated in the same steps, but the blanching liquid in the step B) is composed of citric acid, sodium bicarbonate and calcium chloride in a weight ratio of 1:0.5:1; the bitterness is suppressed in the step C). The agent is composed of β-cyclodextrin and riboflavin binding protein in a weight ratio of 1:1; the sugar alcohol solution in the step D) is composed of xylooligosaccharide and inulin in a weight ratio of 1:0.6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com