Processing method of crank connecting rod

A processing method and technology of crank connecting rod, applied in the field of machinery, can solve the problems such as the impact toughness of connecting rod, easy fracture of crank connecting rod, short service life, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

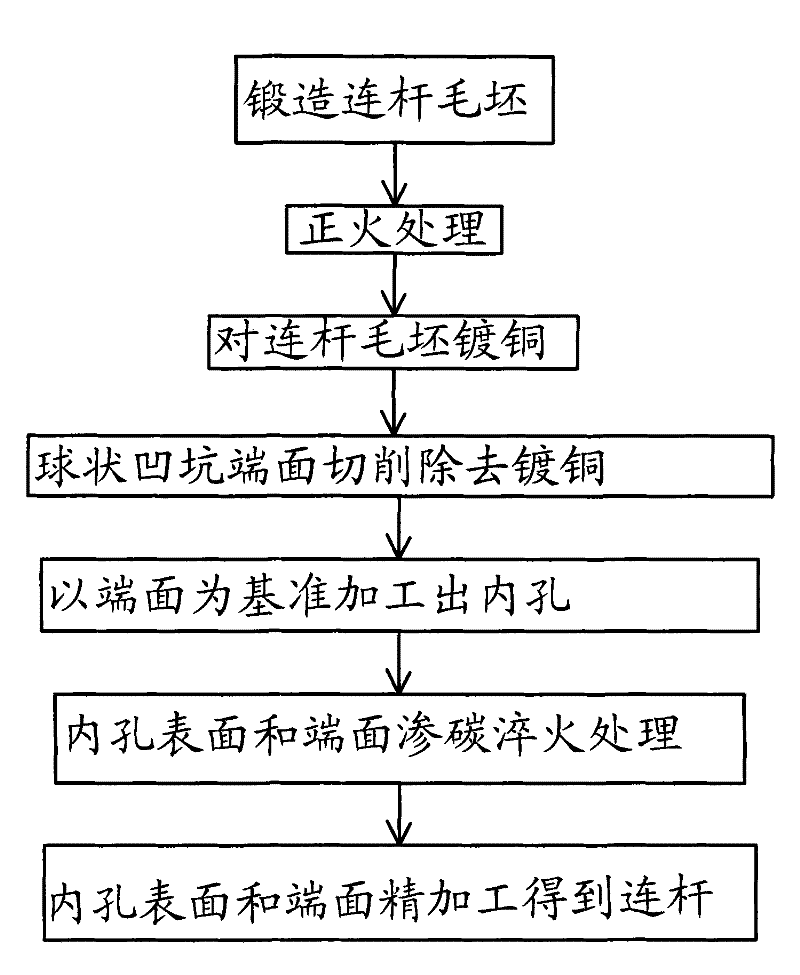

[0035] Such as figure 1 As shown, the processing method of the crank connecting rod comprises the following steps:

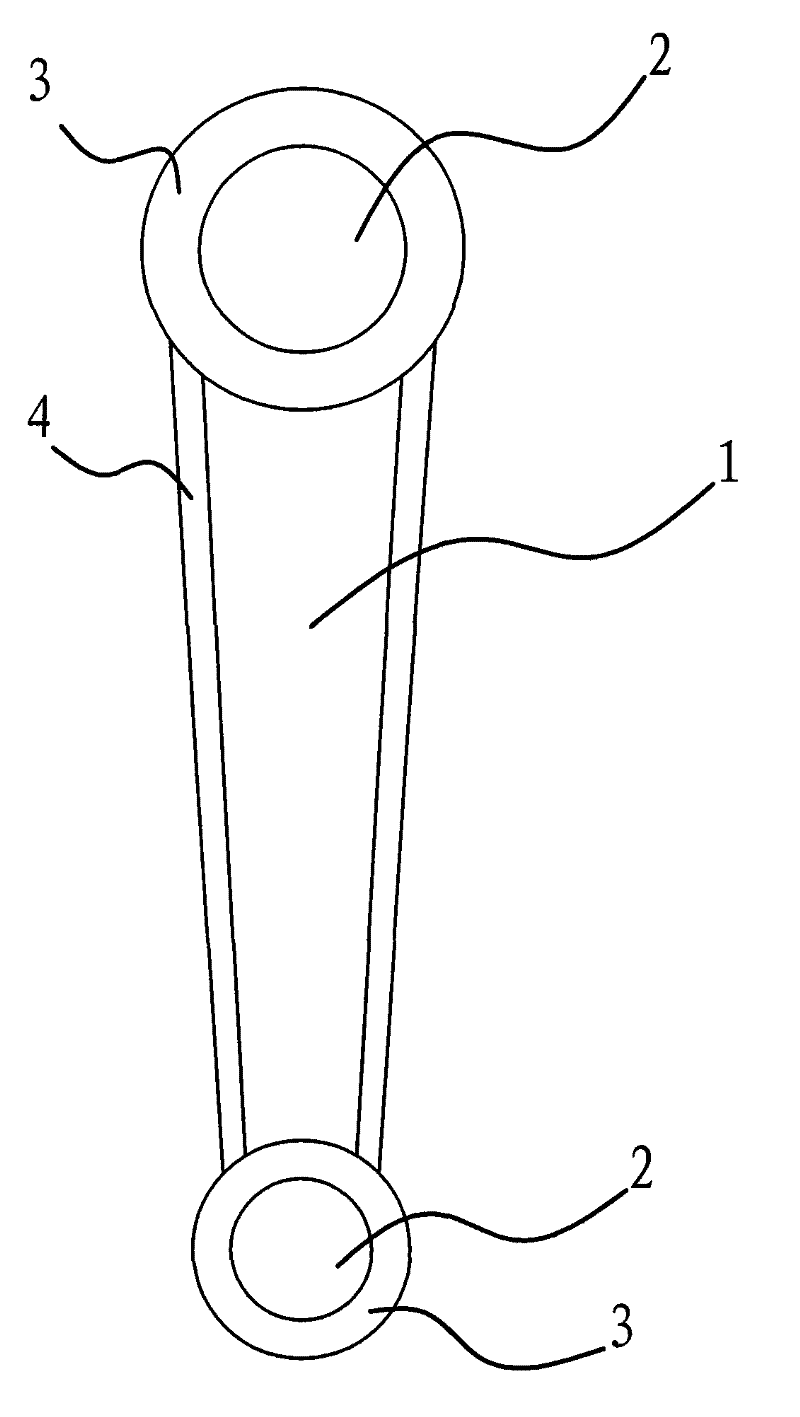

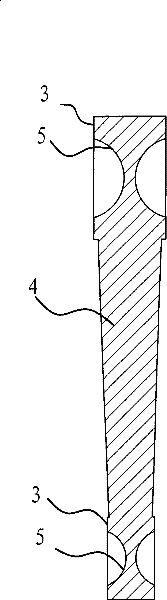

[0036] Select low-carbon alloy steel to forge a connecting rod blank 1, the connecting rod blank 1 is strip-shaped, and one end of the connecting rod blank 1 is large, the other end is small, and the ends of the big end and the small end each have a pair of opposite hemispheres Shaped pit 5. The plane at the hemispherical pit 5 is the end face 3, which is the end face 3 of the inner hole 2, and the middle part of the connecting rod blank 1 is the rib plate 4, such as figure 2 and image 3 shown. The low carbon alloy steel in this example is 20CrMo alloy steel. 20CrMn alloy steel, 20CrMnSi alloy steel, 20CrMoTi alloy steel or 25CrMo alloy steel can also be selected.

[0037] The connecting rod blank 1 is subjected to normalizing treatment at a temperature of 900°C; at this temperature, the hardness of the connecting rod blank 1 can reach HB175. After norm...

Embodiment 2

[0041] The content of Example 2 is basically the same as that of Example 1, except that the connecting rod blank 1 is subjected to normalizing treatment at a temperature of 890°C; at this temperature, the hardness of the connecting rod blank 1 can reach HB170. The thickness of the copper plating obtained after electroplating at normal temperature is 0.03mm. Carburizing is carried out in a heat treatment mesh belt furnace, heated to 850°C, the depth of the carburized layer is 0.7mm, and the hardness reaches HRC60.

Embodiment 3

[0043] The content of Example 3 is basically the same as that of Example 1, except that the connecting rod blank 1 is subjected to normalizing treatment at a temperature of 910°C; at this temperature, the hardness of the connecting rod blank 1 can reach HB185. The thickness of the copper plating obtained after electroplating at normal temperature is 0.05 mm. Carburizing is carried out in a heat treatment mesh belt furnace, heated to 870°C, the depth of the carburized layer is 1.0mm, and the hardness reaches HRC64.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com