A near-infrared photoelectric device and a processing method thereof

A near-infrared light and processing method technology, applied in optical components, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of weak photoelectric response ability, slow device response speed, etc., to achieve short response time, uniform gap size, The effect of improving optical and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

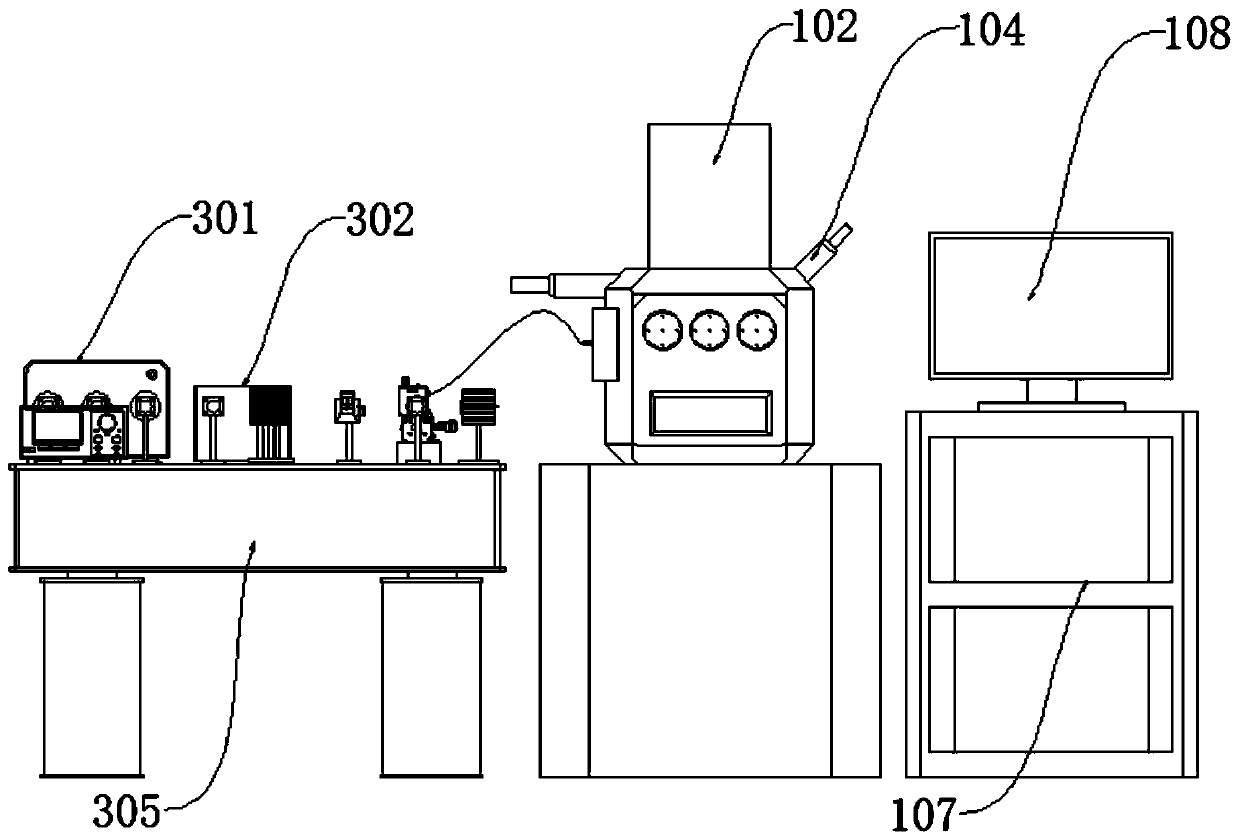

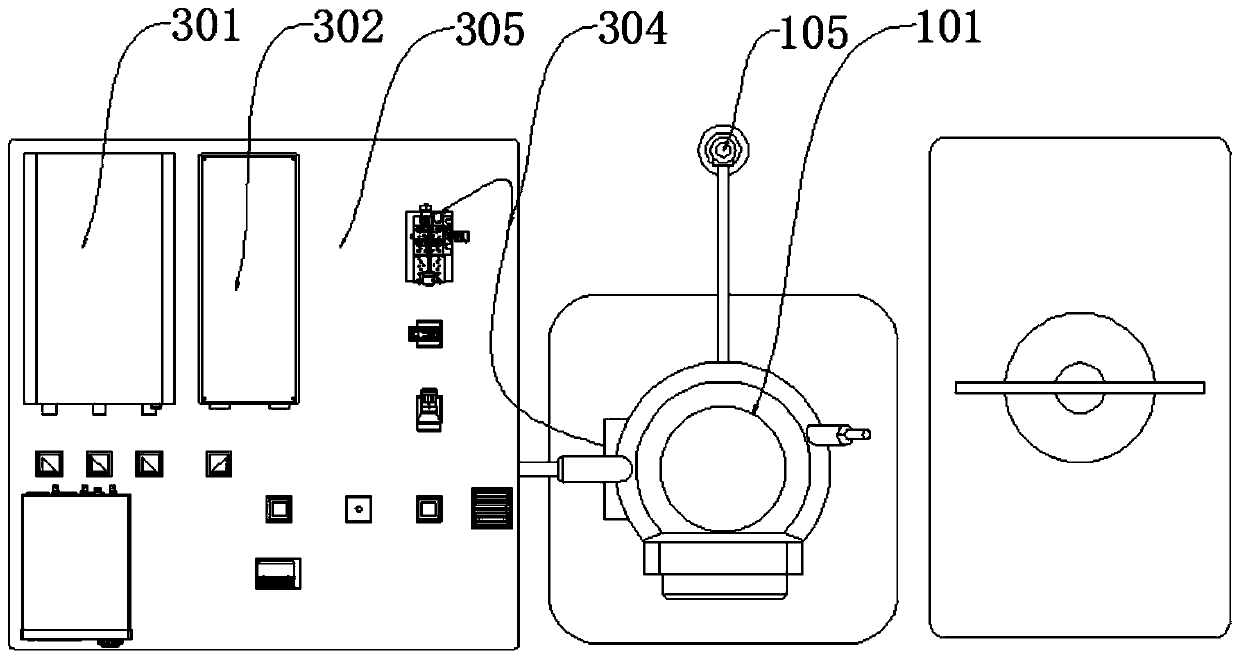

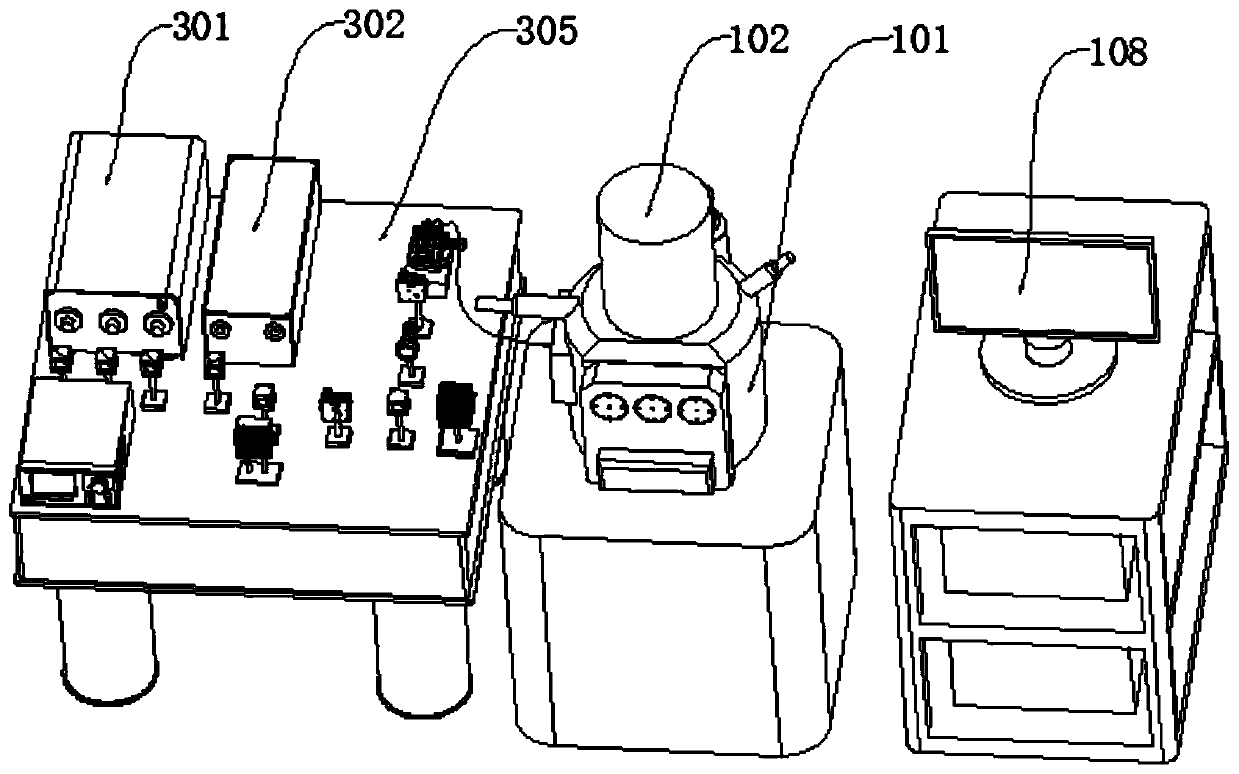

[0070] A nano-junction device, such as Figure 1 to Figure 3 As shown, it includes a vacuum cavity 101, a near-field light generating device, a nano-manipulation device and a control device 107, the near-field light generating device includes a vacuum cavity laser emitting device and an execution end, and the nano-manipulation device includes a sample stage and an execution end Operating device; the nano-manipulating device is arranged inside the vacuum chamber 101, the execution end is connected to the execution-end operating device, the near-field light generating device and the nano-manipulating device are respectively connected to the control device 107 connected; the sample stage is suitable for moving the sample, and the execution end operation device is suitable for driving the execution end to move.

[0071] Here, the sample is a silicon wafer with nanoparticles and nanowires dispersed on its surface. In actual operation, the sample stage is provided with a sample plac...

Embodiment 2

[0074] Like the embodiment described above, this embodiment differs from it in that, as Figure 1 to Figure 4 As shown, the near-field light generating device includes: a laser emitting device, a fiber coupler 303 and an execution end, the laser emitting device is suitable for generating a laser beam, and the fiber coupler 303 is connected to the execution end through an optical fiber 304, so The fiber coupler 303 is suitable for coupling the laser beam into the optical fiber 304; the execution end is suitable for generating near-field light by using the laser beam.

[0075] The advantage of this arrangement is that the spatially free laser beam is coupled into the optical fiber 304 through the optical fiber coupler 303 , and then the optical fiber 304 is used to connect to the execution end, and the laser beam is delivered to the execution end through the optical fiber 304 .

[0076] Such as Figure 1 to Figure 4 As shown, the laser emitting device and the fiber coupler 303 ...

Embodiment 3

[0080] Like the embodiment described above, this embodiment differs from it in that, as Figure 1 to Figure 4 As shown, the laser emitting device includes a laser 301 and a laser parameter amplifier 302, the laser 301 is suitable for emitting the laser beam, the laser beam is emitted through the laser 301, and then enters the laser parameter amplifier 302, so The laser parameter amplifier 302 is suitable for adjusting the wavelength of the laser beam. The advantage of such setting is that the wavelength of the laser beam can be controlled through the setting of the laser parameter amplifier 302 .

[0081] Optionally, as in image 3 and Figure 4 As shown, the laser emitting device also includes a reflector 313, the mirror surface 315 of the reflector 313 presents a set angle with the laser beam emitted by the laser 301, and the reflector 301 is suitable for the The laser beam emitted by the laser 301 is reflected to the laser parameter amplifier 302 . The advantage of this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com