High-length-to-diameter ratio variable-section slender shaft ultrasonic elliptical vibration turning machining method

A technology with elliptical vibration and large aspect ratio, which is used in turning equipment, turning equipment, metal processing equipment, etc. to improve processing efficiency, reduce processing costs, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

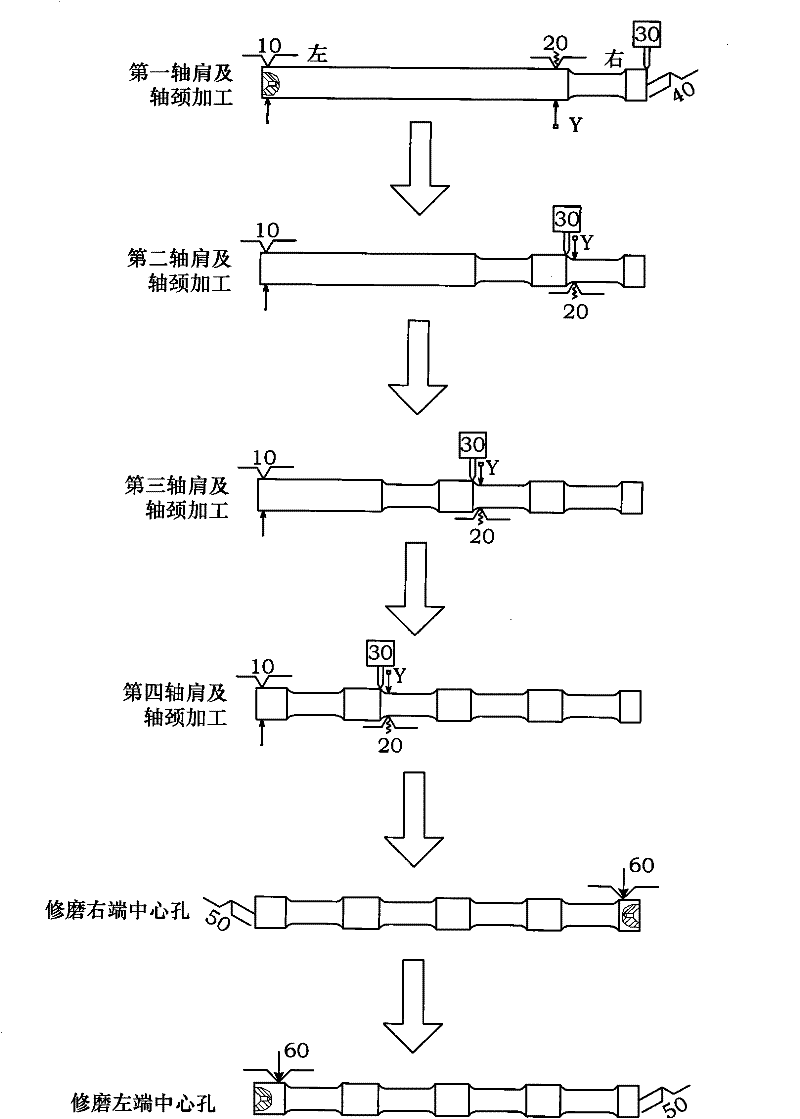

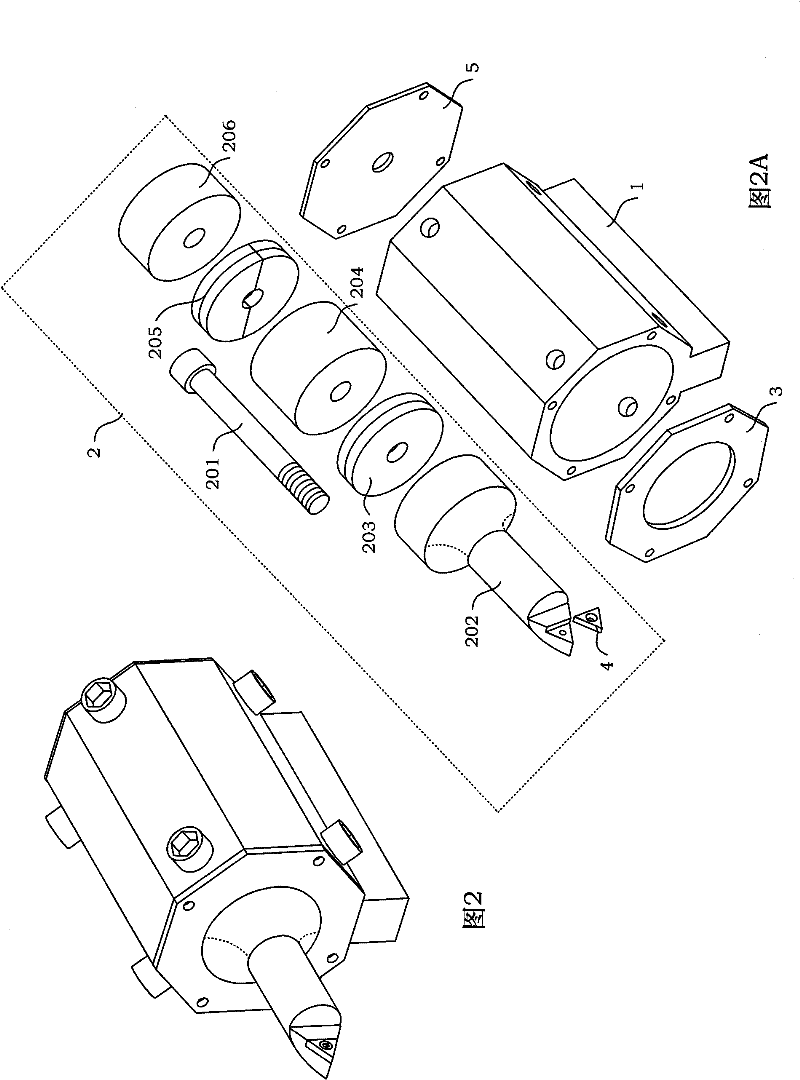

[0024] The present invention installs the matching ultrasonic elliptical vibration cutting device 30 in the CNC lathe, and then through the computer and the three-dimensional drawing software and lathe control software installed in the computer, the parts (or workpieces) to be processed are processed. Variable section control processing.

[0025] The present invention is a method for efficient and high-quality processing of slender shaft parts with large length-to-diameter ratio and variable cross-section based on ultrasonic elliptical vibration. The processing method includes the steps of pre-processing preparation and part processing:

[0026] (1) Preparation before processing

[0027] Step 1-1: Digitize the part configuration, use three-dimensional drawing software (such as CATIA / Autocad / Proe, etc.) to carry out the three-dimensional configuration of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com