Machining method for plastic movable composite member

A processing method and technology for moving parts, applied in the direction of coating, etc., can solve the problems of mutual rotation stuck, inconvenient use by customers, deformation of assemblies, etc., and achieve the effect of high product quality, smooth movement and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

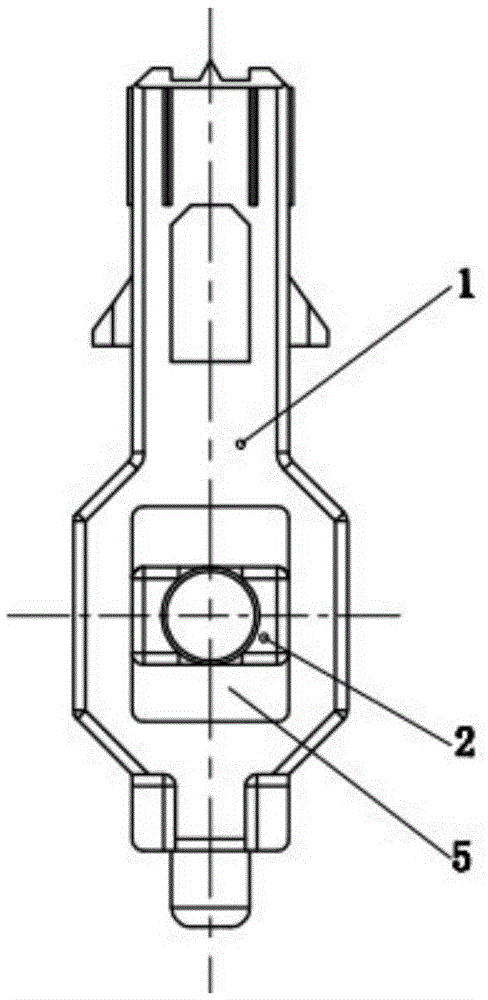

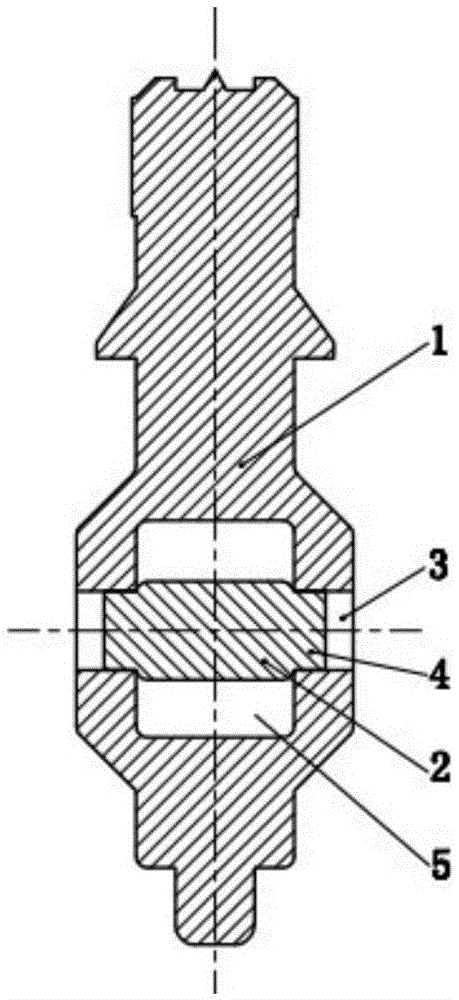

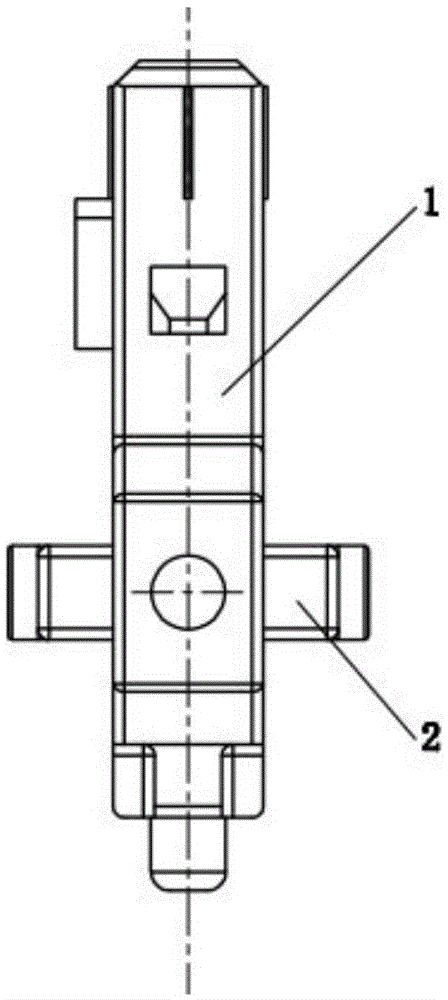

[0029] A processing method of a plastic movable assembly of the present invention, its specific implementation is described in terms of a processing method of a four-way cross shaft assembly, such as Figures 1 to 4 shown. It includes the following steps:

[0030] (1) Injection molding step of the first movable part: the first material is PA66GF30, and its molding shrinkage rate is 0.5%; the first material required for molding the first movable part 1 is heated to above 270-290°C to make it into a liquid state , and then injected into the first mold;

[0031] (2) Cooling step of the first movable part: cooling the first material in the first mold to form the first movable part 1; the first movable part 1 is the first shaft of the four-way cross shaft assembly, wherein A through hole 5 is opened at the top; the cross-sectional shape of the through hole 5 is a rectangle, and a limiting hole 3 is respectively arranged on the two side walls parallel to the axial direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com