Bolt machining method

A processing method and bolt technology, which is applied to screws, threaded fasteners, connecting components, etc., can solve problems such as time-consuming, complicated manufacturing process steps, and cumbersome manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

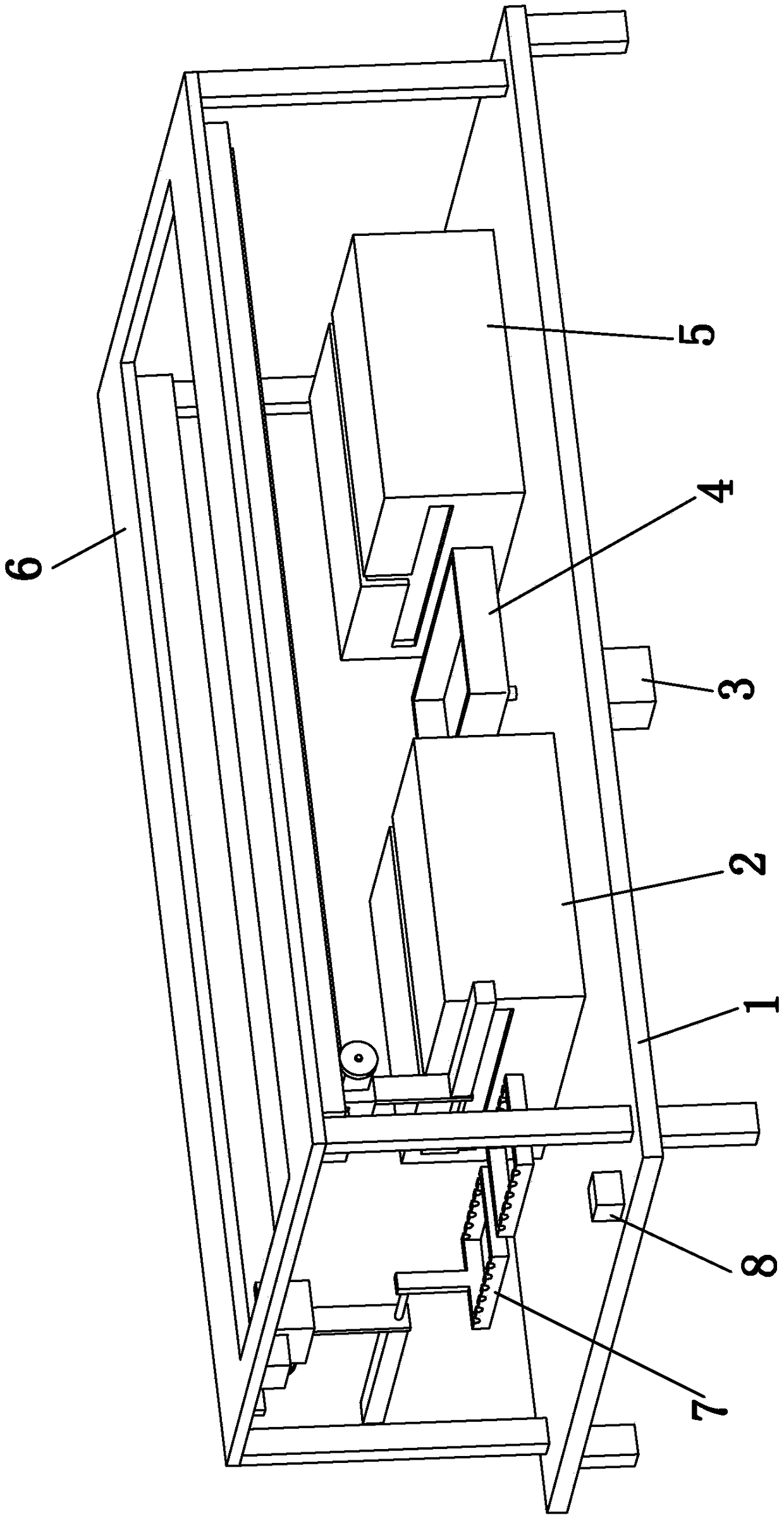

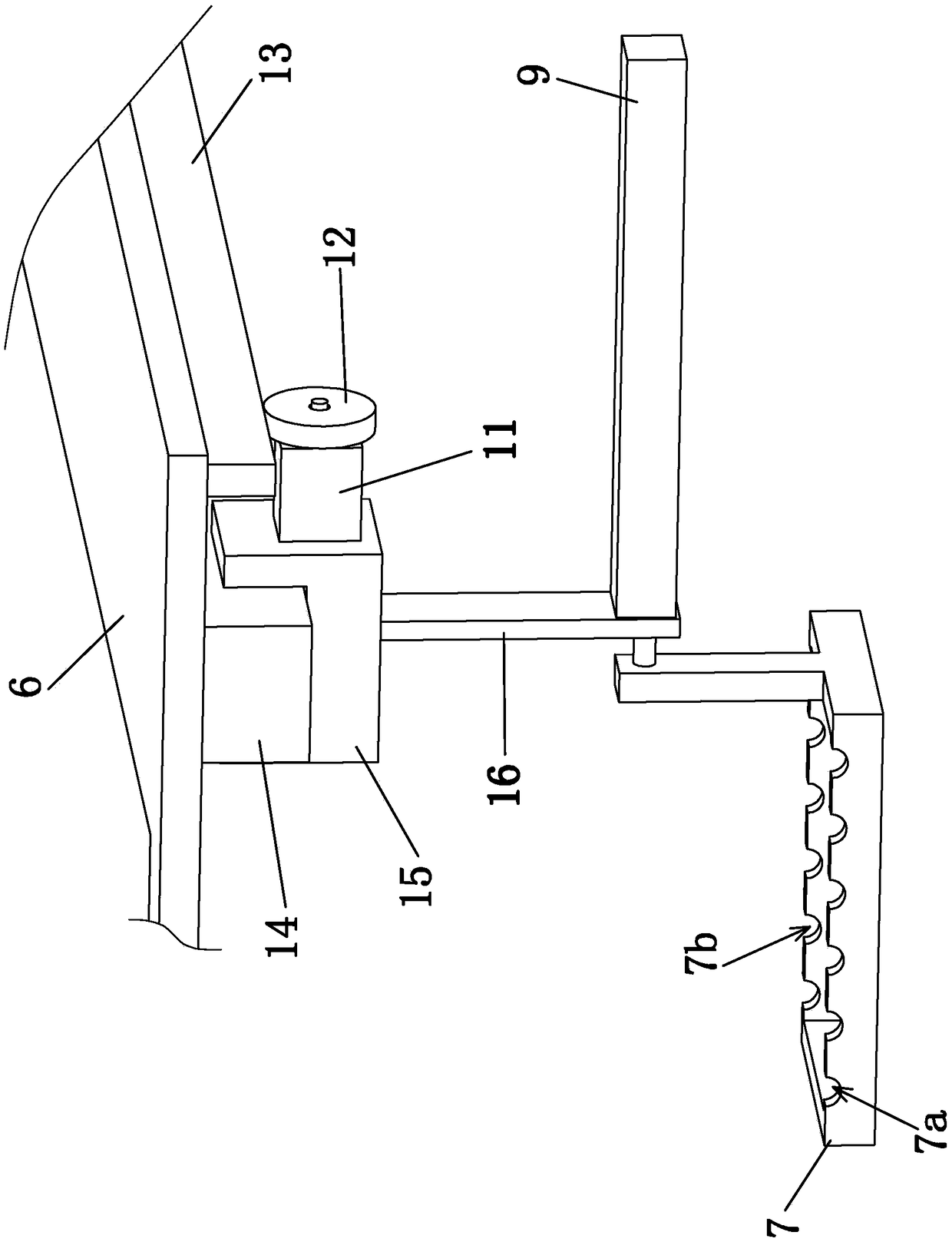

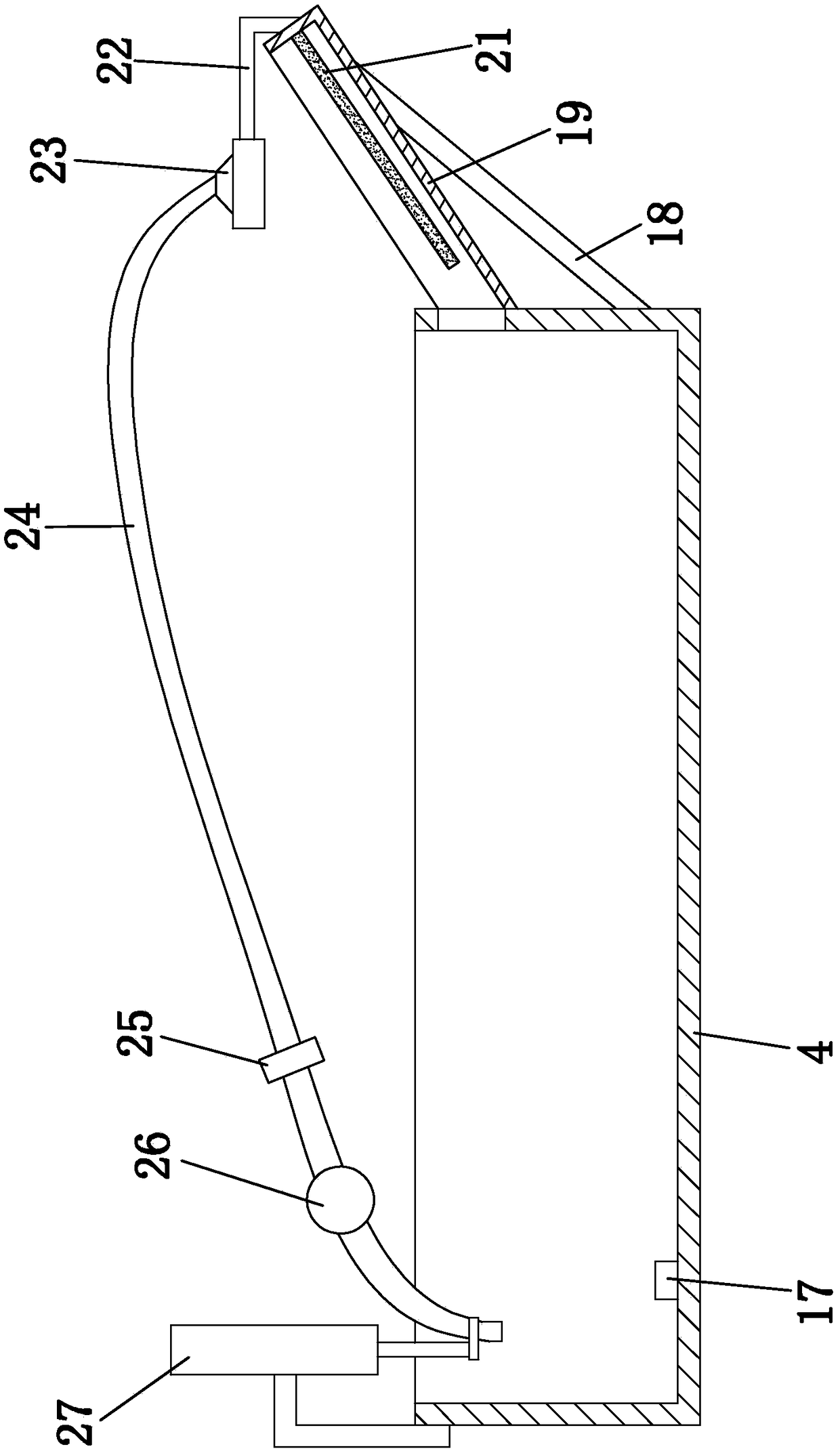

[0074] Below are specific embodiments of the present invention and in conjunction with accompanying drawing, technical scheme of the present invention is described further, but the present invention is not limited to these embodiments.

[0075] The processing method of this bolt comprises the following steps:

[0076] a. Material selection: Purchasing alloy steel material as coil material, the carbon content in the alloy steel material is 0.32-0.39%, the silicon content is 0.18-0.32%, the manganese content is 0.65-0.95%, and the phosphorus content is 0.02-0.03 %, the sulfur content is 0.01-0.02%, the chromium content is 0.74-1.13%, the copper content is 0.25-0.35, the boron content is 0.01-0.02%, the molybdenum content is 0.17-0.34%, and the rest is iron; In this embodiment, the alloy steel material is purchased as the coil material. The carbon content in the alloy steel material is 0.35%, the silicon content is 0.23%, the manganese content is 0.79%, the phosphorus content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Spray thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com