Synthetic polyisoprene rubber plug for injection and preparation method thereof

A technology of polyisoprene rubber stopper and polyisoprene, which is applied in the direction of hypodermic injection devices, etc., can solve problems such as poor resilience, leakage of liquid when pulling out needles, waste of labor and energy consumption, etc., and achieve good elasticity, Stable performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

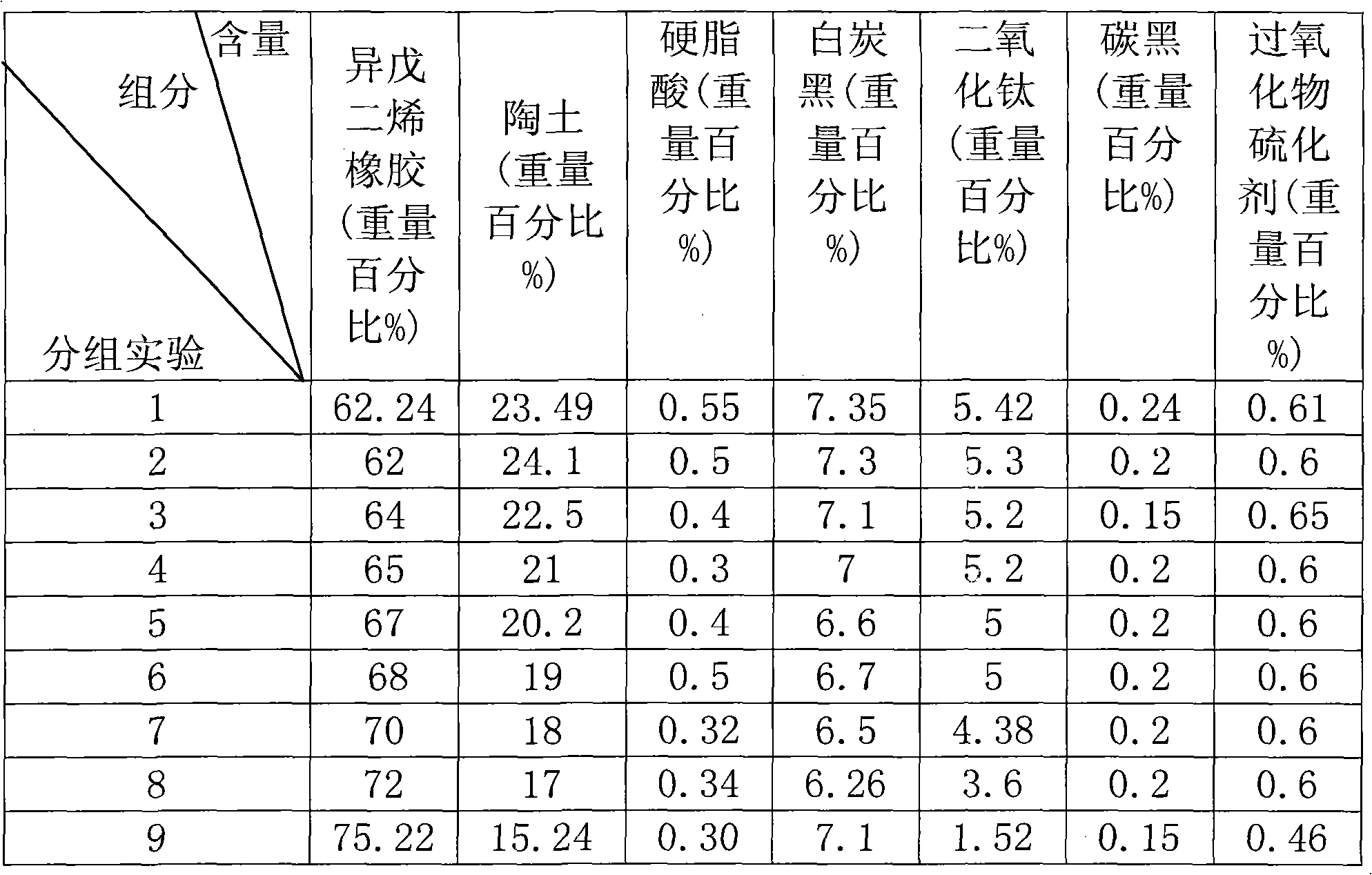

Examples

preparation example Construction

[0040] Specifically, the preparation method of the above-mentioned synthetic polyisoprene rubber stopper for injection comprises the following steps:

[0041] a. Weighing and banburying: Weigh the raw materials, put the weighed isoprene rubber in the internal mixer, first carry out half-pressure mastication, and then carry out full-pressure mastication, and then add stearic acid, titanium dioxide and carbon Black for rubber mixing, then add clay and white carbon black for rubber mixing and sweeping, continue rubber mixing after sweeping, and discharge after rubber mixing. Specifically include: turn on the internal mixer to heat up, when the temperature of the internal mixing chamber rises to 38°C ± 1°C, put in isoprene rubber, first half-pressure masticate for 30 seconds ± 5 seconds, then full-pressure masticate for 60 seconds ± 5 seconds; add stearic acid, titanium dioxide and carbon black, and mix the rubber for 90 seconds ± 5 seconds; add clay and white carbon black, mix th...

Embodiment 1

[0052] Weigh 61.24% of isoprene rubber, 24.49% of clay, 0.55% of stearic acid, 7.35% of white carbon black, 5.42% of titanium dioxide, 0.24% of carbon black and 0.61% of peroxide curing agent, Preparation of synthetic polyisoprene rubber stopper products.

[0053] The specific process is as follows:

[0054] a1. Weighing and internal mixing: Weigh the raw materials, turn on the internal mixer to heat up, and when the temperature of the internal mixing room rises to 38°C, put in isoprene rubber, first half-pressure masticating for 30 seconds, and then full-pressure masticating 60 seconds; add stearic acid, titanium dioxide and carbon black, and mix the rubber for 90 seconds; add clay and white carbon black, and sweep the rubber after 60 seconds of rubber mixing; after sweeping, continue to mix the rubber for 60 seconds; open the internal mixer room Discharge the mixed rubber, and the discharge temperature is about 40°C;

[0055] b1. Opening and extruding: Turn on the open mix...

Embodiment 2

[0063] Weigh 70% of isoprene rubber, 20% of clay, 0.4% of stearic acid, 7% of white carbon black, 1.9% of titanium dioxide, 0.2% of carbon black and 0.5% of peroxide curing agent, Preparation of synthetic polyisoprene rubber stopper products.

[0064] The specific process is as follows:

[0065] a1. Weighing and internal mixing: Weigh the raw materials, turn on the internal mixer to heat up, and when the temperature of the internal mixing room rises to 39°C, put in isoprene rubber, first half-pressure masticating for 35 seconds, and then full-pressure masticating 65 seconds; add stearic acid, titanium dioxide and carbon black, and mix the rubber for 95 seconds; add clay and white carbon black, and sweep the rubber after 65 seconds of rubber mixing; after sweeping, continue to mix the rubber for 65 seconds; open the internal mixer room Discharge the mixed rubber, and the discharge temperature is about 43°C;

[0066] b1. Opening and extruding: Turn on the open mixer to heat up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com